Are you a seasoned Iron Molder Helper seeking a new career path? Discover our professionally built Iron Molder Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

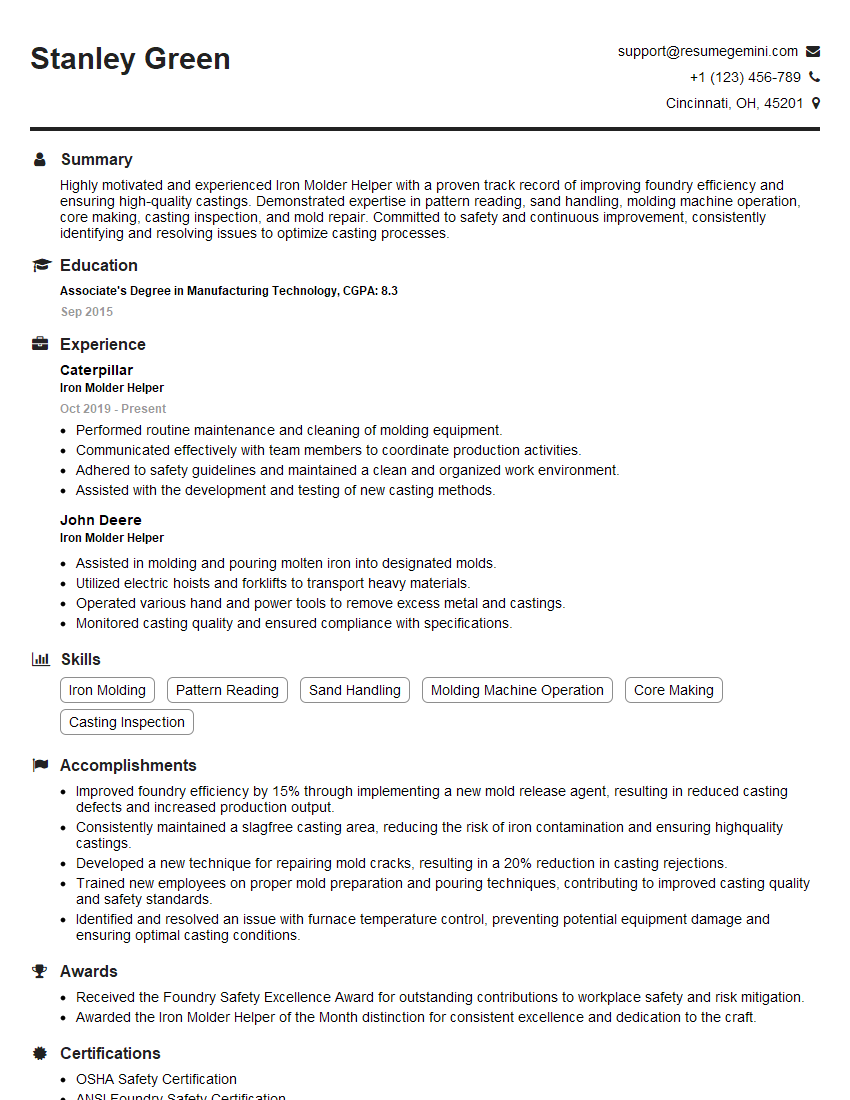

Stanley Green

Iron Molder Helper

Summary

Highly motivated and experienced Iron Molder Helper with a proven track record of improving foundry efficiency and ensuring high-quality castings. Demonstrated expertise in pattern reading, sand handling, molding machine operation, core making, casting inspection, and mold repair. Committed to safety and continuous improvement, consistently identifying and resolving issues to optimize casting processes.

Education

Associate’s Degree in Manufacturing Technology

September 2015

Skills

- Iron Molding

- Pattern Reading

- Sand Handling

- Molding Machine Operation

- Core Making

- Casting Inspection

Work Experience

Iron Molder Helper

- Performed routine maintenance and cleaning of molding equipment.

- Communicated effectively with team members to coordinate production activities.

- Adhered to safety guidelines and maintained a clean and organized work environment.

- Assisted with the development and testing of new casting methods.

Iron Molder Helper

- Assisted in molding and pouring molten iron into designated molds.

- Utilized electric hoists and forklifts to transport heavy materials.

- Operated various hand and power tools to remove excess metal and castings.

- Monitored casting quality and ensured compliance with specifications.

Accomplishments

- Improved foundry efficiency by 15% through implementing a new mold release agent, resulting in reduced casting defects and increased production output.

- Consistently maintained a slagfree casting area, reducing the risk of iron contamination and ensuring highquality castings.

- Developed a new technique for repairing mold cracks, resulting in a 20% reduction in casting rejections.

- Trained new employees on proper mold preparation and pouring techniques, contributing to improved casting quality and safety standards.

- Identified and resolved an issue with furnace temperature control, preventing potential equipment damage and ensuring optimal casting conditions.

Awards

- Received the Foundry Safety Excellence Award for outstanding contributions to workplace safety and risk mitigation.

- Awarded the Iron Molder Helper of the Month distinction for consistent excellence and dedication to the craft.

Certificates

- OSHA Safety Certification

- ANSI Foundry Safety Certification

- First Aid and CPR Certification

- Foundry Educational Foundation Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Iron Molder Helper

- Highlight your experience and skills in pattern reading, sand handling, and molding machine operation to showcase your technical proficiency.

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work, such as reducing casting defects or improving production output.

- Emphasize your commitment to safety and quality control to highlight your attention to detail and dedication to producing high-quality castings.

- Use keywords related to the job title and industry, such as ‘iron molding,’ ‘foundry efficiency,’ and ‘casting inspection’ to optimize your resume for search engines.

Essential Experience Highlights for a Strong Iron Molder Helper Resume

- Assisted in the preparation and pouring of molds to produce high-quality iron castings.

- Maintained a clean and slag-free casting area to prevent iron contamination.

- Operated molding machines to create molds according to specifications.

- Inspected castings for defects and ensured they met quality standards.

- Repaired mold cracks and other defects to minimize casting rejections.

- Provided training to new employees on proper mold preparation and pouring techniques.

- Troubleshooted and resolved issues to optimize casting processes and improve efficiency.

Frequently Asked Questions (FAQ’s) For Iron Molder Helper

What are the key responsibilities of an Iron Molder Helper?

The primary responsibilities of an Iron Molder Helper include assisting in mold preparation and pouring, maintaining a clean and safe casting area, operating molding machines, inspecting castings for defects, repairing mold defects, and providing training to new employees.

What qualifications are required to become an Iron Molder Helper?

While formal education is not always required, many Iron Molder Helpers have an Associate’s Degree in Manufacturing Technology or a related field. Prior experience in a foundry or manufacturing environment is also beneficial.

What are the career prospects for an Iron Molder Helper?

With experience and additional training, Iron Molder Helpers can advance to become Iron Molders, Foundry Supervisors, or Quality Control Inspectors. They may also specialize in specific areas of foundry operations, such as pattern making or core making.

What is the work environment of an Iron Molder Helper like?

Iron Molder Helpers typically work in foundries, which can be hot, noisy, and dusty environments. They may also work with heavy equipment and molten metal, so safety precautions must be followed.

What are the key skills and abilities required for an Iron Molder Helper?

Successful Iron Molder Helpers possess strong physical strength and stamina, as well as good hand-eye coordination and attention to detail. They should also have basic math and measurement skills, and be able to follow instructions carefully.

How can I improve my chances of getting hired as an Iron Molder Helper?

To increase your chances of getting hired, highlight your experience and skills in pattern reading, sand handling, and molding machine operation. Emphasize your commitment to safety and quality control, and be prepared to demonstrate your physical strength and stamina.

What is the average salary for an Iron Molder Helper?

According to Indeed, the average salary for an Iron Molder Helper in the United States is around $25 per hour.

What are the benefits of working as an Iron Molder Helper?

Working as an Iron Molder Helper can provide opportunities for job security, competitive wages, and career advancement. It also offers the satisfaction of working in a skilled trade and contributing to the production of high-quality castings.