Are you a seasoned Industrial Coating and Lining Application Specialist seeking a new career path? Discover our professionally built Industrial Coating and Lining Application Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

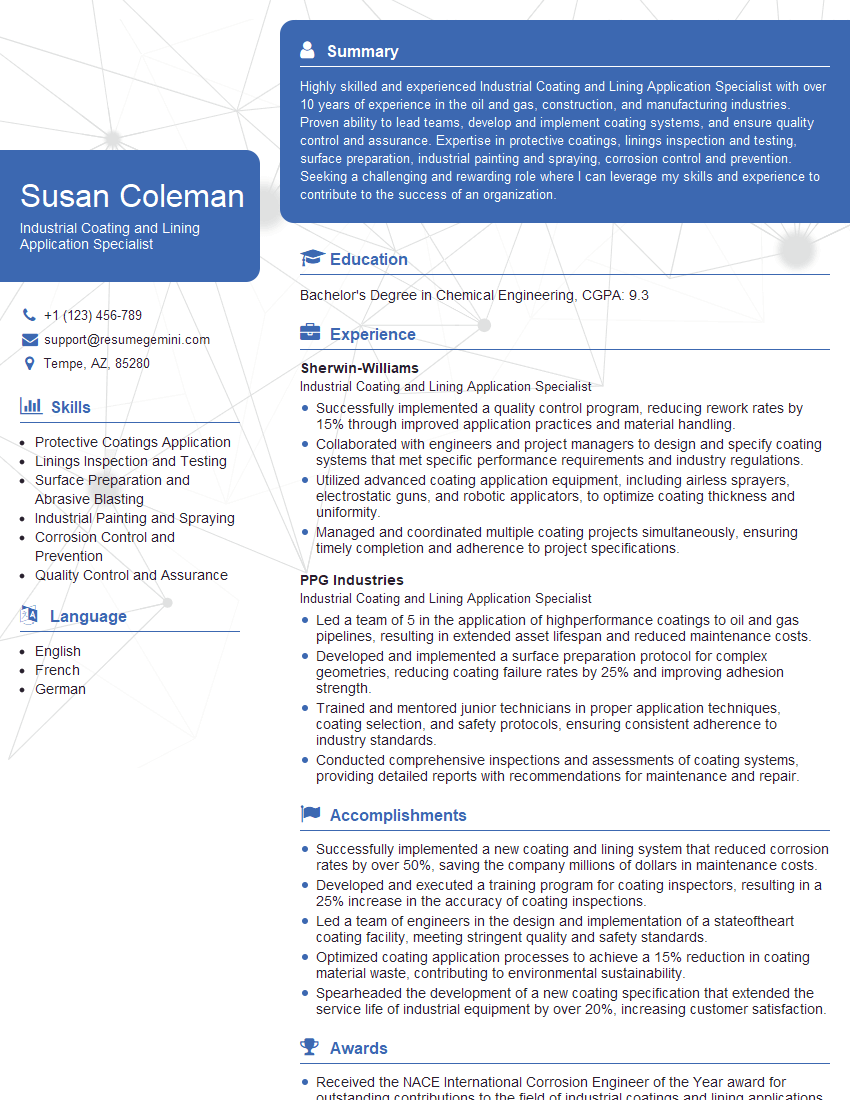

Susan Coleman

Industrial Coating and Lining Application Specialist

Summary

Highly skilled and experienced Industrial Coating and Lining Application Specialist with over 10 years of experience in the oil and gas, construction, and manufacturing industries. Proven ability to lead teams, develop and implement coating systems, and ensure quality control and assurance. Expertise in protective coatings, linings inspection and testing, surface preparation, industrial painting and spraying, corrosion control and prevention. Seeking a challenging and rewarding role where I can leverage my skills and experience to contribute to the success of an organization.

Education

Bachelor’s Degree in Chemical Engineering

June 2018

Skills

- Protective Coatings Application

- Linings Inspection and Testing

- Surface Preparation and Abrasive Blasting

- Industrial Painting and Spraying

- Corrosion Control and Prevention

- Quality Control and Assurance

Work Experience

Industrial Coating and Lining Application Specialist

- Successfully implemented a quality control program, reducing rework rates by 15% through improved application practices and material handling.

- Collaborated with engineers and project managers to design and specify coating systems that met specific performance requirements and industry regulations.

- Utilized advanced coating application equipment, including airless sprayers, electrostatic guns, and robotic applicators, to optimize coating thickness and uniformity.

- Managed and coordinated multiple coating projects simultaneously, ensuring timely completion and adherence to project specifications.

Industrial Coating and Lining Application Specialist

- Led a team of 5 in the application of highperformance coatings to oil and gas pipelines, resulting in extended asset lifespan and reduced maintenance costs.

- Developed and implemented a surface preparation protocol for complex geometries, reducing coating failure rates by 25% and improving adhesion strength.

- Trained and mentored junior technicians in proper application techniques, coating selection, and safety protocols, ensuring consistent adherence to industry standards.

- Conducted comprehensive inspections and assessments of coating systems, providing detailed reports with recommendations for maintenance and repair.

Accomplishments

- Successfully implemented a new coating and lining system that reduced corrosion rates by over 50%, saving the company millions of dollars in maintenance costs.

- Developed and executed a training program for coating inspectors, resulting in a 25% increase in the accuracy of coating inspections.

- Led a team of engineers in the design and implementation of a stateoftheart coating facility, meeting stringent quality and safety standards.

- Optimized coating application processes to achieve a 15% reduction in coating material waste, contributing to environmental sustainability.

- Spearheaded the development of a new coating specification that extended the service life of industrial equipment by over 20%, increasing customer satisfaction.

Awards

- Received the NACE International Corrosion Engineer of the Year award for outstanding contributions to the field of industrial coatings and lining applications.

- Honored with the Society for Protective Coatings Excellence in Protective Coatings award for innovative use of protective coatings in harsh industrial environments.

- Recognized with the Industrial Coating Manufacturers Association Technical Achievement Award for developing a groundbreaking coating system that significantly extended the lifespan of industrial assets.

- Awarded the American Coating Association Technical Innovation Award for developing a novel coating technology that improved adhesion and durability on concrete surfaces.

Certificates

- National Association of Corrosion Engineers (NACE) Coating Inspector (CIP)

- American Water Works Association (AWWA) Water Storage Inspector

- Society for Protective Coatings (SSPC) Tank Lining Specialist

- National Institute for Certification in Engineering Technologies (NICET) Water Treatment and Distribution Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Coating and Lining Application Specialist

- Highlight your technical skills and experience in protective coatings, linings, surface preparation, and coating application.

- Showcase your ability to lead teams, manage projects, and ensure quality control and assurance.

- Quantify your accomplishments with specific examples and metrics whenever possible.

- Tailor your resume to each job description you apply for, highlighting the skills and experience most relevant to the position.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Industrial Coating and Lining Application Specialist Resume

- Led and managed teams of coating applicators in the application of high-performance coatings to industrial structures, equipment, and pipelines.

- Developed and implemented surface preparation protocols for complex geometries, resulting in improved coating adhesion and reduced failure rates.

- Conducted comprehensive inspections and assessments of coating systems, providing detailed reports with recommendations for maintenance and repair.

- Collaborated with engineers and project managers to design and specify coating systems that met specific performance requirements and industry regulations.

- Utilized advanced coating application equipment and techniques to optimize coating thickness, uniformity, and adhesion.

- Managed and coordinated multiple coating projects simultaneously, ensuring timely completion and adherence to project specifications.

- Trained and mentored junior technicians in proper application techniques, coating selection, and safety protocols, ensuring consistent adherence to industry standards.

Frequently Asked Questions (FAQ’s) For Industrial Coating and Lining Application Specialist

What are the key skills required for an Industrial Coating and Lining Application Specialist?

The key skills required for an Industrial Coating and Lining Application Specialist include: protective coatings application, linings inspection and testing, surface preparation and abrasive blasting, industrial painting and spraying, corrosion control and prevention, quality control and assurance, and safety protocols.

What are the typical responsibilities of an Industrial Coating and Lining Application Specialist?

The typical responsibilities of an Industrial Coating and Lining Application Specialist include: applying protective coatings to industrial structures, equipment, and pipelines; inspecting and testing coatings; developing and implementing surface preparation protocols; collaborating with engineers and project managers to design and specify coating systems; and training and mentoring junior technicians.

What are the career prospects for an Industrial Coating and Lining Application Specialist?

The career prospects for an Industrial Coating and Lining Application Specialist are good. There is a growing demand for skilled coating applicators in the oil and gas, construction, and manufacturing industries. With experience, Industrial Coating and Lining Application Specialists can advance to supervisory or management positions.

What is the salary range for an Industrial Coating and Lining Application Specialist?

The salary range for an Industrial Coating and Lining Application Specialist can vary depending on experience, location, and employer. According to Indeed, the average salary for an Industrial Coating and Lining Application Specialist in the United States is $65,000 per year.

What are the educational requirements for an Industrial Coating and Lining Application Specialist?

The educational requirements for an Industrial Coating and Lining Application Specialist typically include a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as chemical engineering or materials science.

What are the certification requirements for an Industrial Coating and Lining Application Specialist?

There are no formal certification requirements for an Industrial Coating and Lining Application Specialist. However, some employers may prefer candidates with certifications from organizations such as the National Association of Corrosion Engineers (NACE) or the Society for Protective Coatings (SSPC).

What are the safety considerations for an Industrial Coating and Lining Application Specialist?

Industrial Coating and Lining Application Specialists must adhere to strict safety protocols when working with hazardous materials and equipment. This includes wearing proper protective gear, following proper mixing and application procedures, and ensuring adequate ventilation.

What are the challenges faced by Industrial Coating and Lining Application Specialists?

Industrial Coating and Lining Application Specialists can face a number of challenges, including working with hazardous materials, working in confined spaces, and meeting tight deadlines. They must also be able to work independently and as part of a team.