Are you a seasoned Instrumentation/Controls/Electrical Systems Technician (ICE Technician) seeking a new career path? Discover our professionally built Instrumentation/Controls/Electrical Systems Technician (ICE Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

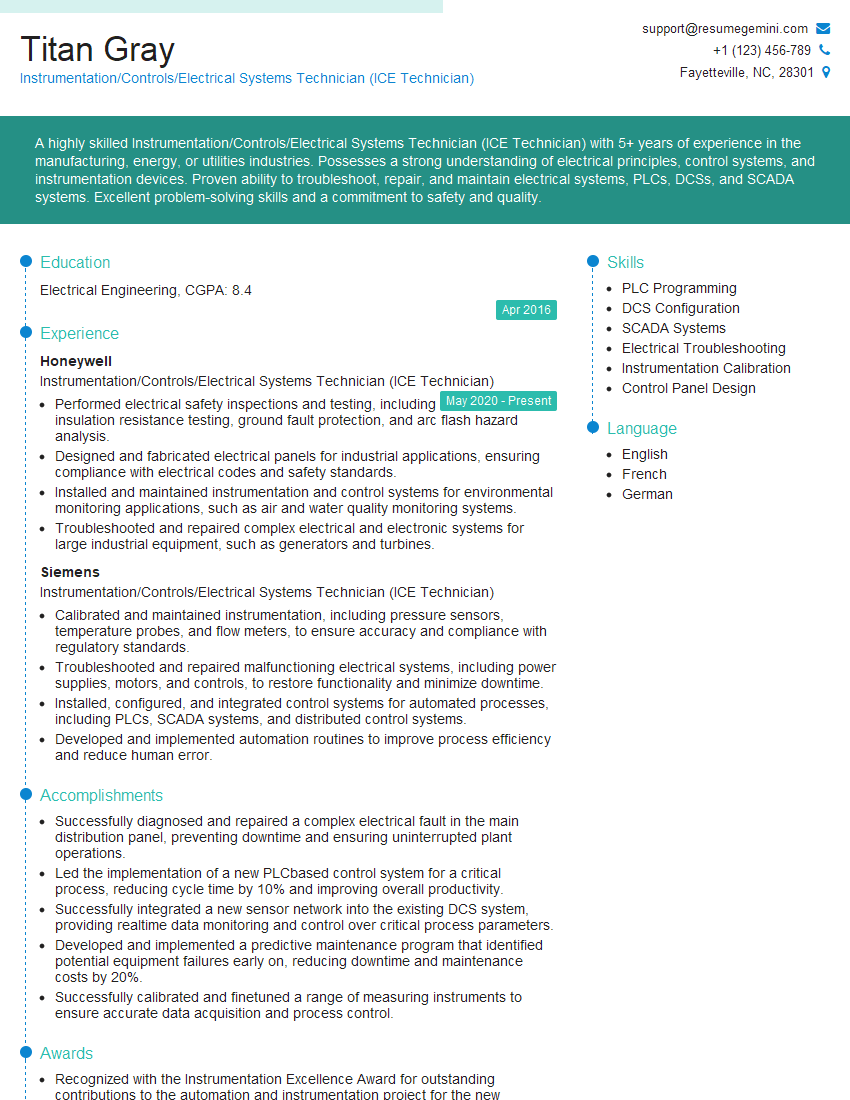

Titan Gray

Instrumentation/Controls/Electrical Systems Technician (ICE Technician)

Summary

A highly skilled Instrumentation/Controls/Electrical Systems Technician (ICE Technician) with 5+ years of experience in the manufacturing, energy, or utilities industries. Possesses a strong understanding of electrical principles, control systems, and instrumentation devices. Proven ability to troubleshoot, repair, and maintain electrical systems, PLCs, DCSs, and SCADA systems. Excellent problem-solving skills and a commitment to safety and quality.

Education

Electrical Engineering

April 2016

Skills

- PLC Programming

- DCS Configuration

- SCADA Systems

- Electrical Troubleshooting

- Instrumentation Calibration

- Control Panel Design

Work Experience

Instrumentation/Controls/Electrical Systems Technician (ICE Technician)

- Performed electrical safety inspections and testing, including insulation resistance testing, ground fault protection, and arc flash hazard analysis.

- Designed and fabricated electrical panels for industrial applications, ensuring compliance with electrical codes and safety standards.

- Installed and maintained instrumentation and control systems for environmental monitoring applications, such as air and water quality monitoring systems.

- Troubleshooted and repaired complex electrical and electronic systems for large industrial equipment, such as generators and turbines.

Instrumentation/Controls/Electrical Systems Technician (ICE Technician)

- Calibrated and maintained instrumentation, including pressure sensors, temperature probes, and flow meters, to ensure accuracy and compliance with regulatory standards.

- Troubleshooted and repaired malfunctioning electrical systems, including power supplies, motors, and controls, to restore functionality and minimize downtime.

- Installed, configured, and integrated control systems for automated processes, including PLCs, SCADA systems, and distributed control systems.

- Developed and implemented automation routines to improve process efficiency and reduce human error.

Accomplishments

- Successfully diagnosed and repaired a complex electrical fault in the main distribution panel, preventing downtime and ensuring uninterrupted plant operations.

- Led the implementation of a new PLCbased control system for a critical process, reducing cycle time by 10% and improving overall productivity.

- Successfully integrated a new sensor network into the existing DCS system, providing realtime data monitoring and control over critical process parameters.

- Developed and implemented a predictive maintenance program that identified potential equipment failures early on, reducing downtime and maintenance costs by 20%.

- Successfully calibrated and finetuned a range of measuring instruments to ensure accurate data acquisition and process control.

Awards

- Recognized with the Instrumentation Excellence Award for outstanding contributions to the automation and instrumentation project for the new production line.

- Received the Controls System Innovation Award for developing a novel automated control system that improved production efficiency by 15%.

- Recognized with the ICE Technician of the Year Award for consistently exceeding expectations in troubleshooting and resolving instrumentation, controls, and electrical issues.

- Received the Project Leadership Award for managing a complex instrumentation and controls project that resulted in significant cost savings and improved process reliability.

Certificates

- ISA Certified Automation Professional (CAP)

- NCSU Certified Maintenance and Reliability Technician (CMRT)

- NCEES Principles and Practice of Engineering Exam

- OSHA 10-Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrumentation/Controls/Electrical Systems Technician (ICE Technician)

- Highlight your skills and experience: In your resume, clearly list your relevant skills and experience in instrumentation, controls, and electrical systems.

- Demonstrate your problem-solving abilities: Provide specific examples of how you have successfully troubleshooted and resolved complex electrical and instrumentation issues.

- Showcase your commitment to safety: Emphasize your adherence to safety protocols and your knowledge of electrical codes and standards.

- Quantify your accomplishments: Whenever possible, include specific numbers and metrics to demonstrate the impact of your work on efficiency, cost savings, or other relevant factors.

Essential Experience Highlights for a Strong Instrumentation/Controls/Electrical Systems Technician (ICE Technician) Resume

- Calibrating and maintaining instrumentation, including pressure sensors, temperature probes, and flow meters, to ensure accuracy and compliance with regulatory standards.

- Troubleshooting and repairing malfunctioning electrical systems, including power supplies, motors, and controls, to restore functionality and minimize downtime.

- Installing, configuring, and integrating control systems for automated processes, including PLCs, SCADA systems, and distributed control systems.

- Developing and implementing automation routines to improve process efficiency and reduce human error.

- Performing electrical safety inspections and testing, including insulation resistance testing, ground fault protection, and arc flash hazard analysis.

- Designing and fabricating electrical panels for industrial applications, ensuring compliance with electrical codes and safety standards.

Frequently Asked Questions (FAQ’s) For Instrumentation/Controls/Electrical Systems Technician (ICE Technician)

What is the role of an ICE Technician?

An ICE Technician is responsible for the installation, maintenance, and repair of instrumentation, controls, and electrical systems in industrial settings. This includes ensuring the accuracy of instrumentation devices, troubleshooting electrical faults, and integrating control systems for automated processes.

What are the qualifications required to become an ICE Technician?

Typically, an ICE Technician requires a degree in Electrical Engineering or a related field, along with relevant experience in instrumentation, controls, and electrical systems.

What are the key skills for an ICE Technician?

Key skills for an ICE Technician include proficiency in PLC programming, DCS configuration, SCADA systems, electrical troubleshooting, instrumentation calibration, and control panel design.

What industries employ ICE Technicians?

ICE Technicians are in demand in various industries, including manufacturing, energy, utilities, and process control.

What are the career prospects for an ICE Technician?

ICE Technicians with strong skills and experience can advance to roles such as Lead Technician, Control Systems Engineer, or Project Manager.

How can I improve my skills as an ICE Technician?

To enhance your skills as an ICE Technician, consider obtaining industry certifications, attending training programs, and staying updated with the latest technologies and advancements in the field.