Are you a seasoned Industrial Multicraft Maintenance Technician seeking a new career path? Discover our professionally built Industrial Multicraft Maintenance Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

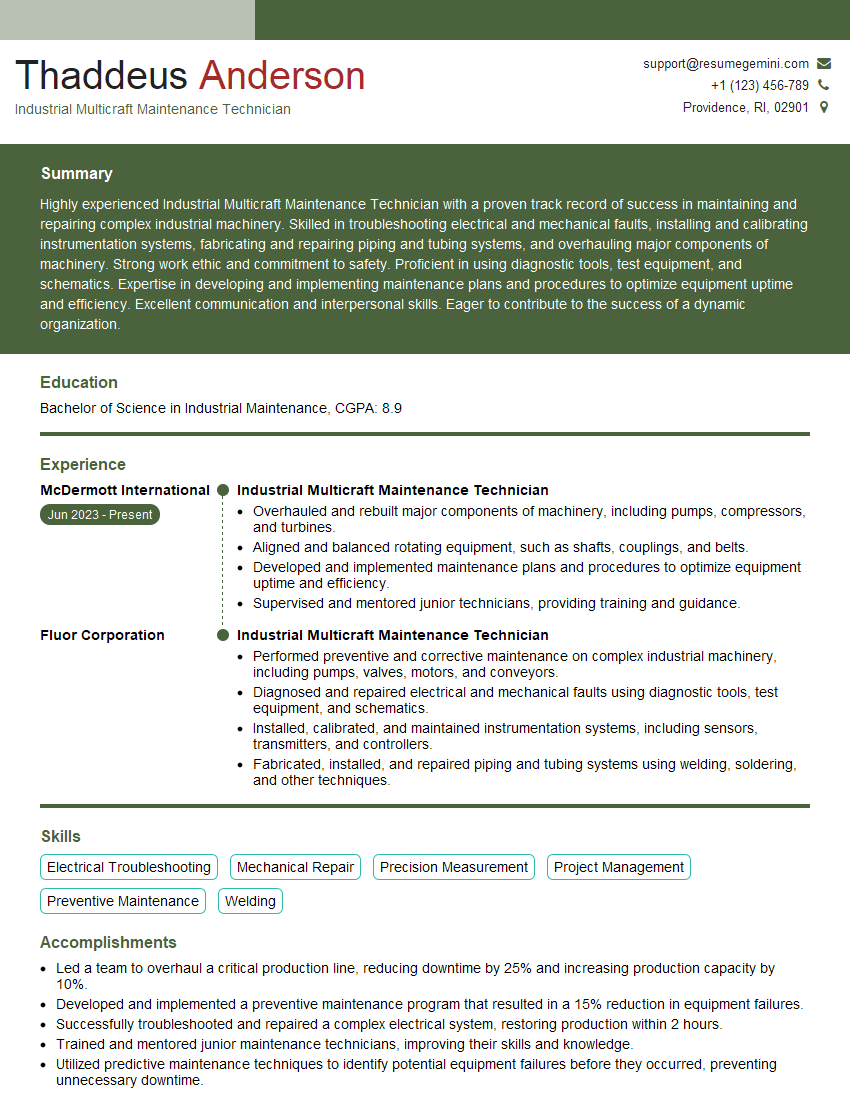

Thaddeus Anderson

Industrial Multicraft Maintenance Technician

Summary

Highly experienced Industrial Multicraft Maintenance Technician with a proven track record of success in maintaining and repairing complex industrial machinery. Skilled in troubleshooting electrical and mechanical faults, installing and calibrating instrumentation systems, fabricating and repairing piping and tubing systems, and overhauling major components of machinery. Strong work ethic and commitment to safety. Proficient in using diagnostic tools, test equipment, and schematics. Expertise in developing and implementing maintenance plans and procedures to optimize equipment uptime and efficiency. Excellent communication and interpersonal skills. Eager to contribute to the success of a dynamic organization.

Education

Bachelor of Science in Industrial Maintenance

May 2019

Skills

- Electrical Troubleshooting

- Mechanical Repair

- Precision Measurement

- Project Management

- Preventive Maintenance

- Welding

Work Experience

Industrial Multicraft Maintenance Technician

- Overhauled and rebuilt major components of machinery, including pumps, compressors, and turbines.

- Aligned and balanced rotating equipment, such as shafts, couplings, and belts.

- Developed and implemented maintenance plans and procedures to optimize equipment uptime and efficiency.

- Supervised and mentored junior technicians, providing training and guidance.

Industrial Multicraft Maintenance Technician

- Performed preventive and corrective maintenance on complex industrial machinery, including pumps, valves, motors, and conveyors.

- Diagnosed and repaired electrical and mechanical faults using diagnostic tools, test equipment, and schematics.

- Installed, calibrated, and maintained instrumentation systems, including sensors, transmitters, and controllers.

- Fabricated, installed, and repaired piping and tubing systems using welding, soldering, and other techniques.

Accomplishments

- Led a team to overhaul a critical production line, reducing downtime by 25% and increasing production capacity by 10%.

- Developed and implemented a preventive maintenance program that resulted in a 15% reduction in equipment failures.

- Successfully troubleshooted and repaired a complex electrical system, restoring production within 2 hours.

- Trained and mentored junior maintenance technicians, improving their skills and knowledge.

- Utilized predictive maintenance techniques to identify potential equipment failures before they occurred, preventing unnecessary downtime.

Awards

- Received the Maintenance Technician of the Year award for exceptional performance and contributions to plant reliability.

- Recognized with the Safety Excellence Award for consistently maintaining a high level of safety standards in the workplace.

- Received the Innovation Award for designing and implementing a costeffective solution to an ongoing maintenance issue.

- Recognized as the Top Performer in the maintenance department for consistently exceeding performance expectations.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Precision Measurement Level II

- Certified Maintenance Manager (CMM)

- Reliability and Maintenance Engineering Specialist (RMES)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Multicraft Maintenance Technician

- Highlight your experience and skills in maintaining and repairing industrial machinery.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Use keywords that are relevant to the job you are applying for.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Industrial Multicraft Maintenance Technician Resume

- Perform preventive and corrective maintenance on complex industrial machinery

- Diagnose and repair electrical and mechanical faults using diagnostic tools, test equipment, and schematics

- Install, calibrate, and maintain instrumentation systems, including sensors, transmitters, and controllers

- Fabricate, install, and repair piping and tubing systems using welding, soldering, and other techniques

- Overhaul and rebuild major components of machinery, including pumps, compressors, and turbines

- Align and balance rotating equipment, such as shafts, couplings, and belts

- Develop and implement maintenance plans and procedures to optimize equipment uptime and efficiency

Frequently Asked Questions (FAQ’s) For Industrial Multicraft Maintenance Technician

What are the key responsibilities of an Industrial Multicraft Maintenance Technician?

The key responsibilities of an Industrial Multicraft Maintenance Technician include performing preventive and corrective maintenance on complex industrial machinery, diagnosing and repairing electrical and mechanical faults, installing and calibrating instrumentation systems, fabricating and repairing piping and tubing systems, overhauling major components of machinery, aligning and balancing rotating equipment, and developing and implementing maintenance plans and procedures.

What are the qualifications for an Industrial Multicraft Maintenance Technician?

The qualifications for an Industrial Multicraft Maintenance Technician typically include a high school diploma or equivalent, as well as several years of experience in industrial maintenance. Additional qualifications may include an associate degree or bachelor’s degree in a related field, such as industrial maintenance, mechanical engineering, or electrical engineering.

What are the skills required for an Industrial Multicraft Maintenance Technician?

The skills required for an Industrial Multicraft Maintenance Technician include troubleshooting electrical and mechanical faults, installing and calibrating instrumentation systems, fabricating and repairing piping and tubing systems, overhauling major components of machinery, aligning and balancing rotating equipment, and developing and implementing maintenance plans and procedures.

What is the work environment like for an Industrial Multicraft Maintenance Technician?

Industrial Multicraft Maintenance Technicians typically work in industrial settings, such as factories, power plants, and refineries. They may work indoors or outdoors, and they may be exposed to noise, dust, and other hazards.

What is the career outlook for an Industrial Multicraft Maintenance Technician?

The career outlook for Industrial Multicraft Maintenance Technicians is expected to be good. The demand for skilled maintenance technicians is expected to grow as the economy continues to grow.

What are the salary expectations for an Industrial Multicraft Maintenance Technician?

The salary expectations for an Industrial Multicraft Maintenance Technician will vary depending on experience, location, and employer. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for maintenance and repair workers was $48,310 in May 2021.

What are the benefits of working as an Industrial Multicraft Maintenance Technician?

The benefits of working as an Industrial Multicraft Maintenance Technician include steady work, competitive pay, and opportunities for advancement.