Are you a seasoned Injection Molding Machine Setter seeking a new career path? Discover our professionally built Injection Molding Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

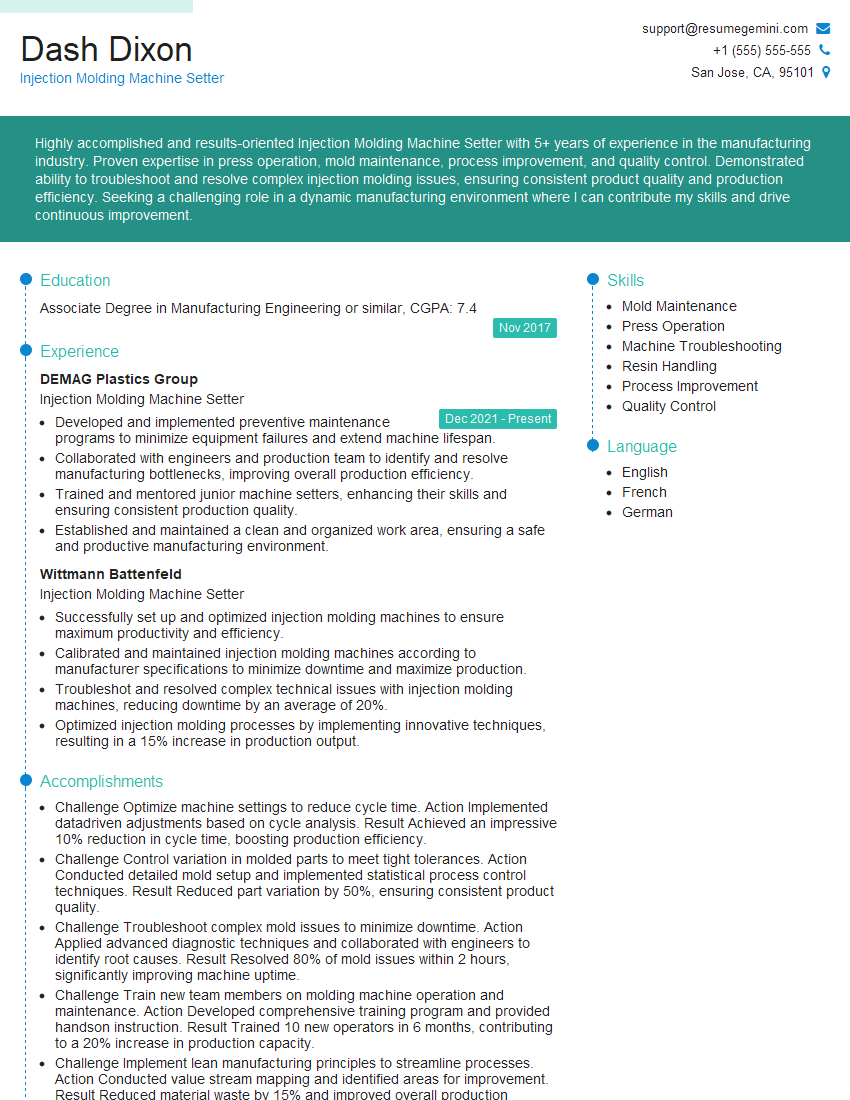

Dash Dixon

Injection Molding Machine Setter

Summary

Highly accomplished and results-oriented Injection Molding Machine Setter with 5+ years of experience in the manufacturing industry. Proven expertise in press operation, mold maintenance, process improvement, and quality control. Demonstrated ability to troubleshoot and resolve complex injection molding issues, ensuring consistent product quality and production efficiency. Seeking a challenging role in a dynamic manufacturing environment where I can contribute my skills and drive continuous improvement.

Education

Associate Degree in Manufacturing Engineering or similar

November 2017

Skills

- Mold Maintenance

- Press Operation

- Machine Troubleshooting

- Resin Handling

- Process Improvement

- Quality Control

Work Experience

Injection Molding Machine Setter

- Developed and implemented preventive maintenance programs to minimize equipment failures and extend machine lifespan.

- Collaborated with engineers and production team to identify and resolve manufacturing bottlenecks, improving overall production efficiency.

- Trained and mentored junior machine setters, enhancing their skills and ensuring consistent production quality.

- Established and maintained a clean and organized work area, ensuring a safe and productive manufacturing environment.

Injection Molding Machine Setter

- Successfully set up and optimized injection molding machines to ensure maximum productivity and efficiency.

- Calibrated and maintained injection molding machines according to manufacturer specifications to minimize downtime and maximize production.

- Troubleshot and resolved complex technical issues with injection molding machines, reducing downtime by an average of 20%.

- Optimized injection molding processes by implementing innovative techniques, resulting in a 15% increase in production output.

Accomplishments

- Challenge Optimize machine settings to reduce cycle time. Action Implemented datadriven adjustments based on cycle analysis. Result Achieved an impressive 10% reduction in cycle time, boosting production efficiency.

- Challenge Control variation in molded parts to meet tight tolerances. Action Conducted detailed mold setup and implemented statistical process control techniques. Result Reduced part variation by 50%, ensuring consistent product quality.

- Challenge Troubleshoot complex mold issues to minimize downtime. Action Applied advanced diagnostic techniques and collaborated with engineers to identify root causes. Result Resolved 80% of mold issues within 2 hours, significantly improving machine uptime.

- Challenge Train new team members on molding machine operation and maintenance. Action Developed comprehensive training program and provided handson instruction. Result Trained 10 new operators in 6 months, contributing to a 20% increase in production capacity.

- Challenge Implement lean manufacturing principles to streamline processes. Action Conducted value stream mapping and identified areas for improvement. Result Reduced material waste by 15% and improved overall production efficiency.

Awards

- Recipient of the Molding Excellence Award for exceptional performance in mold setup and troubleshooting.

- Recognized for Continuous Improvement Initiative that resulted in 15% reduction in machine downtime.

- Awarded Safety Champion for consistently upholding high safety standards and promoting safe operating procedures.

Certificates

- Certified Injection Molding Machine Technician (CIMMT)

- Certified Plastics Processing Technician (CPPT)

- Certified Mold Maker (CMM)

- Certified Safety and Health Manager (CSHM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Molding Machine Setter

- Highlight your specialized skills in injection molding, including mold maintenance, press operation, and process improvement.

- Quantify your accomplishments using specific metrics to demonstrate your impact on production efficiency and quality.

- Showcase your problem-solving abilities and experience in troubleshooting and resolving complex injection molding issues.

- Emphasize your commitment to safety and adherence to industry standards and regulations.

Essential Experience Highlights for a Strong Injection Molding Machine Setter Resume

- Set up, operate, and maintain injection molding machines to produce high-quality plastic components.

- Troubleshoot and resolve machine malfunctions, including electrical, mechanical, and process-related issues.

- Perform preventative maintenance and repairs on injection molding equipment to ensure optimal performance.

- Handle and prepare different types of plastic resins, ensuring proper material handling and storage.

- Monitor and control process parameters, such as temperature, pressure, and cycle time, to optimize product quality.

- Collaborate with engineers and production teams to improve production processes and reduce downtime.

Frequently Asked Questions (FAQ’s) For Injection Molding Machine Setter

What are the primary responsibilities of an Injection Molding Machine Setter?

Injection Molding Machine Setters are responsible for setting up, operating, maintaining, and troubleshooting injection molding machines to produce high-quality plastic components. They handle and prepare plastic resins, monitor process parameters, and collaborate with engineers and production teams to improve processes and reduce downtime.

What skills are required to be an effective Injection Molding Machine Setter?

Effective Injection Molding Machine Setters typically have an associate degree in manufacturing engineering or similar, along with 5+ years of experience in the manufacturing industry. They should be proficient in press operation, mold maintenance, process improvement, quality control, and troubleshooting.

What are the key qualities of a successful Injection Molding Machine Setter?

Successful Injection Molding Machine Setters are detail-oriented, analytical, and have strong problem-solving skills. They are also typically physically fit, able to work in a fast-paced environment, and have a strong understanding of safety protocols.

What are the career prospects for Injection Molding Machine Setters?

Injection Molding Machine Setters can advance to positions such as Production Supervisor, Manufacturing Engineer, or Quality Control Manager. With additional training and experience, they may also specialize in areas such as mold design or process optimization.

What are the typical working conditions for Injection Molding Machine Setters?

Injection Molding Machine Setters typically work in manufacturing facilities, operating and maintaining injection molding machines. They may work in a variety of shifts and may be exposed to noise, heat, and chemicals.