Are you a seasoned Instrument and Controls Technician (I & C Technician) seeking a new career path? Discover our professionally built Instrument and Controls Technician (I & C Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

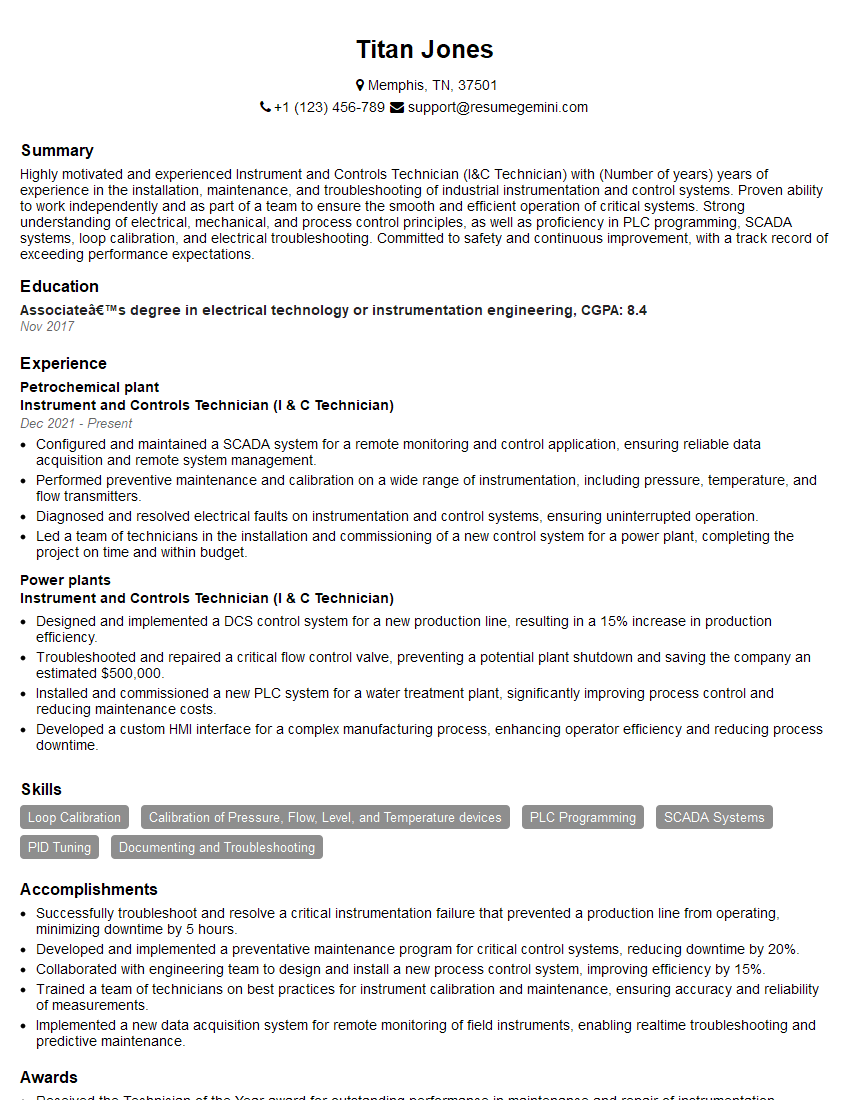

Titan Jones

Instrument and Controls Technician (I & C Technician)

Summary

Highly motivated and experienced Instrument and Controls Technician (I&C Technician) with (Number of years) years of experience in the installation, maintenance, and troubleshooting of industrial instrumentation and control systems. Proven ability to work independently and as part of a team to ensure the smooth and efficient operation of critical systems. Strong understanding of electrical, mechanical, and process control principles, as well as proficiency in PLC programming, SCADA systems, loop calibration, and electrical troubleshooting. Committed to safety and continuous improvement, with a track record of exceeding performance expectations.

Education

Associate’s degree in electrical technology or instrumentation engineering

November 2017

Skills

- Loop Calibration

- Calibration of Pressure, Flow, Level, and Temperature devices

- PLC Programming

- SCADA Systems

- PID Tuning

- Documenting and Troubleshooting

Work Experience

Instrument and Controls Technician (I & C Technician)

- Configured and maintained a SCADA system for a remote monitoring and control application, ensuring reliable data acquisition and remote system management.

- Performed preventive maintenance and calibration on a wide range of instrumentation, including pressure, temperature, and flow transmitters.

- Diagnosed and resolved electrical faults on instrumentation and control systems, ensuring uninterrupted operation.

- Led a team of technicians in the installation and commissioning of a new control system for a power plant, completing the project on time and within budget.

Instrument and Controls Technician (I & C Technician)

- Designed and implemented a DCS control system for a new production line, resulting in a 15% increase in production efficiency.

- Troubleshooted and repaired a critical flow control valve, preventing a potential plant shutdown and saving the company an estimated $500,000.

- Installed and commissioned a new PLC system for a water treatment plant, significantly improving process control and reducing maintenance costs.

- Developed a custom HMI interface for a complex manufacturing process, enhancing operator efficiency and reducing process downtime.

Accomplishments

- Successfully troubleshoot and resolve a critical instrumentation failure that prevented a production line from operating, minimizing downtime by 5 hours.

- Developed and implemented a preventative maintenance program for critical control systems, reducing downtime by 20%.

- Collaborated with engineering team to design and install a new process control system, improving efficiency by 15%.

- Trained a team of technicians on best practices for instrument calibration and maintenance, ensuring accuracy and reliability of measurements.

- Implemented a new data acquisition system for remote monitoring of field instruments, enabling realtime troubleshooting and predictive maintenance.

Awards

- Received the Technician of the Year award for outstanding performance in maintenance and repair of instrumentation systems.

- Recognized for exceptional troubleshooting skills and innovative solutions to complex instrumentation issues.

- Received industry certification as an Instrumentation and Control Technician, demonstrating expertise and commitment to professional development.

Certificates

- Certified Control System Technician (CCST)

- Industrial Automation Technician Certification (IAT)

- ISA Certified Measurement Technician (CMT)

- Certified Practicing Instrument Technician (CPIT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument and Controls Technician (I & C Technician)

- Highlight your technical skills and experience with specific instrumentation and control systems.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Tailor your resume to the specific job description and company you are applying to.

- Proofread your resume carefully for any errors before submitting it.

- Consider getting feedback from a career counselor or resume writing service to enhance your resume.

Essential Experience Highlights for a Strong Instrument and Controls Technician (I & C Technician) Resume

- Install, maintain, and troubleshoot a wide range of industrial instrumentation, including pressure, temperature, flow, and level transmitters.

- Program and configure PLC (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems to automate industrial processes.

- Perform loop calibration and tuning to ensure accuracy and stability of instrumentation and control systems.

- Troubleshoot and repair electrical faults on instrumentation and control systems, ensuring uninterrupted operation of critical systems.

- Conduct preventive maintenance and inspections to identify potential issues and minimize downtime.

- Provide technical support to operations and maintenance personnel, ensuring efficient resolution of issues.

- Stay up-to-date on industry best practices and advancements in instrumentation and control technologies.

Frequently Asked Questions (FAQ’s) For Instrument and Controls Technician (I & C Technician)

What is the role of an Instrument and Controls Technician?

An Instrument and Controls Technician (I&C Technician) is responsible for the installation, maintenance, and troubleshooting of instrumentation and control systems used in industrial settings. They ensure the accurate and reliable operation of equipment, ensuring the safety and efficiency of industrial processes.

What are the qualifications required to become an I&C Technician?

Typically, an associate’s degree in electrical technology or instrumentation engineering is required. Additional qualifications may include technical certifications, industry experience, and knowledge of specific software and equipment.

What are the key skills and responsibilities of an I&C Technician?

Key skills include proficiency in electrical and mechanical principles, PLC programming, SCADA systems, and instrumentation calibration. Responsibilities involve installing, maintaining, troubleshooting, and repairing instrumentation and control systems, as well as performing preventive maintenance and inspections.

What are the career opportunities for I&C Technicians?

I&C Technicians can work in various industries, including manufacturing, power generation, oil and gas, and pharmaceuticals. They can advance their careers by specializing in specific areas, such as automation or process control, or by pursuing management positions.

What is the job outlook for I&C Technicians?

The job outlook for I&C Technicians is expected to be positive due to the increasing demand for automation and instrumentation in various industries. The aging workforce and the need for skilled technicians also contribute to the favorable job outlook.

What are the safety considerations for I&C Technicians?

I&C Technicians work with electrical equipment and industrial machinery, so safety is paramount. They must follow established safety protocols, wear appropriate personal protective equipment, and be aware of potential hazards to ensure their safety and the safety of others.

How can I become a successful I&C Technician?

To become a successful I&C Technician, it is important to have a strong educational foundation, continually update your skills and knowledge, and gain hands-on experience. Joining professional organizations, attending industry events, and pursuing certifications can also enhance your career prospects.