Are you a seasoned Injection Press Operator seeking a new career path? Discover our professionally built Injection Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

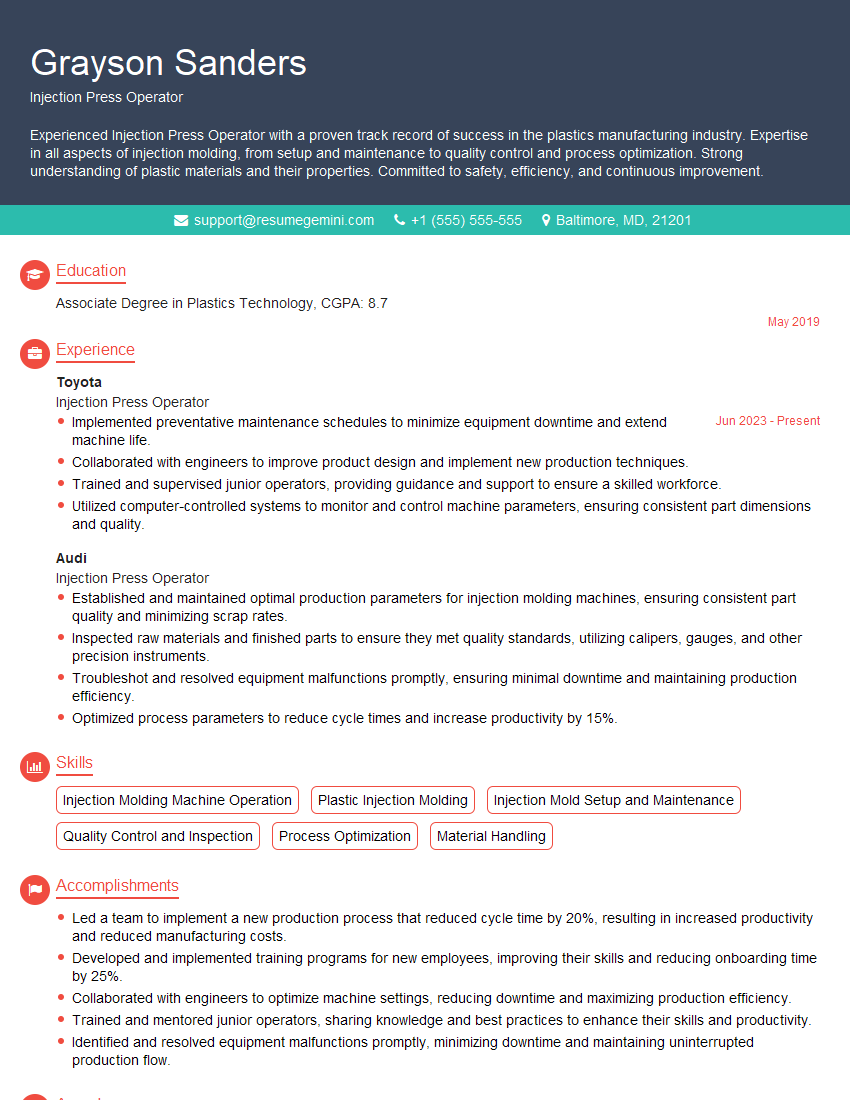

Grayson Sanders

Injection Press Operator

Summary

Experienced Injection Press Operator with a proven track record of success in the plastics manufacturing industry. Expertise in all aspects of injection molding, from setup and maintenance to quality control and process optimization. Strong understanding of plastic materials and their properties. Committed to safety, efficiency, and continuous improvement.

Education

Associate Degree in Plastics Technology

May 2019

Skills

- Injection Molding Machine Operation

- Plastic Injection Molding

- Injection Mold Setup and Maintenance

- Quality Control and Inspection

- Process Optimization

- Material Handling

Work Experience

Injection Press Operator

- Implemented preventative maintenance schedules to minimize equipment downtime and extend machine life.

- Collaborated with engineers to improve product design and implement new production techniques.

- Trained and supervised junior operators, providing guidance and support to ensure a skilled workforce.

- Utilized computer-controlled systems to monitor and control machine parameters, ensuring consistent part dimensions and quality.

Injection Press Operator

- Established and maintained optimal production parameters for injection molding machines, ensuring consistent part quality and minimizing scrap rates.

- Inspected raw materials and finished parts to ensure they met quality standards, utilizing calipers, gauges, and other precision instruments.

- Troubleshot and resolved equipment malfunctions promptly, ensuring minimal downtime and maintaining production efficiency.

- Optimized process parameters to reduce cycle times and increase productivity by 15%.

Accomplishments

- Led a team to implement a new production process that reduced cycle time by 20%, resulting in increased productivity and reduced manufacturing costs.

- Developed and implemented training programs for new employees, improving their skills and reducing onboarding time by 25%.

- Collaborated with engineers to optimize machine settings, reducing downtime and maximizing production efficiency.

- Trained and mentored junior operators, sharing knowledge and best practices to enhance their skills and productivity.

- Identified and resolved equipment malfunctions promptly, minimizing downtime and maintaining uninterrupted production flow.

Awards

- Received the Employee of the Year Award for consistently exceeding production targets and maintaining high quality standards.

- Earned recognition for achieving zero defects for six consecutive months, ensuring the highest quality of products.

- Honored with the Safety Excellence Award for implementing innovative safety measures that reduced workplace accidents by 30%.

- Recognized for outstanding teamwork and collaboration, resulting in a 15% improvement in overall team productivity.

Certificates

- Certified Injection Molding Operator (CMO)

- Certified Injection Molding Technician (CIMT)

- Certified Plastic Technician (CPT)

- Certified Mold Technician (CMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Injection Press Operator

- Highlight your technical skills and experience in injection molding.

- Demonstrate your understanding of plastic materials and their properties.

- Showcase your commitment to safety and quality control.

- Emphasize your ability to troubleshoot and resolve problems effectively.

Essential Experience Highlights for a Strong Injection Press Operator Resume

- Set up, operate, and maintain injection molding machines to produce plastic parts.

- Monitor and control process parameters to ensure product quality and consistency.

- Perform quality control inspections on finished parts to identify and correct defects.

- Troubleshoot and resolve machine and process problems to maximize uptime and efficiency.

- Maintain a clean and organized work area to comply with safety regulations.

- Collaborate with other team members to optimize production processes and improve product quality.

Frequently Asked Questions (FAQ’s) For Injection Press Operator

What is the role of an Injection Press Operator?

An Injection Press Operator is responsible for setting up, operating, and maintaining injection molding machines to produce plastic parts. They monitor and control process parameters, perform quality control inspections, and troubleshoot problems to ensure product quality and efficiency.

What are the key skills required for an Injection Press Operator?

Key skills for an Injection Press Operator include injection molding machine operation, plastic injection molding, injection mold setup and maintenance, quality control and inspection, process optimization, and material handling.

What are the career prospects for an Injection Press Operator?

Injection Press Operators with experience and expertise can advance to supervisory or management roles within the plastics manufacturing industry. They may also specialize in specific areas such as mold design, process engineering, or quality control.

What is the work environment of an Injection Press Operator?

Injection Press Operators typically work in manufacturing facilities, operating injection molding machines in a production environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What are the safety precautions that Injection Press Operators must follow?

Injection Press Operators must follow strict safety protocols to minimize the risk of accidents and injuries. These precautions include wearing appropriate safety gear, following lockout/tagout procedures, and being aware of potential hazards such as hot surfaces, moving machinery, and molten plastic.

What are the industry trends that are impacting Injection Press Operators?

The plastics manufacturing industry is constantly evolving, driven by advancements in technology and the development of new materials. Injection Press Operators need to stay up-to-date on these trends, such as the use of automation and robotics, sustainable materials, and Industry 4.0 technologies, to remain competitive in the job market.