Are you a seasoned Induction Machine Operator seeking a new career path? Discover our professionally built Induction Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

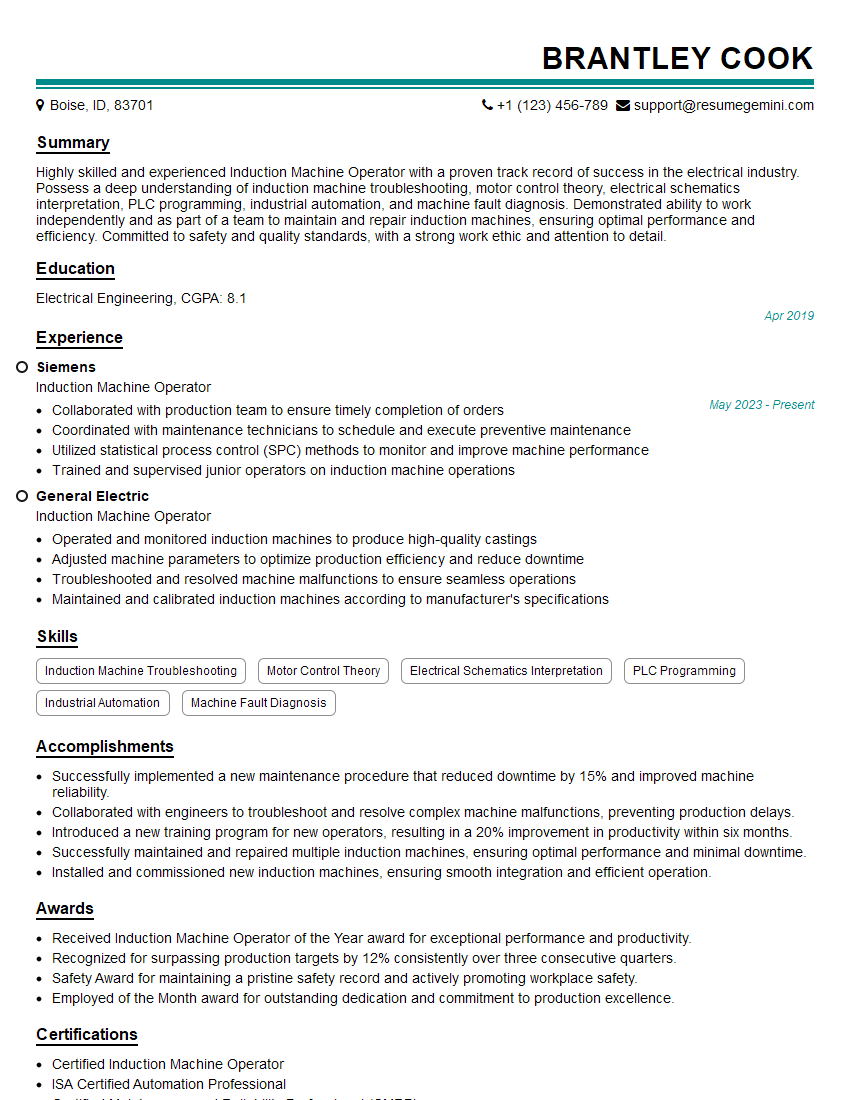

Brantley Cook

Induction Machine Operator

Summary

Highly skilled and experienced Induction Machine Operator with a proven track record of success in the electrical industry. Possess a deep understanding of induction machine troubleshooting, motor control theory, electrical schematics interpretation, PLC programming, industrial automation, and machine fault diagnosis. Demonstrated ability to work independently and as part of a team to maintain and repair induction machines, ensuring optimal performance and efficiency. Committed to safety and quality standards, with a strong work ethic and attention to detail.

Education

Electrical Engineering

April 2019

Skills

- Induction Machine Troubleshooting

- Motor Control Theory

- Electrical Schematics Interpretation

- PLC Programming

- Industrial Automation

- Machine Fault Diagnosis

Work Experience

Induction Machine Operator

- Collaborated with production team to ensure timely completion of orders

- Coordinated with maintenance technicians to schedule and execute preventive maintenance

- Utilized statistical process control (SPC) methods to monitor and improve machine performance

- Trained and supervised junior operators on induction machine operations

Induction Machine Operator

- Operated and monitored induction machines to produce high-quality castings

- Adjusted machine parameters to optimize production efficiency and reduce downtime

- Troubleshooted and resolved machine malfunctions to ensure seamless operations

- Maintained and calibrated induction machines according to manufacturer’s specifications

Accomplishments

- Successfully implemented a new maintenance procedure that reduced downtime by 15% and improved machine reliability.

- Collaborated with engineers to troubleshoot and resolve complex machine malfunctions, preventing production delays.

- Introduced a new training program for new operators, resulting in a 20% improvement in productivity within six months.

- Successfully maintained and repaired multiple induction machines, ensuring optimal performance and minimal downtime.

- Installed and commissioned new induction machines, ensuring smooth integration and efficient operation.

Awards

- Received Induction Machine Operator of the Year award for exceptional performance and productivity.

- Recognized for surpassing production targets by 12% consistently over three consecutive quarters.

- Safety Award for maintaining a pristine safety record and actively promoting workplace safety.

- Employed of the Month award for outstanding dedication and commitment to production excellence.

Certificates

- Certified Induction Machine Operator

- ISA Certified Automation Professional

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Induction Machine Operator

- Highlight your technical skills and experience in induction machine operation and maintenance.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact.

- Showcase your problem-solving abilities and provide examples of successful troubleshooting and repair projects.

- Emphasize your commitment to safety and quality standards, including any relevant certifications or training.

- Utilize keywords relevant to the job market, such as ‘induction machine,’ ‘troubleshooting,’ ‘PLC programming,’ and ‘industrial automation.’

Essential Experience Highlights for a Strong Induction Machine Operator Resume

- Troubleshoot and repair induction machines to identify and resolve issues, ensuring optimal performance.

- Interpret electrical schematics and diagrams to understand machine wiring and functionality.

- Program and configure PLCs (Programmable Logic Controllers) to automate machine processes and improve efficiency.

- Diagnose machine faults using diagnostic tools and techniques, determining root causes and implementing corrective actions.

- Conduct preventive maintenance tasks, including lubrication, inspection, and testing, to extend machine life and minimize downtime.

- Work with other technicians and engineers to resolve complex machine issues and develop innovative solutions.

- Adhere to safety protocols and maintain a clean and organized work area to ensure a safe and efficient work environment.

Frequently Asked Questions (FAQ’s) For Induction Machine Operator

What is the role of an Induction Machine Operator?

An Induction Machine Operator is responsible for the operation, maintenance, and repair of induction machines used in industrial settings. They troubleshoot and diagnose machine faults, interpret electrical schematics, program PLCs, and perform preventive maintenance tasks to ensure optimal machine performance and efficiency.

What skills are required to be an Induction Machine Operator?

Induction Machine Operators typically require a strong understanding of induction machine troubleshooting, motor control theory, electrical schematics interpretation, PLC programming, industrial automation, and machine fault diagnosis. They should also possess excellent problem-solving skills and a commitment to safety and quality standards.

What are the career prospects for Induction Machine Operators?

Induction Machine Operators can advance their careers by gaining experience and developing specialized skills in areas such as PLC programming, industrial automation, or machine fault diagnosis. They may also pursue management roles or become trainers or consultants in the field.

What is the work environment like for Induction Machine Operators?

Induction Machine Operators typically work in industrial settings, such as factories or manufacturing plants. They may work independently or as part of a team, and may be required to work shifts or overtime to meet production demands.

What are the safety considerations for Induction Machine Operators?

Induction Machine Operators must adhere to strict safety protocols to prevent accidents or injuries. They should wear appropriate personal protective equipment, follow lockout/tagout procedures, and be aware of potential hazards such as electrical shock, moving machinery, and hazardous chemicals.

What is the average salary for Induction Machine Operators?

The average salary for Induction Machine Operators varies depending on factors such as experience, location, and industry. According to Indeed, the average salary for Induction Machine Operators in the United States is around $65,000 per year.

What are the key trends in Induction Machine Operation?

Key trends in Induction Machine Operation include the increasing use of automation and predictive maintenance technologies to improve efficiency and reduce downtime. Additionally, there is a growing focus on energy efficiency and sustainability in the industrial sector, which is driving demand for Induction Machine Operators with expertise in energy-saving techniques.

What are the challenges faced by Induction Machine Operators?

Induction Machine Operators face challenges such as working with complex machinery, diagnosing and repairing faults under time pressure, and ensuring the safety of themselves and others in a potentially hazardous work environment.