Are you a seasoned Industrial Insulator seeking a new career path? Discover our professionally built Industrial Insulator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

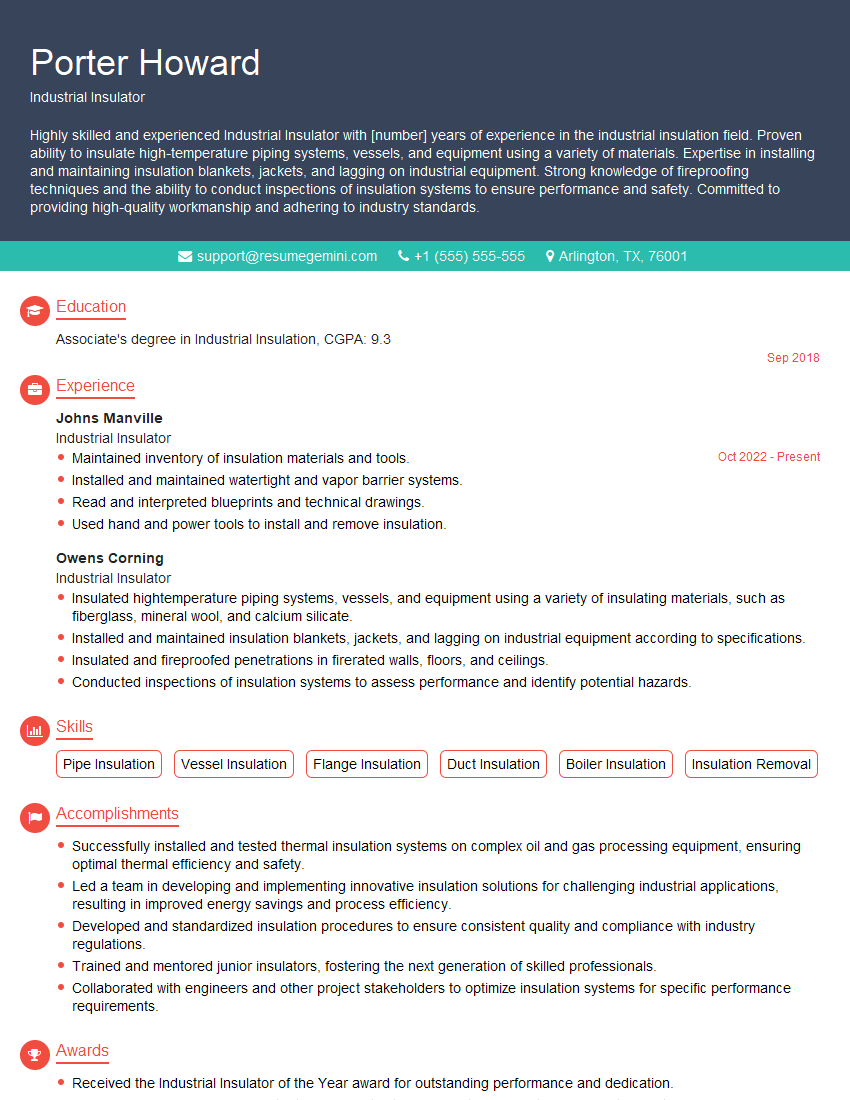

Porter Howard

Industrial Insulator

Summary

Highly skilled and experienced Industrial Insulator with [number] years of experience in the industrial insulation field. Proven ability to insulate high-temperature piping systems, vessels, and equipment using a variety of materials. Expertise in installing and maintaining insulation blankets, jackets, and lagging on industrial equipment. Strong knowledge of fireproofing techniques and the ability to conduct inspections of insulation systems to ensure performance and safety. Committed to providing high-quality workmanship and adhering to industry standards.

Education

Associate’s degree in Industrial Insulation

September 2018

Skills

- Pipe Insulation

- Vessel Insulation

- Flange Insulation

- Duct Insulation

- Boiler Insulation

- Insulation Removal

Work Experience

Industrial Insulator

- Maintained inventory of insulation materials and tools.

- Installed and maintained watertight and vapor barrier systems.

- Read and interpreted blueprints and technical drawings.

- Used hand and power tools to install and remove insulation.

Industrial Insulator

- Insulated hightemperature piping systems, vessels, and equipment using a variety of insulating materials, such as fiberglass, mineral wool, and calcium silicate.

- Installed and maintained insulation blankets, jackets, and lagging on industrial equipment according to specifications.

- Insulated and fireproofed penetrations in firerated walls, floors, and ceilings.

- Conducted inspections of insulation systems to assess performance and identify potential hazards.

Accomplishments

- Successfully installed and tested thermal insulation systems on complex oil and gas processing equipment, ensuring optimal thermal efficiency and safety.

- Led a team in developing and implementing innovative insulation solutions for challenging industrial applications, resulting in improved energy savings and process efficiency.

- Developed and standardized insulation procedures to ensure consistent quality and compliance with industry regulations.

- Trained and mentored junior insulators, fostering the next generation of skilled professionals.

- Collaborated with engineers and other project stakeholders to optimize insulation systems for specific performance requirements.

Awards

- Received the Industrial Insulator of the Year award for outstanding performance and dedication.

- Recognized for achieving consistently highquality standards in the application of insulation materials.

- Commended for exceptional attention to detail and meticulous craftsmanship in the installation of insulation systems.

- Honored for contributions to the development and promotion of best practices in the Industrial Insulation field.

Certificates

- Insulation Installer Certification (IIC)

- Certified Insulation Inspector (CII)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Industrial Insulator (CII)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Insulator

- Highlight your experience and skills in working with different types of insulation materials.

- Showcase your knowledge of fireproofing techniques and industry standards.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Include keywords related to industrial insulation, such as pipe insulation, vessel insulation, and flange insulation.

Essential Experience Highlights for a Strong Industrial Insulator Resume

- Insulated high-temperature piping systems, vessels, and equipment using various materials, including fiberglass, mineral wool, and calcium silicate.

- Installed and maintained insulation blankets, jackets, and lagging on industrial equipment according to specifications.

- Insulated and fireproofed penetrations in fire-rated walls, floors, and ceilings.

- Conducted inspections of insulation systems to assess performance and identify potential hazards.

- Installed and maintained watertight and vapor barrier systems.

- Read and interpreted blueprints and technical drawings.

- Used hand and power tools to install and remove insulation.

Frequently Asked Questions (FAQ’s) For Industrial Insulator

What are the primary responsibilities of an Industrial Insulator?

Industrial Insulators are responsible for installing, maintaining, and inspecting insulation systems on industrial equipment and structures. They work with various insulation materials, including fiberglass, mineral wool, and calcium silicate, to ensure efficient temperature control, energy conservation, and safety.

What qualifications are required to become an Industrial Insulator?

Most Industrial Insulators have an associate’s degree or certification in industrial insulation. They should also have a strong understanding of insulation materials, fireproofing techniques, and industry standards.

What are the career prospects for Industrial Insulators?

Industrial Insulators are in high demand due to the increasing need for energy efficiency and safety in industrial settings. They can work in various industries, including manufacturing, construction, and energy.

What are the key skills required for Industrial Insulators?

Industrial Insulators should have strong technical skills, including the ability to read and interpret blueprints, use hand and power tools, and work with different insulation materials. They should also have a good understanding of fireproofing techniques and safety regulations.

What are the different types of insulation materials used by Industrial Insulators?

Industrial Insulators work with various insulation materials, including fiberglass, mineral wool, calcium silicate, polystyrene, and polyurethane. Each material has unique properties and applications, and Industrial Insulators must be familiar with their characteristics to select the appropriate material for each project.

What are the safety precautions that Industrial Insulators must follow?

Industrial Insulators work with potentially hazardous materials and equipment, so they must follow strict safety precautions. These precautions include wearing appropriate personal protective equipment, being aware of potential hazards, and following established safety protocols.

What are the latest trends in the Industrial Insulation industry?

The Industrial Insulation industry is constantly evolving as new materials and technologies emerge. Some of the latest trends include the use of sustainable and eco-friendly insulation materials, the development of more efficient insulation systems, and the integration of smart technologies into insulation systems.

What professional development opportunities are available for Industrial Insulators?

Industrial Insulators can enhance their skills and knowledge through various professional development opportunities. These opportunities include attending industry conferences, webinars, and workshops, obtaining certifications, and pursuing higher education.