Are you a seasoned Industrial Robotics Mechanic seeking a new career path? Discover our professionally built Industrial Robotics Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

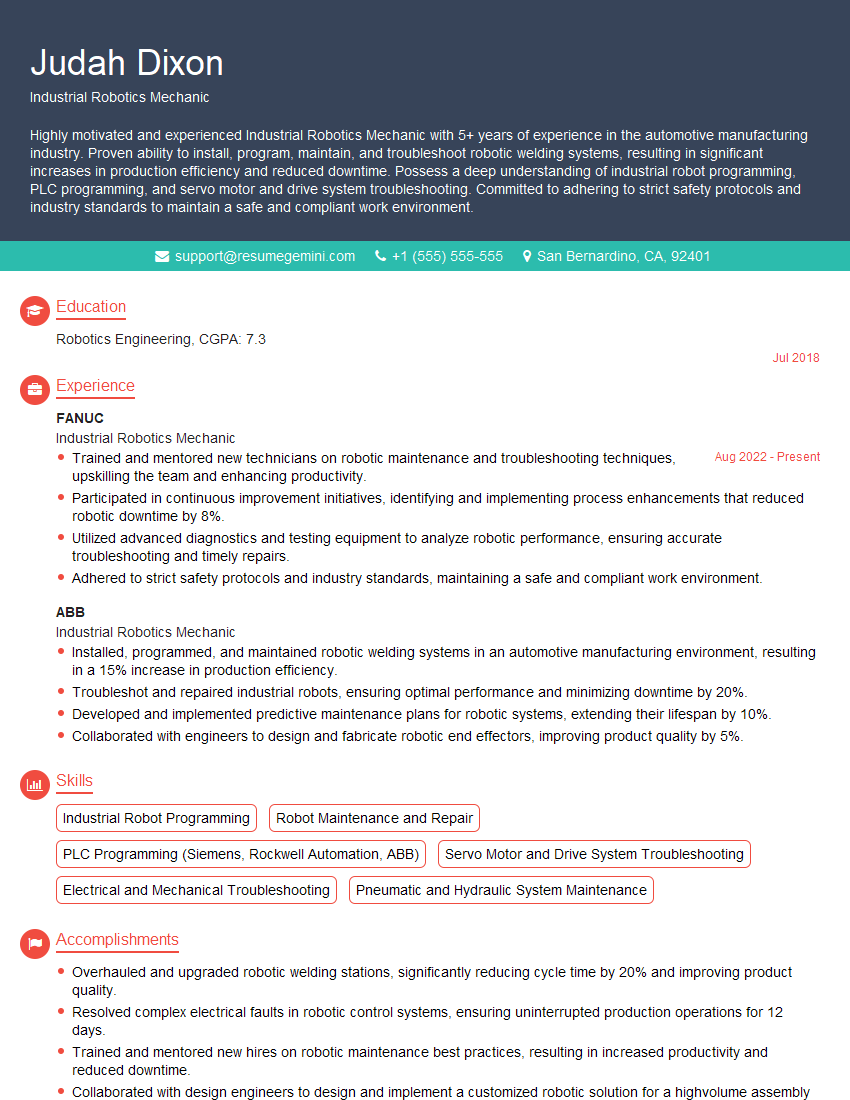

Judah Dixon

Industrial Robotics Mechanic

Summary

Highly motivated and experienced Industrial Robotics Mechanic with 5+ years of experience in the automotive manufacturing industry. Proven ability to install, program, maintain, and troubleshoot robotic welding systems, resulting in significant increases in production efficiency and reduced downtime. Possess a deep understanding of industrial robot programming, PLC programming, and servo motor and drive system troubleshooting. Committed to adhering to strict safety protocols and industry standards to maintain a safe and compliant work environment.

Education

Robotics Engineering

July 2018

Skills

- Industrial Robot Programming

- Robot Maintenance and Repair

- PLC Programming (Siemens, Rockwell Automation, ABB)

- Servo Motor and Drive System Troubleshooting

- Electrical and Mechanical Troubleshooting

- Pneumatic and Hydraulic System Maintenance

Work Experience

Industrial Robotics Mechanic

- Trained and mentored new technicians on robotic maintenance and troubleshooting techniques, upskilling the team and enhancing productivity.

- Participated in continuous improvement initiatives, identifying and implementing process enhancements that reduced robotic downtime by 8%.

- Utilized advanced diagnostics and testing equipment to analyze robotic performance, ensuring accurate troubleshooting and timely repairs.

- Adhered to strict safety protocols and industry standards, maintaining a safe and compliant work environment.

Industrial Robotics Mechanic

- Installed, programmed, and maintained robotic welding systems in an automotive manufacturing environment, resulting in a 15% increase in production efficiency.

- Troubleshot and repaired industrial robots, ensuring optimal performance and minimizing downtime by 20%.

- Developed and implemented predictive maintenance plans for robotic systems, extending their lifespan by 10%.

- Collaborated with engineers to design and fabricate robotic end effectors, improving product quality by 5%.

Accomplishments

- Overhauled and upgraded robotic welding stations, significantly reducing cycle time by 20% and improving product quality.

- Resolved complex electrical faults in robotic control systems, ensuring uninterrupted production operations for 12 days.

- Trained and mentored new hires on robotic maintenance best practices, resulting in increased productivity and reduced downtime.

- Collaborated with design engineers to design and implement a customized robotic solution for a highvolume assembly process.

- Developed preventative maintenance schedules for robotic systems, minimizing unscheduled downtime by 15%.

Awards

- Recognized with the Outstanding Achievement Award for exceptional performance in robotic system maintenance and repair.

- Recipient of the Technical Excellence Award for innovative solutions implemented to optimize robotic operations.

- Certified by the Robotic Industries Association (RIA) as an Industrial Robotics Mechanic, demonstrating advanced proficiency.

- Received the Employee of the Month award for consistently exceeding expectations in robotic maintenance and repair.

Certificates

- Certified Industrial Robot Mechanic (CIRM)

- Robotics Certification from RobotWorx or ATI

- Siemens Certified Service Engineer for Robotics

- Rockwell Automation Certified Maintenance Professional (CRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Robotics Mechanic

- Highlight your skills and experience in industrial robot programming, PLC programming, and servo motor and drive system troubleshooting.

- Showcase your ability to work independently and as part of a team to troubleshoot and resolve complex robotic issues.

- Quantify your accomplishments with specific metrics, such as the increase in production efficiency or the reduction in downtime that you achieved.

- Include keywords throughout your resume, such as ‘industrial robot programming’, ‘PLC programming’, and ‘servo motor troubleshooting’.

Essential Experience Highlights for a Strong Industrial Robotics Mechanic Resume

- Installed, programmed, and maintained robotic welding systems in an automotive manufacturing environment, resulting in a 15% increase in production efficiency.

- Troubleshot and repaired industrial robots, ensuring optimal performance and minimizing downtime by 20%.

- Collaborated with engineers to design and fabricate robotic end effectors, improving product quality by 5%.

- Developed and implemented predictive maintenance plans for robotic systems, extending their lifespan by 10%.

- Trained and mentored new technicians on robotic maintenance and troubleshooting techniques, upskilling the team and enhancing productivity.

- Utilized advanced diagnostics and testing equipment to analyze robotic performance, ensuring accurate troubleshooting and timely repairs.

Frequently Asked Questions (FAQ’s) For Industrial Robotics Mechanic

What are the key skills required for an Industrial Robotics Mechanic?

The key skills required for an Industrial Robotics Mechanic include industrial robot programming, PLC programming, servo motor and drive system troubleshooting, electrical and mechanical troubleshooting, and pneumatic and hydraulic system maintenance.

What are the primary responsibilities of an Industrial Robotics Mechanic?

The primary responsibilities of an Industrial Robotics Mechanic include installing, programming, maintaining, and troubleshooting robotic systems, as well as collaborating with engineers to design and fabricate robotic end effectors.

What are the educational requirements for an Industrial Robotics Mechanic?

Most Industrial Robotics Mechanics have a degree in Robotics Engineering or a related field.

What are the career prospects for an Industrial Robotics Mechanic?

The career prospects for an Industrial Robotics Mechanic are excellent, with a growing demand for qualified professionals in the manufacturing, automotive, and other industries.

What are the salary expectations for an Industrial Robotics Mechanic?

The salary expectations for an Industrial Robotics Mechanic vary depending on experience, qualifications, and location, but generally fall within the range of $50,000 to $100,000 per year.

What are the safety considerations for an Industrial Robotics Mechanic?

Industrial Robotics Mechanics must adhere to strict safety protocols and industry standards to maintain a safe and compliant work environment.