Are you a seasoned Instrumentation Fitter seeking a new career path? Discover our professionally built Instrumentation Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

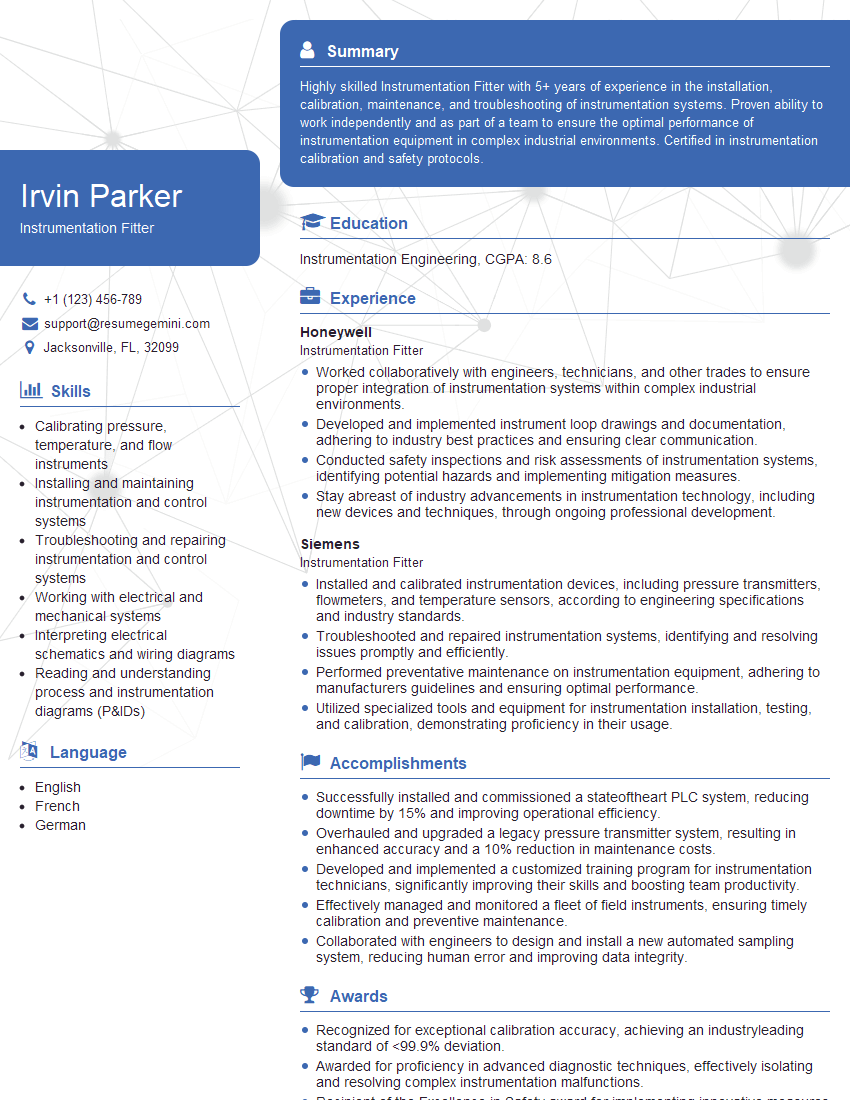

Irvin Parker

Instrumentation Fitter

Summary

Highly skilled Instrumentation Fitter with 5+ years of experience in the installation, calibration, maintenance, and troubleshooting of instrumentation systems. Proven ability to work independently and as part of a team to ensure the optimal performance of instrumentation equipment in complex industrial environments. Certified in instrumentation calibration and safety protocols.

Education

Instrumentation Engineering

April 2019

Skills

- Calibrating pressure, temperature, and flow instruments

- Installing and maintaining instrumentation and control systems

- Troubleshooting and repairing instrumentation and control systems

- Working with electrical and mechanical systems

- Interpreting electrical schematics and wiring diagrams

- Reading and understanding process and instrumentation diagrams (P&IDs)

Work Experience

Instrumentation Fitter

- Worked collaboratively with engineers, technicians, and other trades to ensure proper integration of instrumentation systems within complex industrial environments.

- Developed and implemented instrument loop drawings and documentation, adhering to industry best practices and ensuring clear communication.

- Conducted safety inspections and risk assessments of instrumentation systems, identifying potential hazards and implementing mitigation measures.

- Stay abreast of industry advancements in instrumentation technology, including new devices and techniques, through ongoing professional development.

Instrumentation Fitter

- Installed and calibrated instrumentation devices, including pressure transmitters, flowmeters, and temperature sensors, according to engineering specifications and industry standards.

- Troubleshooted and repaired instrumentation systems, identifying and resolving issues promptly and efficiently.

- Performed preventative maintenance on instrumentation equipment, adhering to manufacturers guidelines and ensuring optimal performance.

- Utilized specialized tools and equipment for instrumentation installation, testing, and calibration, demonstrating proficiency in their usage.

Accomplishments

- Successfully installed and commissioned a stateoftheart PLC system, reducing downtime by 15% and improving operational efficiency.

- Overhauled and upgraded a legacy pressure transmitter system, resulting in enhanced accuracy and a 10% reduction in maintenance costs.

- Developed and implemented a customized training program for instrumentation technicians, significantly improving their skills and boosting team productivity.

- Effectively managed and monitored a fleet of field instruments, ensuring timely calibration and preventive maintenance.

- Collaborated with engineers to design and install a new automated sampling system, reducing human error and improving data integrity.

Awards

- Recognized for exceptional calibration accuracy, achieving an industryleading standard of <99.9% deviation.

- Awarded for proficiency in advanced diagnostic techniques, effectively isolating and resolving complex instrumentation malfunctions.

- Recipient of the Excellence in Safety award for implementing innovative measures that enhanced the safety of instrumentation systems.

Certificates

- Certified Instrumentation Fitter (CIF)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Manager (CMM)

- Certified Reliability Engineer (CRE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrumentation Fitter

- Highlight your technical skills and experience in the instrumentation field.

- Demonstrate your problem-solving abilities and troubleshooting expertise.

- Showcase your knowledge of industry standards and best practices.

- Emphasize your commitment to safety and quality.

- Quantify your accomplishments and results whenever possible.

Essential Experience Highlights for a Strong Instrumentation Fitter Resume

- Installed, calibrated, and maintained instrumentation devices such as pressure transmitters, flowmeters, and temperature sensors.

- Troubleshooted and repaired instrumentation systems, identifying and resolving issues promptly and efficiently.

- Performed preventative maintenance on instrumentation equipment, adhering to manufacturers’ guidelines and ensuring optimal performance.

- Utilized specialized tools and equipment for instrumentation installation, testing, and calibration.

- Worked collaboratively with engineers, technicians, and other trades to ensure proper integration of instrumentation systems within complex industrial environments.

- Developed and implemented instrument loop drawings and documentation, adhering to industry best practices and ensuring clear communication.

Frequently Asked Questions (FAQ’s) For Instrumentation Fitter

What is the role of an Instrumentation Fitter?

An Instrumentation Fitter is responsible for installing, calibrating, maintaining, and troubleshooting instrumentation systems in industrial settings. This includes working with various instruments such as pressure transmitters, flowmeters, and temperature sensors to ensure accurate and reliable data collection and control.

What are the essential skills for an Instrumentation Fitter?

Essential skills for an Instrumentation Fitter include: proficiency in installing, calibrating, and maintaining instrumentation devices; troubleshooting and repairing instrumentation systems; performing preventative maintenance; utilizing specialized tools and equipment; working collaboratively with other professionals; and adhering to safety protocols.

What industries employ Instrumentation Fitters?

Instrumentation Fitters are employed in various industries that rely on instrumentation systems for monitoring and control, such as oil and gas, power generation, manufacturing, and pharmaceuticals.

What is the career path for an Instrumentation Fitter?

With experience and additional training, Instrumentation Fitters can advance to roles such as Instrumentation Technician, Instrumentation Engineer, or Maintenance Supervisor.

What are the safety considerations for Instrumentation Fitters?

Instrumentation Fitters must adhere to strict safety protocols when working with instrumentation systems, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards such as electrical shock, pressure leaks, and hazardous chemicals.

How can I become an Instrumentation Fitter?

To become an Instrumentation Fitter, individuals typically complete a vocational training program or apprenticeship in instrumentation or a related field. Relevant certifications and ongoing professional development are also beneficial.