Are you a seasoned Instrument Installer seeking a new career path? Discover our professionally built Instrument Installer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

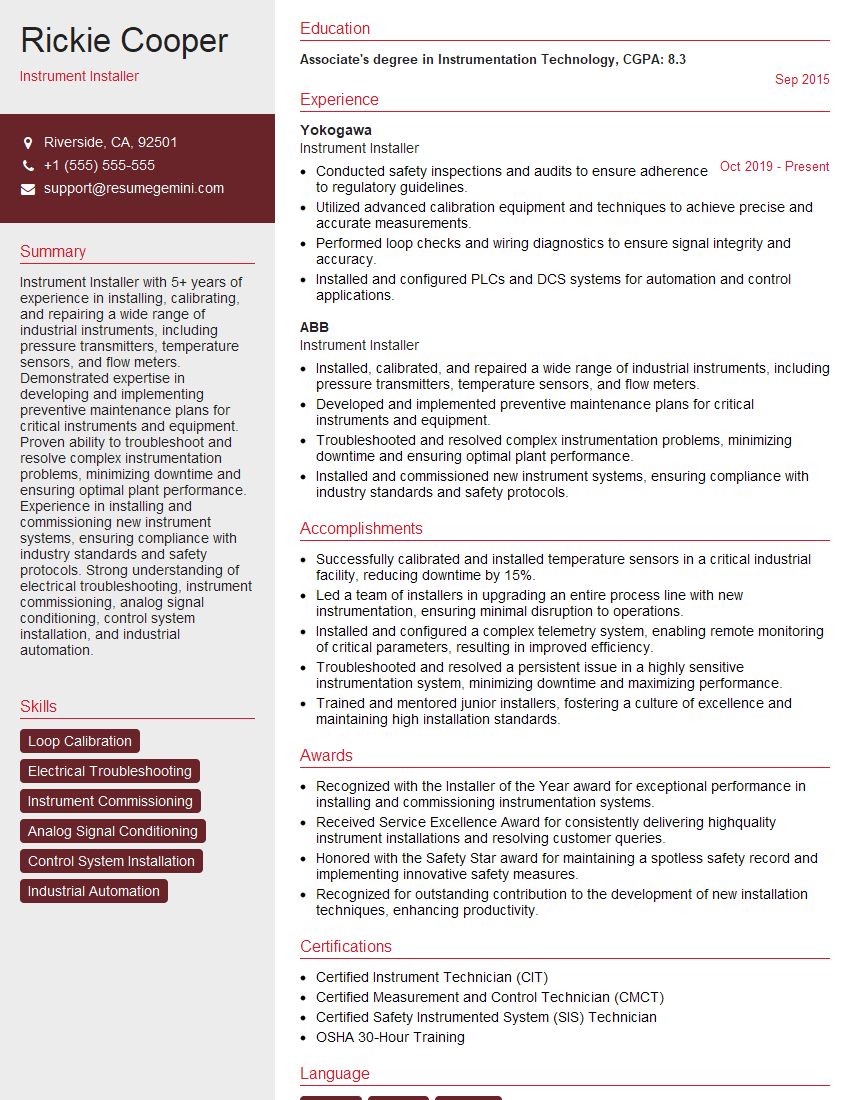

Rickie Cooper

Instrument Installer

Summary

Instrument Installer with 5+ years of experience in installing, calibrating, and repairing a wide range of industrial instruments, including pressure transmitters, temperature sensors, and flow meters. Demonstrated expertise in developing and implementing preventive maintenance plans for critical instruments and equipment. Proven ability to troubleshoot and resolve complex instrumentation problems, minimizing downtime and ensuring optimal plant performance. Experience in installing and commissioning new instrument systems, ensuring compliance with industry standards and safety protocols. Strong understanding of electrical troubleshooting, instrument commissioning, analog signal conditioning, control system installation, and industrial automation.

Education

Associate’s degree in Instrumentation Technology

September 2015

Skills

- Loop Calibration

- Electrical Troubleshooting

- Instrument Commissioning

- Analog Signal Conditioning

- Control System Installation

- Industrial Automation

Work Experience

Instrument Installer

- Conducted safety inspections and audits to ensure adherence to regulatory guidelines.

- Utilized advanced calibration equipment and techniques to achieve precise and accurate measurements.

- Performed loop checks and wiring diagnostics to ensure signal integrity and accuracy.

- Installed and configured PLCs and DCS systems for automation and control applications.

Instrument Installer

- Installed, calibrated, and repaired a wide range of industrial instruments, including pressure transmitters, temperature sensors, and flow meters.

- Developed and implemented preventive maintenance plans for critical instruments and equipment.

- Troubleshooted and resolved complex instrumentation problems, minimizing downtime and ensuring optimal plant performance.

- Installed and commissioned new instrument systems, ensuring compliance with industry standards and safety protocols.

Accomplishments

- Successfully calibrated and installed temperature sensors in a critical industrial facility, reducing downtime by 15%.

- Led a team of installers in upgrading an entire process line with new instrumentation, ensuring minimal disruption to operations.

- Installed and configured a complex telemetry system, enabling remote monitoring of critical parameters, resulting in improved efficiency.

- Troubleshooted and resolved a persistent issue in a highly sensitive instrumentation system, minimizing downtime and maximizing performance.

- Trained and mentored junior installers, fostering a culture of excellence and maintaining high installation standards.

Awards

- Recognized with the Installer of the Year award for exceptional performance in installing and commissioning instrumentation systems.

- Received Service Excellence Award for consistently delivering highquality instrument installations and resolving customer queries.

- Honored with the Safety Star award for maintaining a spotless safety record and implementing innovative safety measures.

- Recognized for outstanding contribution to the development of new installation techniques, enhancing productivity.

Certificates

- Certified Instrument Technician (CIT)

- Certified Measurement and Control Technician (CMCT)

- Certified Safety Instrumented System (SIS) Technician

- OSHA 30-Hour Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Installer

- Highlight your experience in installing, calibrating, and repairing industrial instruments.

- Showcase your skills in troubleshooting and resolving complex instrumentation problems.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Instrument Installer Resume

- Install, calibrate, and repair a wide range of industrial instruments, including pressure transmitters, temperature sensors, and flow meters.

- Develop and implement preventive maintenance plans for critical instruments and equipment.

- Troubleshoot and resolve complex instrumentation problems, minimizing downtime and ensuring optimal plant performance.

- Install and commission new instrument systems, ensuring compliance with industry standards and safety protocols.

- Conduct safety inspections and audits to ensure adherence to regulatory guidelines.

- Utilize advanced calibration equipment and techniques to achieve precise and accurate measurements.

- Perform loop checks and wiring diagnostics to ensure signal integrity and accuracy.

Frequently Asked Questions (FAQ’s) For Instrument Installer

What is the role of an Instrument Installer?

An Instrument Installer is responsible for installing, calibrating, and repairing industrial instruments, such as pressure transmitters, temperature sensors, and flow meters. They also develop and implement preventive maintenance plans for critical instruments and equipment, troubleshoot and resolve complex instrumentation problems, and install and commission new instrument systems.

What are the key skills required to be an Instrument Installer?

Key skills required to be an Instrument Installer include loop calibration, electrical troubleshooting, instrument commissioning, analog signal conditioning, control system installation, and industrial automation.

What is the typical education and experience required to become an Instrument Installer?

Most Instrument Installers have an associate’s degree in Instrumentation Technology or a related field, combined with several years of experience in installing, calibrating, and repairing industrial instruments.

What is the career outlook for Instrument Installers?

The career outlook for Instrument Installers is expected to be good over the next few years. As industrial facilities become more automated, the demand for skilled Instrument Installers is expected to increase.

What is the average salary for Instrument Installers?

The average salary for Instrument Installers varies depending on their experience and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Instrument Installers was $56,990 in May 2020.

What are the benefits of working as an Instrument Installer?

Benefits of working as an Instrument Installer include competitive salaries, opportunities for career advancement, and the chance to work with cutting-edge technology.

What are the challenges of working as an Instrument Installer?

Challenges of working as an Instrument Installer include working in potentially hazardous environments, exposure to extreme temperatures, and the need to be on call for emergencies.