Are you a seasoned Industrial Methods Consultant seeking a new career path? Discover our professionally built Industrial Methods Consultant Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

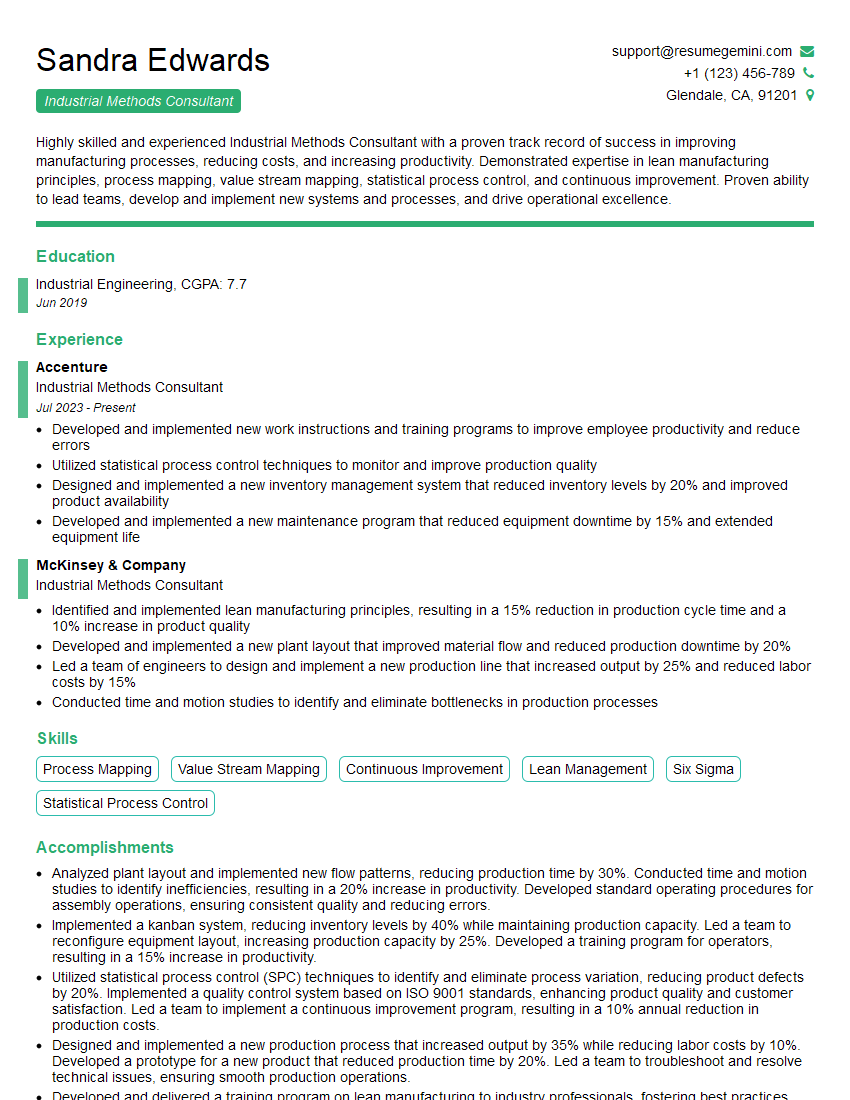

Sandra Edwards

Industrial Methods Consultant

Summary

Highly skilled and experienced Industrial Methods Consultant with a proven track record of success in improving manufacturing processes, reducing costs, and increasing productivity. Demonstrated expertise in lean manufacturing principles, process mapping, value stream mapping, statistical process control, and continuous improvement. Proven ability to lead teams, develop and implement new systems and processes, and drive operational excellence.

Education

Industrial Engineering

June 2019

Skills

- Process Mapping

- Value Stream Mapping

- Continuous Improvement

- Lean Management

- Six Sigma

- Statistical Process Control

Work Experience

Industrial Methods Consultant

- Developed and implemented new work instructions and training programs to improve employee productivity and reduce errors

- Utilized statistical process control techniques to monitor and improve production quality

- Designed and implemented a new inventory management system that reduced inventory levels by 20% and improved product availability

- Developed and implemented a new maintenance program that reduced equipment downtime by 15% and extended equipment life

Industrial Methods Consultant

- Identified and implemented lean manufacturing principles, resulting in a 15% reduction in production cycle time and a 10% increase in product quality

- Developed and implemented a new plant layout that improved material flow and reduced production downtime by 20%

- Led a team of engineers to design and implement a new production line that increased output by 25% and reduced labor costs by 15%

- Conducted time and motion studies to identify and eliminate bottlenecks in production processes

Accomplishments

- Analyzed plant layout and implemented new flow patterns, reducing production time by 30%. Conducted time and motion studies to identify inefficiencies, resulting in a 20% increase in productivity. Developed standard operating procedures for assembly operations, ensuring consistent quality and reducing errors.

- Implemented a kanban system, reducing inventory levels by 40% while maintaining production capacity. Led a team to reconfigure equipment layout, increasing production capacity by 25%. Developed a training program for operators, resulting in a 15% increase in productivity.

- Utilized statistical process control (SPC) techniques to identify and eliminate process variation, reducing product defects by 20%. Implemented a quality control system based on ISO 9001 standards, enhancing product quality and customer satisfaction. Led a team to implement a continuous improvement program, resulting in a 10% annual reduction in production costs.

- Designed and implemented a new production process that increased output by 35% while reducing labor costs by 10%. Developed a prototype for a new product that reduced production time by 20%. Led a team to troubleshoot and resolve technical issues, ensuring smooth production operations.

- Developed and delivered a training program on lean manufacturing to industry professionals, fostering best practices. Published research papers on industrial methods engineering, advancing the fields knowledge base. Mentored young engineers, sharing expertise and promoting professional development.

Awards

- Recognized with Presidents Award for streamlining production processes, reducing costs by 15%.

- Received Excellence Award for developing a lean manufacturing program that eliminated waste and improved operational efficiency.

- Awarded the Six Sigma Black Belt certification for achieving significant process improvements in a manufacturing environment.

- Recognized with the Outstanding Engineer Award for developing innovative solutions to complex production challenges.

Certificates

- Certified Lean Six Sigma Black Belt

- Certified Value Stream Mapping Professional

- Certified Continuous Improvement Professional

- Certified Manufacturing Engineer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Methods Consultant

- Quantify your accomplishments with specific metrics and percentages whenever possible.

- Highlight your experience in implementing specific lean manufacturing principles and tools, such as value stream mapping and Kaizen events.

- Showcase your ability to lead and motivate teams to achieve operational excellence.

- Demonstrate your knowledge of statistical process control and your ability to use data to improve processes.

- Emphasize your communication and interpersonal skills, as well as your ability to work effectively with cross-functional teams.

Essential Experience Highlights for a Strong Industrial Methods Consultant Resume

- Identify and implement lean manufacturing principles to improve production efficiency and quality.

- Develop and implement new plant layouts and production lines to optimize material flow and reduce downtime.

- Conduct time and motion studies to identify and eliminate bottlenecks in production processes.

- Develop and implement new work instructions and training programs to improve employee productivity and reduce errors.

- Utilize statistical process control techniques to monitor and improve production quality.

- Design and implement new inventory management systems to reduce inventory levels and improve product availability.

- Develop and implement new maintenance programs to reduce equipment downtime and extend equipment life.

Frequently Asked Questions (FAQ’s) For Industrial Methods Consultant

What is the role of an Industrial Methods Consultant?

An Industrial Methods Consultant is responsible for identifying and implementing improvements to manufacturing processes. They work with clients to analyze existing processes, identify areas for improvement, and develop and implement solutions to increase efficiency, reduce costs, and improve quality.

What skills are required to be an Industrial Methods Consultant?

Industrial Methods Consultants typically have a background in industrial engineering or a related field. They have a strong understanding of lean manufacturing principles, process mapping, value stream mapping, statistical process control, and continuous improvement. They also have excellent communication and interpersonal skills, and are able to work effectively with cross-functional teams.

What are the benefits of hiring an Industrial Methods Consultant?

Hiring an Industrial Methods Consultant can provide a number of benefits, including: improved production efficiency, reduced costs, increased product quality, and improved employee productivity.

How much does an Industrial Methods Consultant cost?

The cost of hiring an Industrial Methods Consultant can vary depending on the size and complexity of the project.

What is the job outlook for Industrial Methods Consultants?

The job outlook for Industrial Methods Consultants is expected to be good in the coming years.

Where can I find more information about Industrial Methods Consultants?

There are a number of resources available online about Industrial Methods Consultants, including the website of the Association for Manufacturing Excellence (AME) and the website of the Institute of Industrial Engineers (IIE).