Are you a seasoned Ironmolder seeking a new career path? Discover our professionally built Ironmolder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

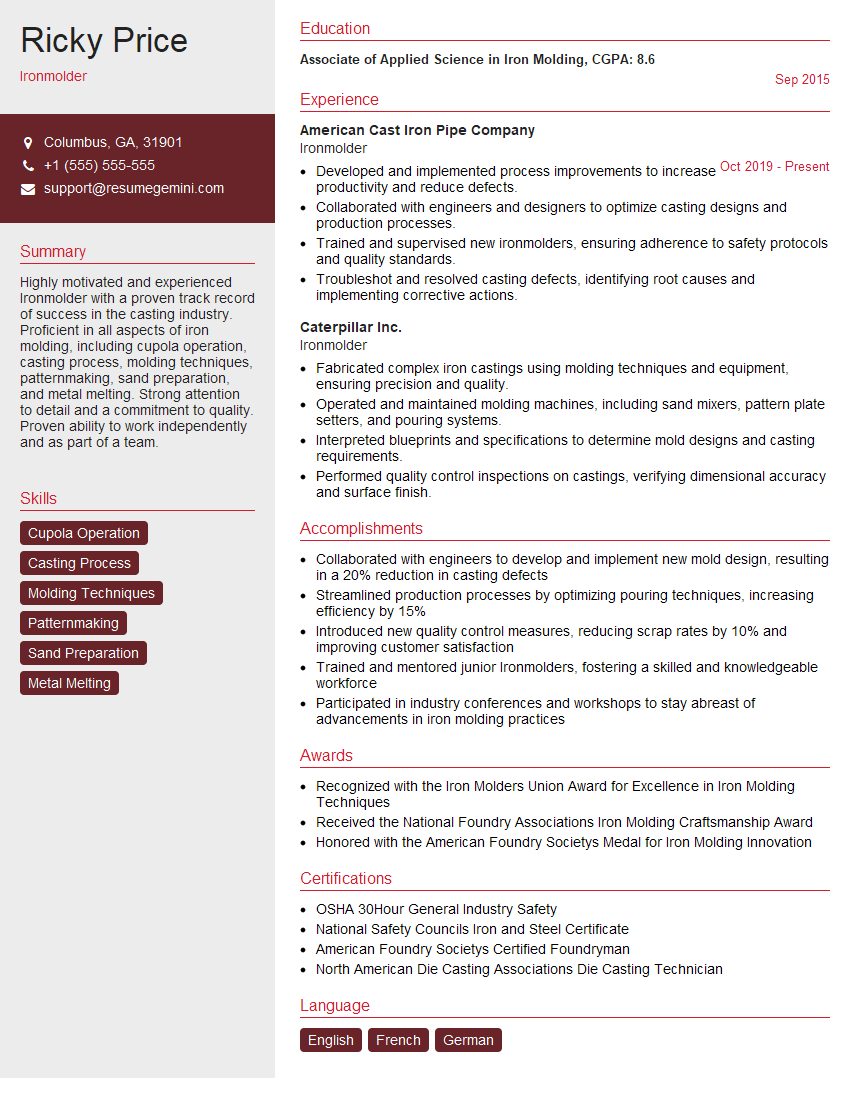

Ricky Price

Ironmolder

Summary

Highly motivated and experienced Ironmolder with a proven track record of success in the casting industry. Proficient in all aspects of iron molding, including cupola operation, casting process, molding techniques, patternmaking, sand preparation, and metal melting. Strong attention to detail and a commitment to quality. Proven ability to work independently and as part of a team.

Education

Associate of Applied Science in Iron Molding

September 2015

Skills

- Cupola Operation

- Casting Process

- Molding Techniques

- Patternmaking

- Sand Preparation

- Metal Melting

Work Experience

Ironmolder

- Developed and implemented process improvements to increase productivity and reduce defects.

- Collaborated with engineers and designers to optimize casting designs and production processes.

- Trained and supervised new ironmolders, ensuring adherence to safety protocols and quality standards.

- Troubleshot and resolved casting defects, identifying root causes and implementing corrective actions.

Ironmolder

- Fabricated complex iron castings using molding techniques and equipment, ensuring precision and quality.

- Operated and maintained molding machines, including sand mixers, pattern plate setters, and pouring systems.

- Interpreted blueprints and specifications to determine mold designs and casting requirements.

- Performed quality control inspections on castings, verifying dimensional accuracy and surface finish.

Accomplishments

- Collaborated with engineers to develop and implement new mold design, resulting in a 20% reduction in casting defects

- Streamlined production processes by optimizing pouring techniques, increasing efficiency by 15%

- Introduced new quality control measures, reducing scrap rates by 10% and improving customer satisfaction

- Trained and mentored junior Ironmolders, fostering a skilled and knowledgeable workforce

- Participated in industry conferences and workshops to stay abreast of advancements in iron molding practices

Awards

- Recognized with the Iron Molders Union Award for Excellence in Iron Molding Techniques

- Received the National Foundry Associations Iron Molding Craftsmanship Award

- Honored with the American Foundry Societys Medal for Iron Molding Innovation

Certificates

- OSHA 30Hour General Industry Safety

- National Safety Councils Iron and Steel Certificate

- American Foundry Societys Certified Foundryman

- North American Die Casting Associations Die Casting Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ironmolder

- Highlight your experience in cupola operation and metal melting.

- Showcase your knowledge of molding techniques and patternmaking.

- Emphasize your attention to detail and commitment to quality.

- Include any certifications or training you have received in iron molding.

- Demonstrate your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Ironmolder Resume

- Operate cupola furnaces to melt iron and maintain optimal temperatures.

- Prepare and maintain sand molds and cores for casting.

- Cast molten iron into molds and ensure proper cooling and solidification.

- Inspect castings for defects and make necessary adjustments to molding and casting processes.

- Maintain and repair molding equipment, including patterns, flasks, and core boxes.

- Adhere to safety regulations and ensure a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Ironmolder

What is the primary role of an Ironmolder?

An Ironmolder is responsible for producing iron castings by melting iron in a cupola furnace, preparing molds and cores, casting molten iron into molds, and inspecting castings for defects.

What skills are required to be a successful Ironmolder?

Successful Ironmolders typically possess strong technical skills in cupola operation, casting process, molding techniques, patternmaking, sand preparation, and metal melting. Additionally, they have a keen eye for detail, are committed to quality, and are able to work independently and as part of a team.

What are the career prospects for Ironmolders?

Ironmolders are in high demand in the manufacturing industry. With experience, they can advance to supervisory roles or specialize in specific areas of iron molding, such as patternmaking or casting design.

What is the average salary for Ironmolders?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Ironmolders was $51,320 as of May 2021.

What are the working conditions for Ironmolders?

Ironmolders typically work in foundries, which can be hot, noisy, and dusty. They may also work with hazardous materials, such as molten iron and chemicals.

What is the job outlook for Ironmolders?

The job outlook for Ironmolders is expected to be good over the next decade, as there will be a growing demand for iron castings in the automotive, construction, and other industries.