Are you a seasoned Injection Molding Process Technician seeking a new career path? Discover our professionally built Injection Molding Process Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

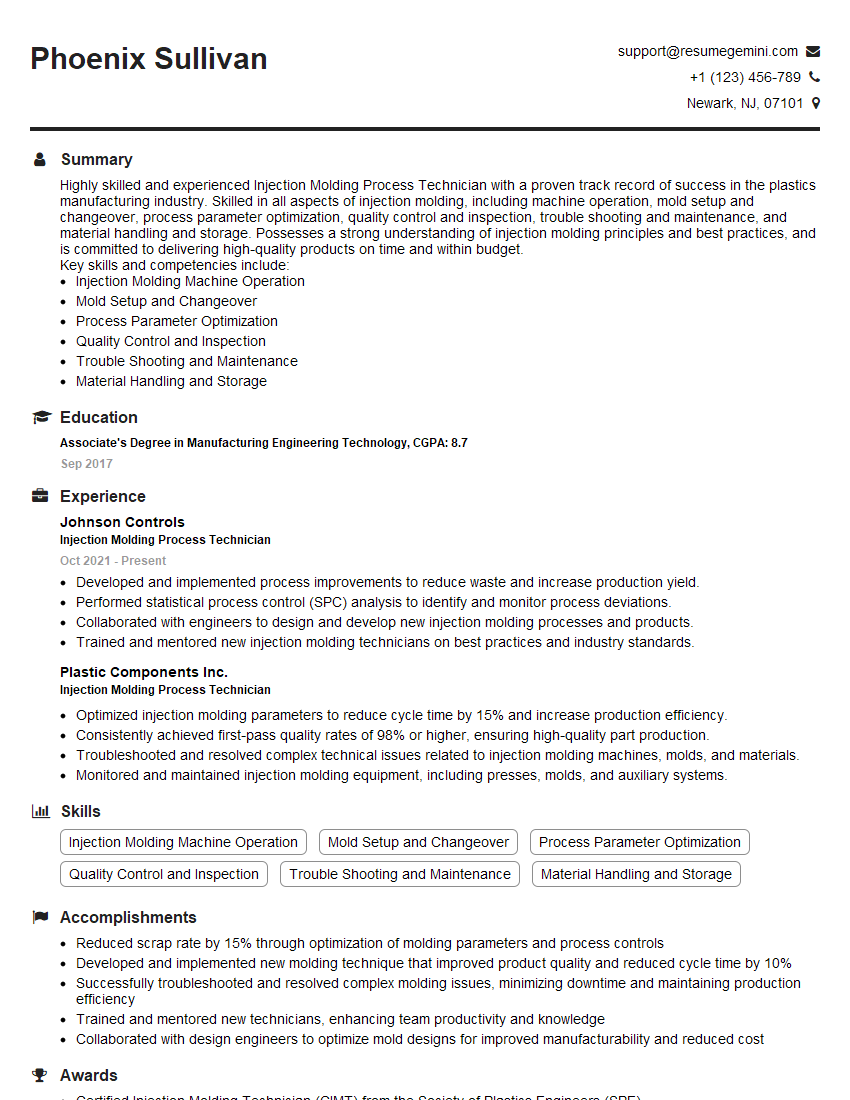

Phoenix Sullivan

Injection Molding Process Technician

Summary

Highly skilled and experienced Injection Molding Process Technician with a proven track record of success in the plastics manufacturing industry. Skilled in all aspects of injection molding, including machine operation, mold setup and changeover, process parameter optimization, quality control and inspection, trouble shooting and maintenance, and material handling and storage. Possesses a strong understanding of injection molding principles and best practices, and is committed to delivering high-quality products on time and within budget.

Key skills and competencies include:

- Injection Molding Machine Operation

- Mold Setup and Changeover

- Process Parameter Optimization

- Quality Control and Inspection

- Trouble Shooting and Maintenance

- Material Handling and Storage

Education

Associate’s Degree in Manufacturing Engineering Technology

September 2017

Skills

- Injection Molding Machine Operation

- Mold Setup and Changeover

- Process Parameter Optimization

- Quality Control and Inspection

- Trouble Shooting and Maintenance

- Material Handling and Storage

Work Experience

Injection Molding Process Technician

- Developed and implemented process improvements to reduce waste and increase production yield.

- Performed statistical process control (SPC) analysis to identify and monitor process deviations.

- Collaborated with engineers to design and develop new injection molding processes and products.

- Trained and mentored new injection molding technicians on best practices and industry standards.

Injection Molding Process Technician

- Optimized injection molding parameters to reduce cycle time by 15% and increase production efficiency.

- Consistently achieved first-pass quality rates of 98% or higher, ensuring high-quality part production.

- Troubleshooted and resolved complex technical issues related to injection molding machines, molds, and materials.

- Monitored and maintained injection molding equipment, including presses, molds, and auxiliary systems.

Accomplishments

- Reduced scrap rate by 15% through optimization of molding parameters and process controls

- Developed and implemented new molding technique that improved product quality and reduced cycle time by 10%

- Successfully troubleshooted and resolved complex molding issues, minimizing downtime and maintaining production efficiency

- Trained and mentored new technicians, enhancing team productivity and knowledge

- Collaborated with design engineers to optimize mold designs for improved manufacturability and reduced cost

Awards

- Certified Injection Molding Technician (CIMT) from the Society of Plastics Engineers (SPE)

- Award of Excellence in Injection Molding from the American Society for Testing and Materials (ASTM)

- Recognition for outstanding performance in injection molding from the companys management

Certificates

- Certified Injection Molding Technician (CIMT)

- Certified Molding Technician (CMT)

- Certified Process Technician (CPT)

- Certified Plastics Processor (CPP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Molding Process Technician

- Highlight your specific skills and experience in injection molding, including your knowledge of different types of machines, materials, and processes.

- Quantify your accomplishments whenever possible, providing specific examples of how you have improved efficiency, reduced costs, or enhanced product quality.

- Showcase your troubleshooting and problem-solving abilities, emphasizing your ability to quickly identify and resolve issues that arise during the injection molding process.

- Demonstrate your commitment to continuous learning and professional development, including any relevant certifications or training programs you have completed.

Essential Experience Highlights for a Strong Injection Molding Process Technician Resume

- Operate and maintain injection molding machines to produce plastic parts and components.

- Set up and changeover molds, ensuring proper alignment and operation.

- Optimize process parameters such as temperature, pressure, and cycle time to achieve desired product quality and efficiency.

- Conduct quality control inspections to ensure that parts meet specifications.

- Troubleshoot and resolve equipment malfunctions, minimizing downtime and ensuring efficient production.

- Maintain a clean and organized work area, following safety protocols and best practices.

- Collaborate with engineers and other team members to improve processes and resolve technical issues.

Frequently Asked Questions (FAQ’s) For Injection Molding Process Technician

What are the primary responsibilities of an Injection Molding Process Technician?

Injection Molding Process Technicians are responsible for operating and maintaining injection molding machines, setting up and changing molds, optimizing process parameters, conducting quality control inspections, troubleshooting and resolving equipment malfunctions, and maintaining a clean and organized work area.

What are the key skills and qualifications required for this role?

Key skills and qualifications for an Injection Molding Process Technician include a strong understanding of injection molding principles and best practices, experience in operating and maintaining injection molding machines, proficiency in mold setup and changeover, expertise in process parameter optimization, and a commitment to delivering high-quality products.

What are the career prospects for Injection Molding Process Technicians?

Injection Molding Process Technicians with experience and expertise can advance to roles such as Injection Molding Supervisor, Manufacturing Engineer, or Quality Control Manager. They may also specialize in specific areas of injection molding, such as mold design or process optimization.

What is the work environment like for Injection Molding Process Technicians?

Injection Molding Process Technicians typically work in manufacturing facilities, operating and maintaining injection molding machines in a production environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What are the safety considerations for Injection Molding Process Technicians?

Injection Molding Process Technicians must follow strict safety protocols to minimize the risk of injury. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs, and being aware of potential hazards such as hot surfaces, moving machinery, and molten plastic.

What are the major industries that employ Injection Molding Process Technicians?

Injection Molding Process Technicians are employed in a variety of industries that utilize plastic components, including automotive, electronics,????, packaging, and consumer products.

What is the average salary for Injection Molding Process Technicians?

The average salary for Injection Molding Process Technicians varies depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Plastic Molding Machine Operators and Setters, which includes Injection Molding Process Technicians, was $42,010 in May 2021.

How can I become an Injection Molding Process Technician?

To become an Injection Molding Process Technician, you can pursue an associate’s degree in manufacturing engineering technology or a related field, and gain hands-on experience through internships or entry-level positions in the plastics manufacturing industry.