Are you a seasoned Internal Grinder Set-Up Operator seeking a new career path? Discover our professionally built Internal Grinder Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

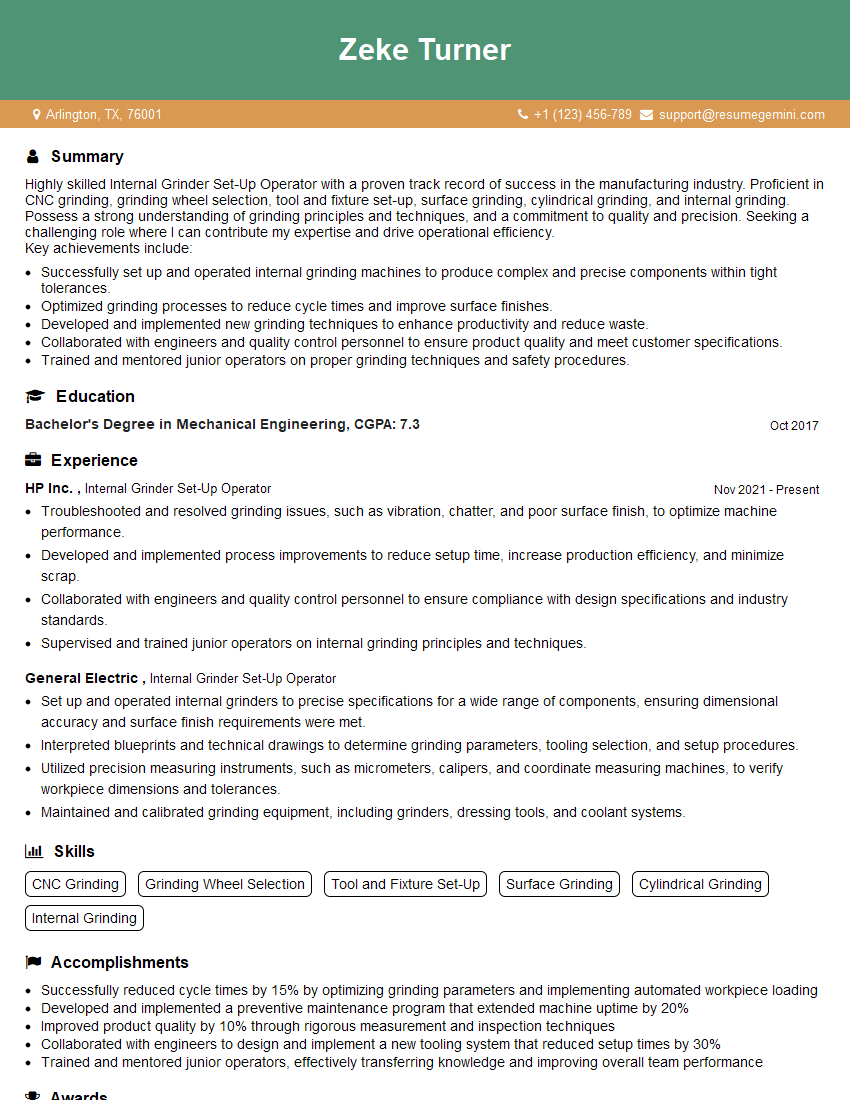

Zeke Turner

Internal Grinder Set-Up Operator

Summary

Highly skilled Internal Grinder Set-Up Operator with a proven track record of success in the manufacturing industry. Proficient in CNC grinding, grinding wheel selection, tool and fixture set-up, surface grinding, cylindrical grinding, and internal grinding. Possess a strong understanding of grinding principles and techniques, and a commitment to quality and precision. Seeking a challenging role where I can contribute my expertise and drive operational efficiency.

Key achievements include:

- Successfully set up and operated internal grinding machines to produce complex and precise components within tight tolerances.

- Optimized grinding processes to reduce cycle times and improve surface finishes.

- Developed and implemented new grinding techniques to enhance productivity and reduce waste.

- Collaborated with engineers and quality control personnel to ensure product quality and meet customer specifications.

- Trained and mentored junior operators on proper grinding techniques and safety procedures.

Education

Bachelor’s Degree in Mechanical Engineering

October 2017

Skills

- CNC Grinding

- Grinding Wheel Selection

- Tool and Fixture Set-Up

- Surface Grinding

- Cylindrical Grinding

- Internal Grinding

Work Experience

Internal Grinder Set-Up Operator

- Troubleshooted and resolved grinding issues, such as vibration, chatter, and poor surface finish, to optimize machine performance.

- Developed and implemented process improvements to reduce setup time, increase production efficiency, and minimize scrap.

- Collaborated with engineers and quality control personnel to ensure compliance with design specifications and industry standards.

- Supervised and trained junior operators on internal grinding principles and techniques.

Internal Grinder Set-Up Operator

- Set up and operated internal grinders to precise specifications for a wide range of components, ensuring dimensional accuracy and surface finish requirements were met.

- Interpreted blueprints and technical drawings to determine grinding parameters, tooling selection, and setup procedures.

- Utilized precision measuring instruments, such as micrometers, calipers, and coordinate measuring machines, to verify workpiece dimensions and tolerances.

- Maintained and calibrated grinding equipment, including grinders, dressing tools, and coolant systems.

Accomplishments

- Successfully reduced cycle times by 15% by optimizing grinding parameters and implementing automated workpiece loading

- Developed and implemented a preventive maintenance program that extended machine uptime by 20%

- Improved product quality by 10% through rigorous measurement and inspection techniques

- Collaborated with engineers to design and implement a new tooling system that reduced setup times by 30%

- Trained and mentored junior operators, effectively transferring knowledge and improving overall team performance

Awards

- Recognized for outstanding performance and contributions to the grinding department

- Received a company award for exceptional customer service

- Recognized for achieving the highest production targets

Certificates

- Certified Grinding Technician (CGT)

- ISO 9001:2015

- ASME B46.1 Surface Texture

- OSHA 30-Hour General Industry

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Internal Grinder Set-Up Operator

- Highlight your experience and skills in CNC grinding, tool and fixture set-up, and grinding wheel selection.

- Provide specific examples of how you have improved grinding processes and reduced cycle times.

- Emphasize your understanding of grinding principles and techniques, and your commitment to quality.

- Tailor your resume to the specific requirements of each job you apply for.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Internal Grinder Set-Up Operator Resume

- Set up and operate internal grinding machines according to specifications.

- Select and install grinding wheels and other tooling.

- Adjust and calibrate machines to ensure accuracy and precision.

- Monitor grinding processes and make necessary adjustments to maintain quality.

- Inspect and measure finished parts to ensure they meet specifications.

- Maintain and troubleshoot grinding machines to minimize downtime.

- Follow safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Internal Grinder Set-Up Operator

What is the role of an Internal Grinder Set-Up Operator?

An Internal Grinder Set-Up Operator is responsible for setting up and operating internal grinding machines to produce complex and precise components. They select and install grinding wheels and other tooling, adjust and calibrate machines to ensure accuracy and precision, monitor grinding processes and make necessary adjustments to maintain quality, and inspect and measure finished parts to ensure they meet specifications.

What are the key skills required for an Internal Grinder Set-Up Operator?

Key skills for an Internal Grinder Set-Up Operator include CNC grinding, grinding wheel selection, tool and fixture set-up, surface grinding, cylindrical grinding, and internal grinding. They should also have a strong understanding of grinding principles and techniques, and a commitment to quality and precision.

What is the work environment of an Internal Grinder Set-Up Operator like?

Internal Grinder Set-Up Operators typically work in a manufacturing environment, operating grinding machines in a workshop or factory setting. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the career prospects for an Internal Grinder Set-Up Operator?

Internal Grinder Set-Up Operators with experience and skills can advance to supervisory or management positions within the manufacturing industry. They may also specialize in a particular type of grinding, such as CNC grinding or internal grinding, and become experts in that field.

What is the salary range for an Internal Grinder Set-Up Operator?

The salary range for an Internal Grinder Set-Up Operator can vary depending on experience, skills, and location. According to Salary.com, the average salary for an Internal Grinder Set-Up Operator in the United States is $26.50 per hour.

What are the benefits of working as an Internal Grinder Set-Up Operator?

Benefits of working as an Internal Grinder Set-Up Operator can include a competitive salary, health insurance, paid time off, and opportunities for advancement. They may also have the opportunity to work with cutting-edge technology and be involved in the production of high-quality products.

What are the challenges of working as an Internal Grinder Set-Up Operator?

Challenges of working as an Internal Grinder Set-Up Operator can include working in a noisy and dusty environment, operating heavy machinery, and meeting tight production deadlines. They may also be required to work overtime or on weekends to meet production demands.

What is the job outlook for Internal Grinder Set-Up Operators?

The job outlook for Internal Grinder Set-Up Operators is expected to be positive over the next few years. As the manufacturing industry continues to grow, there will be an increasing demand for skilled workers who can operate and maintain grinding machines.