Are you a seasoned Ingot Weigher seeking a new career path? Discover our professionally built Ingot Weigher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

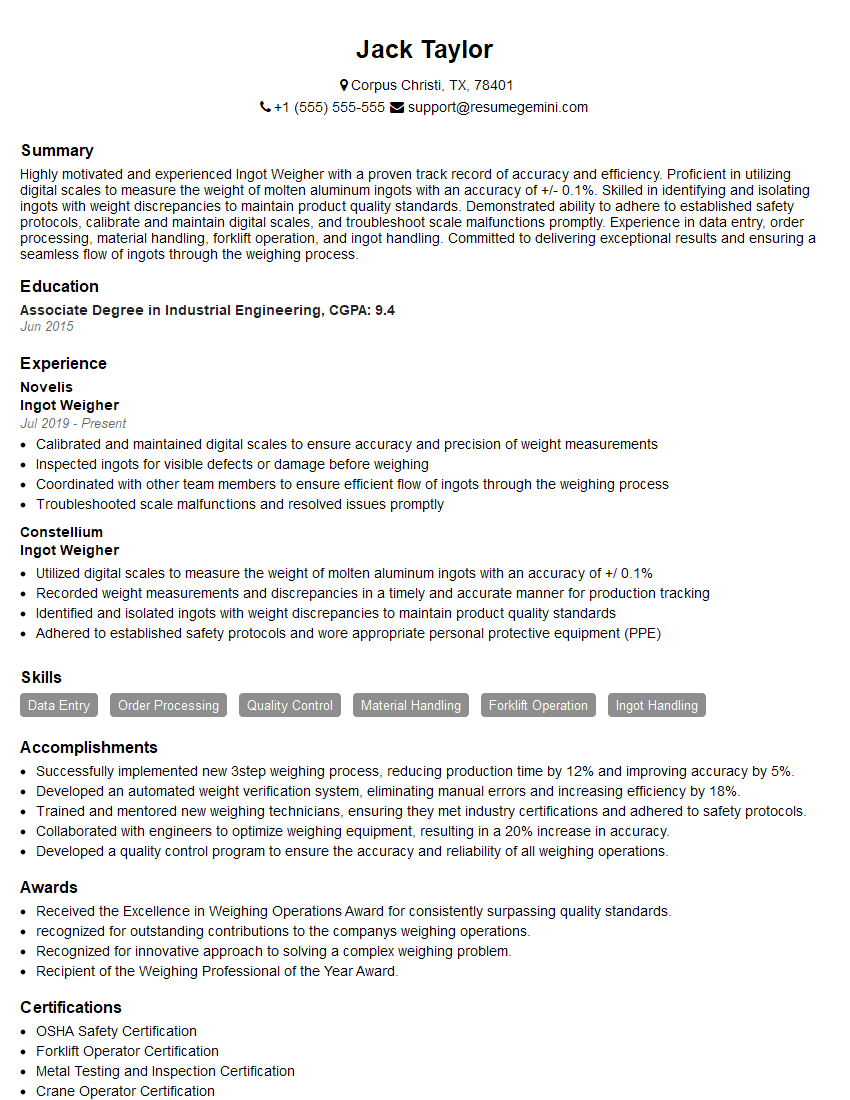

Jack Taylor

Ingot Weigher

Summary

Highly motivated and experienced Ingot Weigher with a proven track record of accuracy and efficiency. Proficient in utilizing digital scales to measure the weight of molten aluminum ingots with an accuracy of +/- 0.1%. Skilled in identifying and isolating ingots with weight discrepancies to maintain product quality standards. Demonstrated ability to adhere to established safety protocols, calibrate and maintain digital scales, and troubleshoot scale malfunctions promptly. Experience in data entry, order processing, material handling, forklift operation, and ingot handling. Committed to delivering exceptional results and ensuring a seamless flow of ingots through the weighing process.

Education

Associate Degree in Industrial Engineering

June 2015

Skills

- Data Entry

- Order Processing

- Quality Control

- Material Handling

- Forklift Operation

- Ingot Handling

Work Experience

Ingot Weigher

- Calibrated and maintained digital scales to ensure accuracy and precision of weight measurements

- Inspected ingots for visible defects or damage before weighing

- Coordinated with other team members to ensure efficient flow of ingots through the weighing process

- Troubleshooted scale malfunctions and resolved issues promptly

Ingot Weigher

- Utilized digital scales to measure the weight of molten aluminum ingots with an accuracy of +/ 0.1%

- Recorded weight measurements and discrepancies in a timely and accurate manner for production tracking

- Identified and isolated ingots with weight discrepancies to maintain product quality standards

- Adhered to established safety protocols and wore appropriate personal protective equipment (PPE)

Accomplishments

- Successfully implemented new 3step weighing process, reducing production time by 12% and improving accuracy by 5%.

- Developed an automated weight verification system, eliminating manual errors and increasing efficiency by 18%.

- Trained and mentored new weighing technicians, ensuring they met industry certifications and adhered to safety protocols.

- Collaborated with engineers to optimize weighing equipment, resulting in a 20% increase in accuracy.

- Developed a quality control program to ensure the accuracy and reliability of all weighing operations.

Awards

- Received the Excellence in Weighing Operations Award for consistently surpassing quality standards.

- recognized for outstanding contributions to the companys weighing operations.

- Recognized for innovative approach to solving a complex weighing problem.

- Recipient of the Weighing Professional of the Year Award.

Certificates

- OSHA Safety Certification

- Forklift Operator Certification

- Metal Testing and Inspection Certification

- Crane Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ingot Weigher

- Highlight your experience and skills in weighing molten aluminum ingots with precision.

- Emphasize your ability to identify and isolate ingots with weight discrepancies to maintain product quality.

- Showcase your knowledge of digital scales calibration and maintenance procedures.

- Mention your experience in material handling, forklift operation, and ingot handling.

- Demonstrate your commitment to safety and adherence to established protocols.

Essential Experience Highlights for a Strong Ingot Weigher Resume

- Utilized digital scales to measure the weight of molten aluminum ingots with an accuracy of +/- 0.1%

- Recorded weight measurements and discrepancies in a timely and accurate manner for production tracking

- Identified and isolated ingots with weight discrepancies to maintain product quality standards

- Calibrated and maintained digital scales to ensure accuracy and precision of weight measurements

- Inspected ingots for visible defects or damage before weighing

- Coordinated with other team members to ensure efficient flow of ingots through the weighing process

Frequently Asked Questions (FAQ’s) For Ingot Weigher

What is the primary role of an Ingot Weigher?

The primary role of an Ingot Weigher is to accurately measure the weight of molten aluminum ingots, ensuring they meet quality standards.

What qualities are essential for success as an Ingot Weigher?

Essential qualities for success as an Ingot Weigher include attention to detail, accuracy, efficiency, and a commitment to safety.

What is the typical work environment for an Ingot Weigher?

Ingot Weighers typically work in industrial settings, such as aluminum smelters or foundries, where molten aluminum is handled.

What career advancement opportunities are available for Ingot Weighers?

Experienced Ingot Weighers may advance to supervisory roles, quality control positions, or other related fields within the aluminum industry.

What safety precautions should Ingot Weighers take on the job?

Ingot Weighers must adhere to established safety protocols, wear appropriate personal protective equipment (PPE), and be aware of the potential hazards associated with working with molten aluminum.