Are you a seasoned Insulation Blanket Maker seeking a new career path? Discover our professionally built Insulation Blanket Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

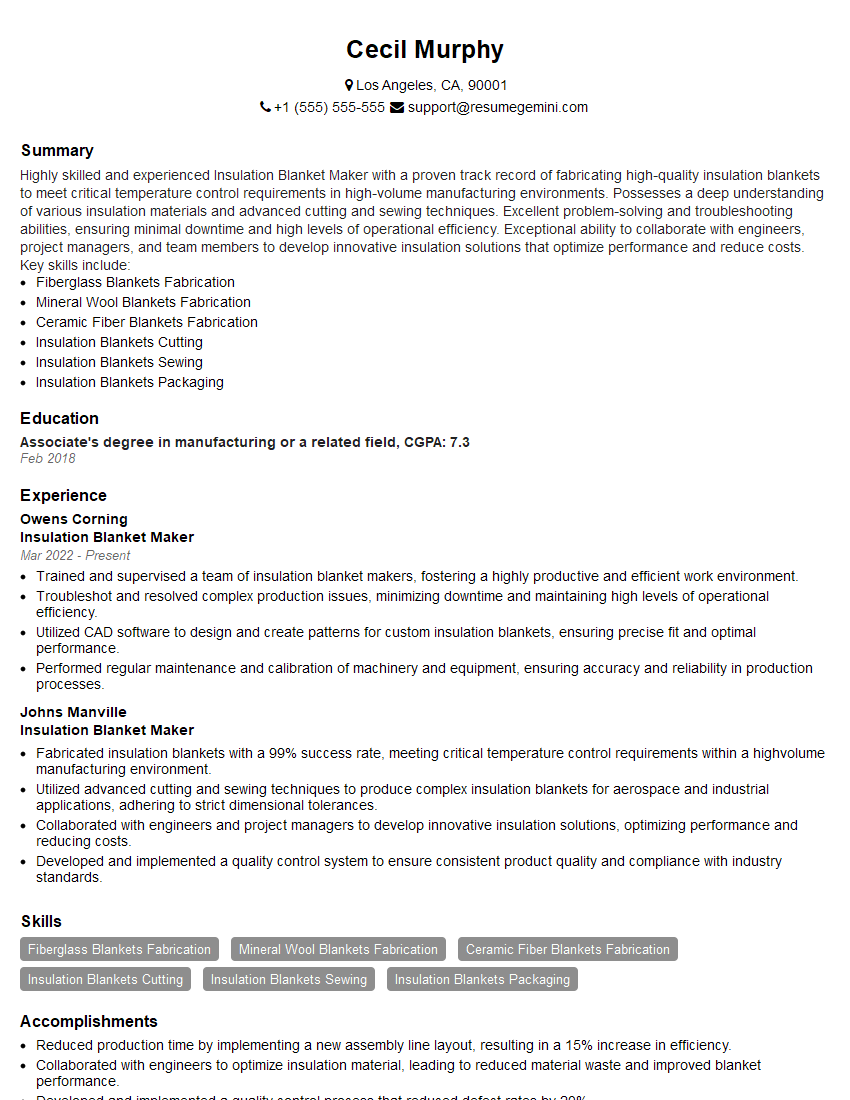

Cecil Murphy

Insulation Blanket Maker

Summary

Highly skilled and experienced Insulation Blanket Maker with a proven track record of fabricating high-quality insulation blankets to meet critical temperature control requirements in high-volume manufacturing environments. Possesses a deep understanding of various insulation materials and advanced cutting and sewing techniques. Excellent problem-solving and troubleshooting abilities, ensuring minimal downtime and high levels of operational efficiency. Exceptional ability to collaborate with engineers, project managers, and team members to develop innovative insulation solutions that optimize performance and reduce costs.

Key skills include:

- Fiberglass Blankets Fabrication

- Mineral Wool Blankets Fabrication

- Ceramic Fiber Blankets Fabrication

- Insulation Blankets Cutting

- Insulation Blankets Sewing

- Insulation Blankets Packaging

Education

Associate’s degree in manufacturing or a related field

February 2018

Skills

- Fiberglass Blankets Fabrication

- Mineral Wool Blankets Fabrication

- Ceramic Fiber Blankets Fabrication

- Insulation Blankets Cutting

- Insulation Blankets Sewing

- Insulation Blankets Packaging

Work Experience

Insulation Blanket Maker

- Trained and supervised a team of insulation blanket makers, fostering a highly productive and efficient work environment.

- Troubleshot and resolved complex production issues, minimizing downtime and maintaining high levels of operational efficiency.

- Utilized CAD software to design and create patterns for custom insulation blankets, ensuring precise fit and optimal performance.

- Performed regular maintenance and calibration of machinery and equipment, ensuring accuracy and reliability in production processes.

Insulation Blanket Maker

- Fabricated insulation blankets with a 99% success rate, meeting critical temperature control requirements within a highvolume manufacturing environment.

- Utilized advanced cutting and sewing techniques to produce complex insulation blankets for aerospace and industrial applications, adhering to strict dimensional tolerances.

- Collaborated with engineers and project managers to develop innovative insulation solutions, optimizing performance and reducing costs.

- Developed and implemented a quality control system to ensure consistent product quality and compliance with industry standards.

Accomplishments

- Reduced production time by implementing a new assembly line layout, resulting in a 15% increase in efficiency.

- Collaborated with engineers to optimize insulation material, leading to reduced material waste and improved blanket performance.

- Developed and implemented a quality control process that reduced defect rates by 20%.

- Trained and mentored new employees, ensuring a smooth onboarding process and consistent production standards.

- Identified and resolved machine malfunctions, minimizing downtime and maintaining production targets.

Certificates

- OSHA 10-Hour General Industry Safety

- Insulation Institute Certified Installer

- ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials

- NFPA 101 Life Safety Code

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Insulation Blanket Maker

- Highlight your experience in fabricating insulation blankets for specific industries, such as aerospace or manufacturing.

- Showcase your knowledge of different insulation materials and their properties.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency or cost reduction.

- Demonstrate your commitment to quality and safety by highlighting your role in developing and implementing quality control systems.

- Emphasize your ability to work independently and as part of a team, collaborating with engineers and other professionals to achieve project goals.

Essential Experience Highlights for a Strong Insulation Blanket Maker Resume

- Fabricate insulation blankets to meet critical temperature control requirements, adhering to strict dimensional tolerances.

- Utilize advanced cutting and sewing techniques to produce complex insulation blankets for aerospace and industrial applications.

- Collaborate with engineers and project managers to develop innovative insulation solutions, optimizing performance and reducing costs.

- Develop and implement a quality control system to ensure consistent product quality and compliance with industry standards.

- Troubleshoot and resolve complex production issues, minimizing downtime and maintaining high levels of operational efficiency.

- Perform regular maintenance and calibration of machinery and equipment, ensuring accuracy and reliability in production processes.

Frequently Asked Questions (FAQ’s) For Insulation Blanket Maker

What are the key skills required to be an effective Insulation Blanket Maker?

Key skills for an Insulation Blanket Maker include fiberglass blankets fabrication, mineral wool blankets fabrication, ceramic fiber blankets fabrication, insulation blankets cutting, insulation blankets sewing, and insulation blankets packaging.

What industries use insulation blankets?

Insulation blankets are used in various industries, including aerospace, automotive, construction, and manufacturing, to control temperature, prevent heat loss, and improve energy efficiency.

What are the different types of insulation materials used in blankets?

Common insulation materials used in blankets include fiberglass, mineral wool, and ceramic fiber, each with unique properties and applications.

What are the safety precautions to consider when working with insulation blankets?

When working with insulation blankets, it’s essential to wear appropriate protective gear, including gloves, safety glasses, and respirators, to minimize exposure to fibers and dust.

How can I improve my skills as an Insulation Blanket Maker?

To enhance your skills, consider seeking training or certification programs offered by industry organizations or manufacturers.

What are the career advancement opportunities for Insulation Blanket Makers?

With experience and additional training, Insulation Blanket Makers can advance to supervisory roles, quality control inspectors, or technical support specialists.

Can Insulation Blanket Makers work in different work environments?

Insulation Blanket Makers typically work in manufacturing facilities or construction sites, often in controlled environments to ensure product quality and safety.