Are you a seasoned Injection Molding Technician seeking a new career path? Discover our professionally built Injection Molding Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

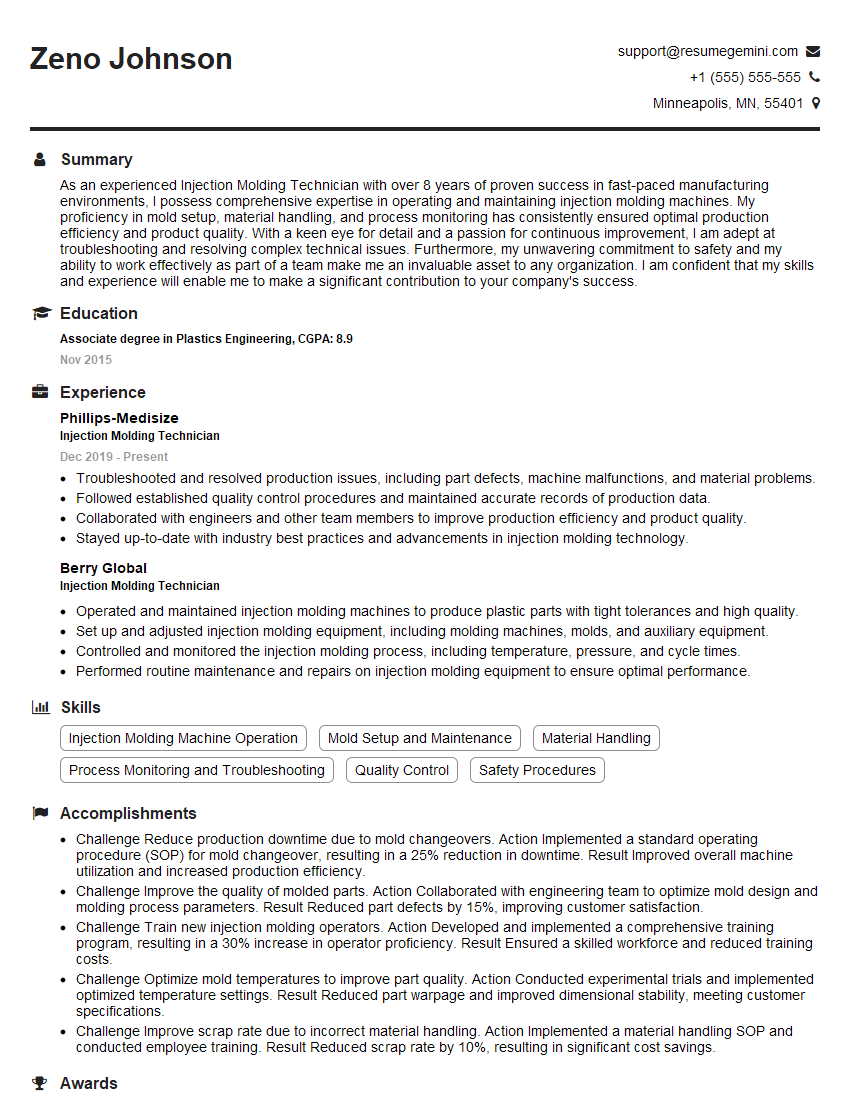

Zeno Johnson

Injection Molding Technician

Summary

As an experienced Injection Molding Technician with over 8 years of proven success in fast-paced manufacturing environments, I possess comprehensive expertise in operating and maintaining injection molding machines. My proficiency in mold setup, material handling, and process monitoring has consistently ensured optimal production efficiency and product quality. With a keen eye for detail and a passion for continuous improvement, I am adept at troubleshooting and resolving complex technical issues. Furthermore, my unwavering commitment to safety and my ability to work effectively as part of a team make me an invaluable asset to any organization. I am confident that my skills and experience will enable me to make a significant contribution to your company’s success.

Education

Associate degree in Plastics Engineering

November 2015

Skills

- Injection Molding Machine Operation

- Mold Setup and Maintenance

- Material Handling

- Process Monitoring and Troubleshooting

- Quality Control

- Safety Procedures

Work Experience

Injection Molding Technician

- Troubleshooted and resolved production issues, including part defects, machine malfunctions, and material problems.

- Followed established quality control procedures and maintained accurate records of production data.

- Collaborated with engineers and other team members to improve production efficiency and product quality.

- Stayed up-to-date with industry best practices and advancements in injection molding technology.

Injection Molding Technician

- Operated and maintained injection molding machines to produce plastic parts with tight tolerances and high quality.

- Set up and adjusted injection molding equipment, including molding machines, molds, and auxiliary equipment.

- Controlled and monitored the injection molding process, including temperature, pressure, and cycle times.

- Performed routine maintenance and repairs on injection molding equipment to ensure optimal performance.

Accomplishments

- Challenge Reduce production downtime due to mold changeovers. Action Implemented a standard operating procedure (SOP) for mold changeover, resulting in a 25% reduction in downtime. Result Improved overall machine utilization and increased production efficiency.

- Challenge Improve the quality of molded parts. Action Collaborated with engineering team to optimize mold design and molding process parameters. Result Reduced part defects by 15%, improving customer satisfaction.

- Challenge Train new injection molding operators. Action Developed and implemented a comprehensive training program, resulting in a 30% increase in operator proficiency. Result Ensured a skilled workforce and reduced training costs.

- Challenge Optimize mold temperatures to improve part quality. Action Conducted experimental trials and implemented optimized temperature settings. Result Reduced part warpage and improved dimensional stability, meeting customer specifications.

- Challenge Improve scrap rate due to incorrect material handling. Action Implemented a material handling SOP and conducted employee training. Result Reduced scrap rate by 10%, resulting in significant cost savings.

Awards

- Received the Injection Molding Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Recognized as Technician of the Month for exceptional troubleshooting skills and resolving complex machine issues efficiently.

- Awarded the Safety Excellence Award for adhering to strict safety regulations and maintaining a safe work environment.

- Recognized for Excellence in Innovation for developing a new mold design that reduced cycle time by 10%.

Certificates

- Certified Injection Molding Technician (CIMT)

- SPI Certified Injection Molding Technician

- ISO 9001:2015 Quality Management System Certification

- OSHA 10-Hour Safety Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Molding Technician

Highlight your technical skills.

Injection molding technicians need to have a strong understanding of the machinery and processes involved in injection molding. Make sure to list your experience with specific types of machines and materials, as well as your knowledge of mold design and maintenance.Quantify your accomplishments.

Whenever possible, use numbers to demonstrate your impact on production. For example, you could mention the number of parts you produced per hour or the percentage of products you inspected that met quality standards.Tailor your resume to the job description.

Take the time to read the job description carefully and identify the skills and experience that the employer is looking for. Then, make sure to highlight those skills and experience in your resume.Proofread carefully.

A well-written resume is free of errors. Make sure to proofread your resume carefully before you submit it.

Essential Experience Highlights for a Strong Injection Molding Technician Resume

- Operate injection molding machines to produce plastic parts according to specifications.

- Set up and maintain molds, including changing inserts and adjusting settings.

- Handle and prepare raw materials, ensuring proper storage and usage.

- Monitor production processes, identifying and resolving any issues that arise.

- Conduct quality control inspections to ensure products meet specifications.

- Adhere to established safety protocols, ensuring a hazard-free work environment.

- Work collaboratively with team members to optimize production and resolve challenges.

Frequently Asked Questions (FAQ’s) For Injection Molding Technician

What is injection molding?

Injection molding is a manufacturing process for producing parts by injecting molten plastic into a mold. The mold is made of two halves that are held together by a clamping force. The molten plastic is injected into the mold under high pressure, and the mold is cooled to solidify the plastic. Once the plastic is solidified, the mold is opened and the part is ejected.

What are the different types of injection molding machines?

There are several different types of injection molding machines, including vertical, horizontal, and rotary. Each type of machine has its own advantages and disadvantages, and the best type of machine for a particular application will depend on the part being produced.

What are the different types of molds used in injection molding?

There are several different types of molds used in injection molding, including two-plate molds, three-plate molds, and hot runner molds. Each type of mold has its own advantages and disadvantages, and the best type of mold for a particular application will depend on the part being produced.

What are the different types of plastic materials used in injection molding?

There are several different types of plastic materials used in injection molding, including polyethylene, polypropylene, and polystyrene. Each type of plastic has its own unique properties, and the best type of plastic for a particular application will depend on the part being produced.

What are the different applications for injection molded parts?

Injection molded parts are used in a wide variety of applications, including automotive, consumer products, and medical devices. Injection molding is a versatile process that can be used to produce parts of all shapes and sizes.

What are the benefits of injection molding?

Injection molding offers several benefits, including high production rates, low cost, and consistent quality. Injection molding is also a versatile process that can be used to produce parts of all shapes and sizes.