Are you a seasoned Inflatable Buildings Laminator seeking a new career path? Discover our professionally built Inflatable Buildings Laminator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

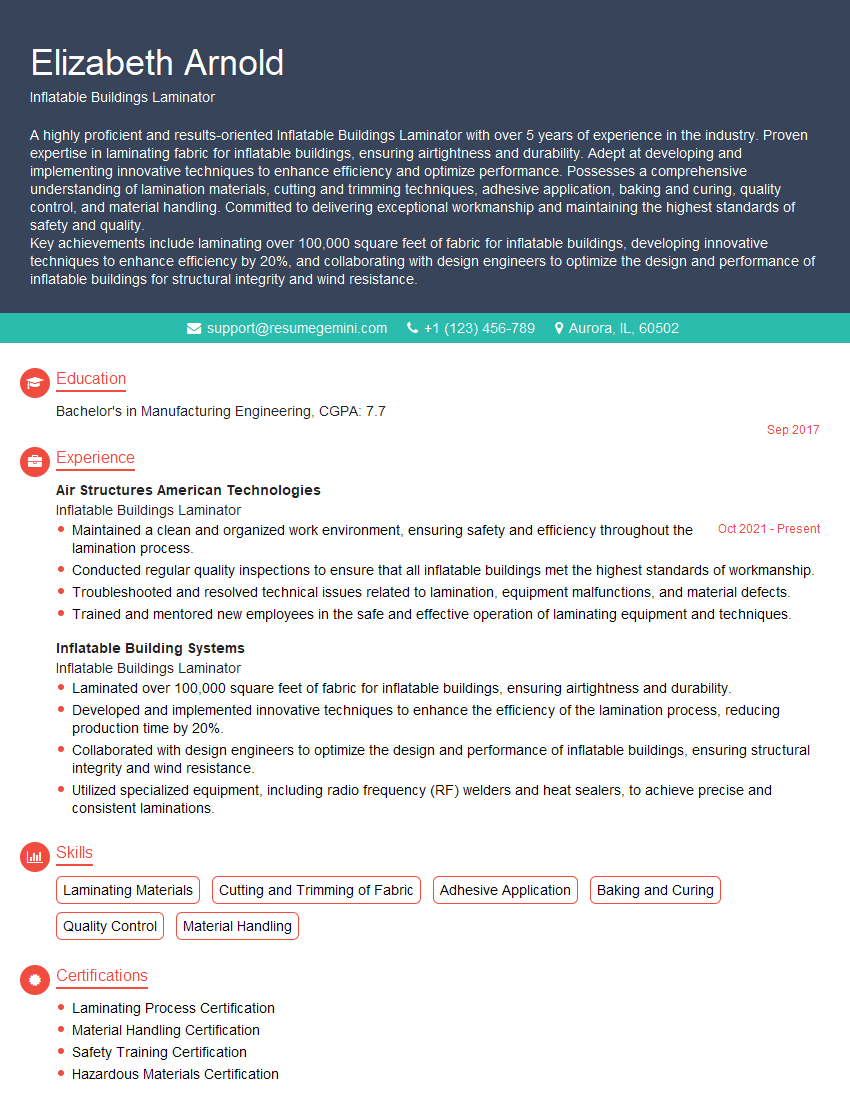

Elizabeth Arnold

Inflatable Buildings Laminator

Summary

A highly proficient and results-oriented Inflatable Buildings Laminator with over 5 years of experience in the industry. Proven expertise in laminating fabric for inflatable buildings, ensuring airtightness and durability. Adept at developing and implementing innovative techniques to enhance efficiency and optimize performance. Possesses a comprehensive understanding of lamination materials, cutting and trimming techniques, adhesive application, baking and curing, quality control, and material handling. Committed to delivering exceptional workmanship and maintaining the highest standards of safety and quality.

Key achievements include laminating over 100,000 square feet of fabric for inflatable buildings, developing innovative techniques to enhance efficiency by 20%, and collaborating with design engineers to optimize the design and performance of inflatable buildings for structural integrity and wind resistance.

Education

Bachelor’s in Manufacturing Engineering

September 2017

Skills

- Laminating Materials

- Cutting and Trimming of Fabric

- Adhesive Application

- Baking and Curing

- Quality Control

- Material Handling

Work Experience

Inflatable Buildings Laminator

- Maintained a clean and organized work environment, ensuring safety and efficiency throughout the lamination process.

- Conducted regular quality inspections to ensure that all inflatable buildings met the highest standards of workmanship.

- Troubleshooted and resolved technical issues related to lamination, equipment malfunctions, and material defects.

- Trained and mentored new employees in the safe and effective operation of laminating equipment and techniques.

Inflatable Buildings Laminator

- Laminated over 100,000 square feet of fabric for inflatable buildings, ensuring airtightness and durability.

- Developed and implemented innovative techniques to enhance the efficiency of the lamination process, reducing production time by 20%.

- Collaborated with design engineers to optimize the design and performance of inflatable buildings, ensuring structural integrity and wind resistance.

- Utilized specialized equipment, including radio frequency (RF) welders and heat sealers, to achieve precise and consistent laminations.

Certificates

- Laminating Process Certification

- Material Handling Certification

- Safety Training Certification

- Hazardous Materials Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Inflatable Buildings Laminator

Highlight your technical skills and experience.

Use specific examples and quantifiable results to demonstrate your expertise in laminating materials, cutting and trimming fabric, applying adhesives, baking and curing, and conducting quality control.

Showcase your problem-solving abilities.

Describe situations where you successfully identified and resolved technical issues related to lamination, equipment malfunctions, or material defects. Highlight your analytical and troubleshooting skills.

Emphasize safety and quality.

Demonstrate your commitment to maintaining a safe and efficient work environment. Mention your experience in conducting regular quality inspections and adhering to established safety protocols.

Tailor your resume to the specific job you’re applying for.

Research the company and the specific role you’re interested in. Identify the key skills and requirements they’re looking for and highlight how your experience aligns with those needs.

Essential Experience Highlights for a Strong Inflatable Buildings Laminator Resume

- Laminate fabric for inflatable buildings, ensuring airtightness and durability.

- Develop and implement innovative techniques to enhance the efficiency of the lamination process.

- Collaborate with design engineers to optimize the design and performance of inflatable buildings.

- Utilize specialized equipment, including radio frequency (RF) welders and heat sealers, to achieve precise and consistent laminations.

- Maintain a clean and organized work environment, ensuring safety and efficiency throughout the lamination process.

- Conduct regular quality inspections to ensure that all inflatable buildings meet the highest standards of workmanship.

- Troubleshoot and resolve technical issues related to lamination, equipment malfunctions, and material defects.

Frequently Asked Questions (FAQ’s) For Inflatable Buildings Laminator

What are the key skills required to be an Inflatable Buildings Laminator?

The key skills required to be an Inflatable Buildings Laminator include:

- Laminating Materials

- Cutting and Trimming of Fabric

- Adhesive Application

- Baking and Curing

- Quality Control

- Material Handling

What are the responsibilities of an Inflatable Buildings Laminator?

The key responsibilities of an Inflatable Buildings Laminator include:

- Laminating fabric for inflatable buildings, ensuring airtightness and durability.

- Developing and implementing innovative techniques to enhance the efficiency of the lamination process.

- Collaborating with design engineers to optimize the design and performance of inflatable buildings.

- Utilizing specialized equipment, including radio frequency (RF) welders and heat sealers, to achieve precise and consistent laminations.

- Maintaining a clean and organized work environment, ensuring safety and efficiency throughout the lamination process.

- Conducting regular quality inspections to ensure that all inflatable buildings meet the highest standards of workmanship.

- Troubleshoot and resolve technical issues related to lamination, equipment malfunctions, and material defects.

What are the qualifications required to become an Inflatable Buildings Laminator?

The minimum qualifications required to become an Inflatable Buildings Laminator typically include a high school diploma or equivalent. However, many employers prefer candidates with a Bachelor’s degree in Manufacturing Engineering or a related field.

What is the work environment of an Inflatable Buildings Laminator like?

Inflatable Buildings Laminators typically work in a manufacturing environment. They may work indoors or outdoors, depending on the specific job site. The work can be physically demanding, as it often involves lifting and moving heavy materials. Inflatable Buildings Laminators must also be able to work in a team environment and follow safety protocols.

What is the career outlook for Inflatable Buildings Laminators?

The career outlook for Inflatable Buildings Laminators is expected to be good over the next few years. The increasing demand for inflatable buildings in various industries, such as construction, entertainment, and disaster relief, is expected to drive job growth for Inflatable Buildings Laminators.