Are you a seasoned Instrument Mechanics Supervisor seeking a new career path? Discover our professionally built Instrument Mechanics Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

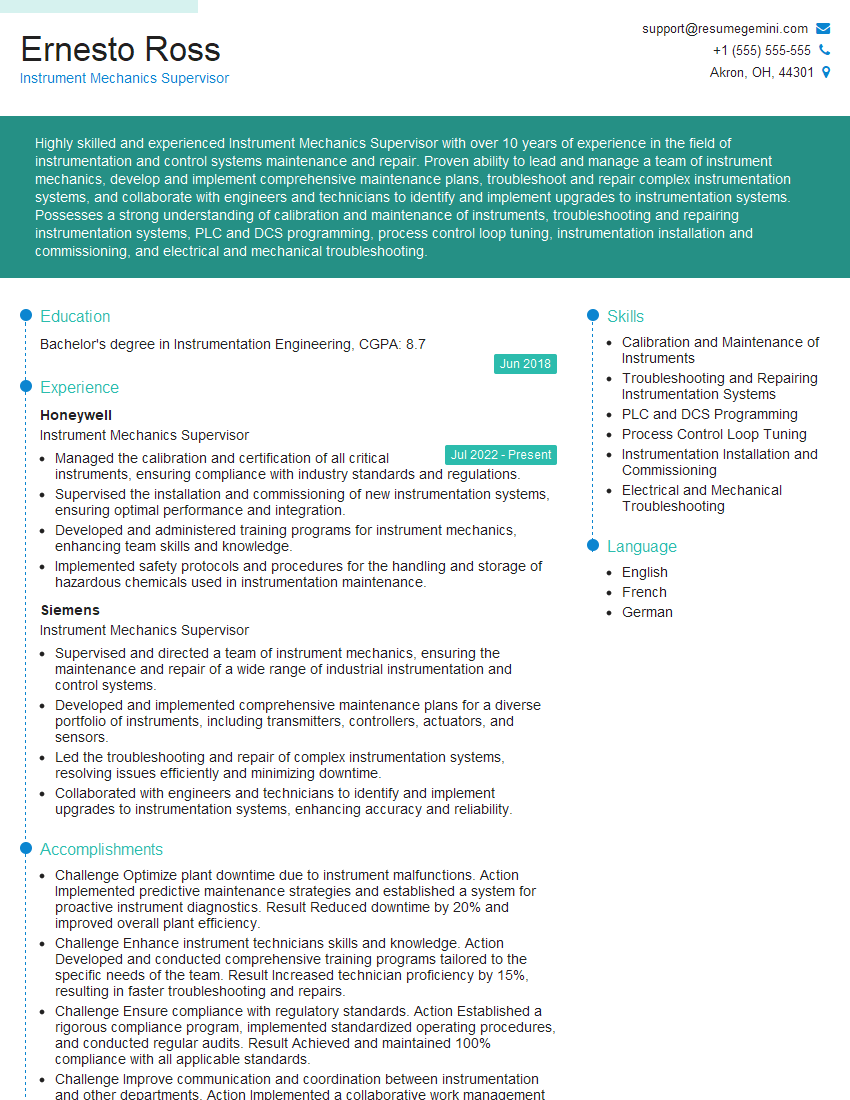

Ernesto Ross

Instrument Mechanics Supervisor

Summary

Highly skilled and experienced Instrument Mechanics Supervisor with over 10 years of experience in the field of instrumentation and control systems maintenance and repair. Proven ability to lead and manage a team of instrument mechanics, develop and implement comprehensive maintenance plans, troubleshoot and repair complex instrumentation systems, and collaborate with engineers and technicians to identify and implement upgrades to instrumentation systems. Possesses a strong understanding of calibration and maintenance of instruments, troubleshooting and repairing instrumentation systems, PLC and DCS programming, process control loop tuning, instrumentation installation and commissioning, and electrical and mechanical troubleshooting.

Education

Bachelor’s degree in Instrumentation Engineering

June 2018

Skills

- Calibration and Maintenance of Instruments

- Troubleshooting and Repairing Instrumentation Systems

- PLC and DCS Programming

- Process Control Loop Tuning

- Instrumentation Installation and Commissioning

- Electrical and Mechanical Troubleshooting

Work Experience

Instrument Mechanics Supervisor

- Managed the calibration and certification of all critical instruments, ensuring compliance with industry standards and regulations.

- Supervised the installation and commissioning of new instrumentation systems, ensuring optimal performance and integration.

- Developed and administered training programs for instrument mechanics, enhancing team skills and knowledge.

- Implemented safety protocols and procedures for the handling and storage of hazardous chemicals used in instrumentation maintenance.

Instrument Mechanics Supervisor

- Supervised and directed a team of instrument mechanics, ensuring the maintenance and repair of a wide range of industrial instrumentation and control systems.

- Developed and implemented comprehensive maintenance plans for a diverse portfolio of instruments, including transmitters, controllers, actuators, and sensors.

- Led the troubleshooting and repair of complex instrumentation systems, resolving issues efficiently and minimizing downtime.

- Collaborated with engineers and technicians to identify and implement upgrades to instrumentation systems, enhancing accuracy and reliability.

Accomplishments

- Challenge Optimize plant downtime due to instrument malfunctions. Action Implemented predictive maintenance strategies and established a system for proactive instrument diagnostics. Result Reduced downtime by 20% and improved overall plant efficiency.

- Challenge Enhance instrument technicians skills and knowledge. Action Developed and conducted comprehensive training programs tailored to the specific needs of the team. Result Increased technician proficiency by 15%, resulting in faster troubleshooting and repairs.

- Challenge Ensure compliance with regulatory standards. Action Established a rigorous compliance program, implemented standardized operating procedures, and conducted regular audits. Result Achieved and maintained 100% compliance with all applicable standards.

- Challenge Improve communication and coordination between instrumentation and other departments. Action Implemented a collaborative work management system and fostered open communication channels. Result Enhanced teamwork and streamlined project execution, leading to reduced project delays.

- Challenge Implement a costeffective instrumentation maintenance program. Action Evaluated existing maintenance practices, identified areas for optimization, and implemented a proactive maintenance strategy. Result Reduced maintenance costs by 10% while ensuring the reliability and accuracy of instrumentation systems.

Awards

- Recognized with the Instrument Maintenance Excellence Award for exceptional performance in managing and maintaining instrumentation systems, ensuring optimal plant operations.

- Received the Supervisor of the Year award for outstanding leadership and guidance in developing and motivating a highly skilled team of instrument mechanics.

- Awarded the Safety Champion recognition for promoting best safety practices and maintaining a hazardfree work environment within the instrumentation department.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Automation Professional (CAP)

- Certified Measurement and Test Equipment Technician (CMTT)

- Certified Pressure Calibration Technician (CPCT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Mechanics Supervisor

- Highlight your experience in leading and managing a team of instrument mechanics.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Emphasize your skills in troubleshooting and repairing complex instrumentation systems.

- Showcase your knowledge of calibration and maintenance of instruments, PLC and DCS programming, process control loop tuning, instrumentation installation and commissioning, and electrical and mechanical troubleshooting.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Instrument Mechanics Supervisor Resume

- Supervising and directing a team of instrument mechanics, ensuring the maintenance and repair of a wide range of industrial instrumentation and control systems.

- Developing and implementing comprehensive maintenance plans for a diverse portfolio of instruments, including transmitters, controllers, actuators, and sensors.

- Leading the troubleshooting and repair of complex instrumentation systems, resolving issues efficiently and minimizing downtime.

- Collaborating with engineers and technicians to identify and implement upgrades to instrumentation systems, enhancing accuracy and reliability.

- Managing the calibration and certification of all critical instruments, ensuring compliance with industry standards and regulations.

- Supervising the installation and commissioning of new instrumentation systems, ensuring optimal performance and integration.

- Developing and administering training programs for instrument mechanics, enhancing team skills and knowledge.

- Implementing safety protocols and procedures for the handling and storage of hazardous chemicals used in instrumentation maintenance.

Frequently Asked Questions (FAQ’s) For Instrument Mechanics Supervisor

What are the key responsibilities of an Instrument Mechanics Supervisor?

The key responsibilities of an Instrument Mechanics Supervisor include supervising and directing a team of instrument mechanics, developing and implementing comprehensive maintenance plans, troubleshooting and repairing complex instrumentation systems, collaborating with engineers and technicians to identify and implement upgrades to instrumentation systems, managing the calibration and certification of all critical instruments, supervising the installation and commissioning of new instrumentation systems, developing and administering training programs for instrument mechanics, and implementing safety protocols and procedures for the handling and storage of hazardous chemicals used in instrumentation maintenance.

What are the qualifications for an Instrument Mechanics Supervisor?

The qualifications for an Instrument Mechanics Supervisor typically include a bachelor’s degree in Instrumentation Engineering or a related field, as well as several years of experience in the field of instrumentation and control systems maintenance and repair. Additionally, Instrument Mechanics Supervisors should possess strong leadership and management skills, as well as a thorough understanding of calibration and maintenance of instruments, troubleshooting and repairing instrumentation systems, PLC and DCS programming, process control loop tuning, instrumentation installation and commissioning, and electrical and mechanical troubleshooting.

What are the career prospects for an Instrument Mechanics Supervisor?

The career prospects for an Instrument Mechanics Supervisor are generally good. As the demand for skilled instrument mechanics continues to grow, so too will the demand for qualified Instrument Mechanics Supervisors. Instrument Mechanics Supervisors can advance to more senior management positions, such as Maintenance Manager or Plant Manager, or they can specialize in a particular area of instrumentation and control, such as process control or automation.

What are the challenges of being an Instrument Mechanics Supervisor?

The challenges of being an Instrument Mechanics Supervisor can include managing a team of instrument mechanics, developing and implementing comprehensive maintenance plans, troubleshooting and repairing complex instrumentation systems, collaborating with engineers and technicians to identify and implement upgrades to instrumentation systems, managing the calibration and certification of all critical instruments, supervising the installation and commissioning of new instrumentation systems, developing and administering training programs for instrument mechanics, and implementing safety protocols and procedures for the handling and storage of hazardous chemicals used in instrumentation maintenance.

What are the rewards of being an Instrument Mechanics Supervisor?

The rewards of being an Instrument Mechanics Supervisor can include a competitive salary, comprehensive benefits package, and the opportunity to work in a challenging and rewarding field. Instrument Mechanics Supervisors play a vital role in ensuring the safe and efficient operation of industrial facilities, and they have the opportunity to make a real difference in the world.

What is the average salary for an Instrument Mechanics Supervisor?

The average salary for an Instrument Mechanics Supervisor in the United States is around $75,000 per year. However, salaries can vary depending on experience, education, location, and employer.

What is the job outlook for Instrument Mechanics Supervisors?

The job outlook for Instrument Mechanics Supervisors is expected to be good over the next few years. As the demand for skilled instrument mechanics continues to grow, so too will the demand for qualified Instrument Mechanics Supervisors.

What are the most important skills for an Instrument Mechanics Supervisor?

The most important skills for an Instrument Mechanics Supervisor include leadership and management, troubleshooting and repairing instrumentation systems, calibration and maintenance of instruments, PLC and DCS programming, process control loop tuning, instrumentation installation and commissioning, and electrical and mechanical troubleshooting.