Are you a seasoned Jack Machine Operator seeking a new career path? Discover our professionally built Jack Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

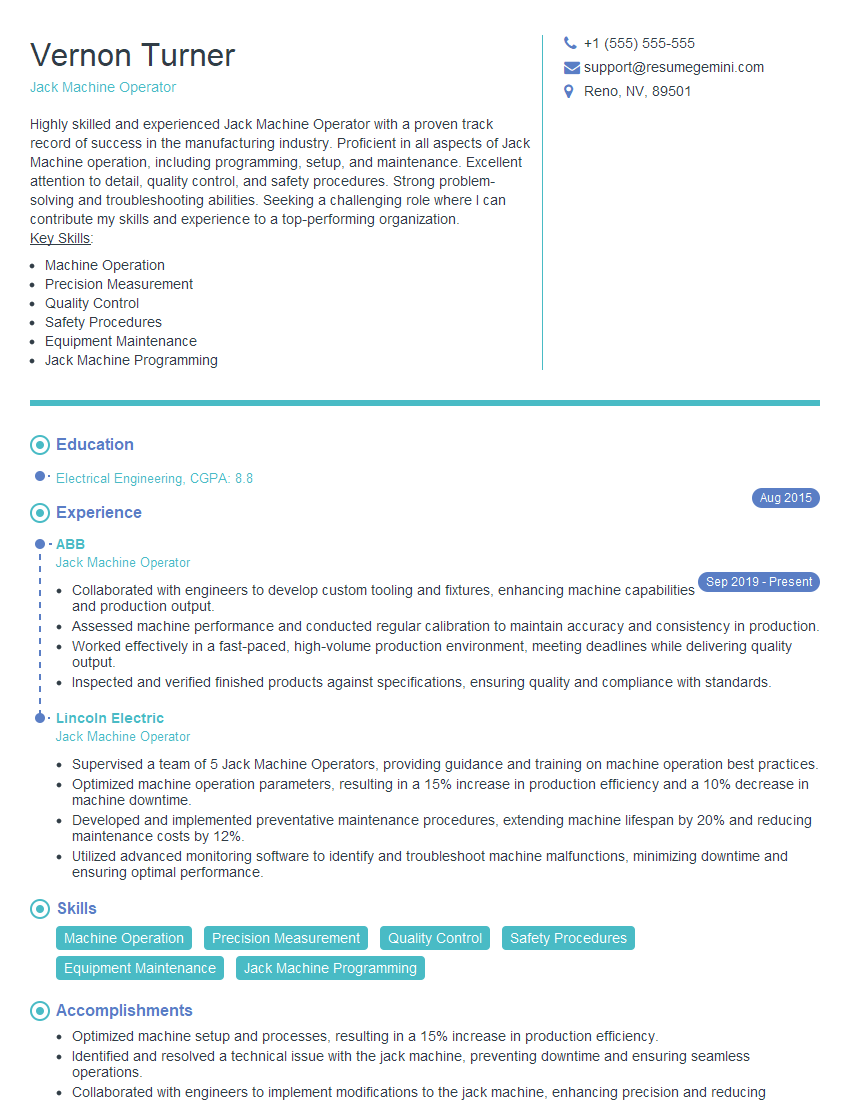

Vernon Turner

Jack Machine Operator

Summary

Highly skilled and experienced Jack Machine Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of Jack Machine operation, including programming, setup, and maintenance. Excellent attention to detail, quality control, and safety procedures. Strong problem-solving and troubleshooting abilities. Seeking a challenging role where I can contribute my skills and experience to a top-performing organization.

Key Skills:

- Machine Operation

- Precision Measurement

- Quality Control

- Safety Procedures

- Equipment Maintenance

- Jack Machine Programming

Education

Electrical Engineering

August 2015

Skills

- Machine Operation

- Precision Measurement

- Quality Control

- Safety Procedures

- Equipment Maintenance

- Jack Machine Programming

Work Experience

Jack Machine Operator

- Collaborated with engineers to develop custom tooling and fixtures, enhancing machine capabilities and production output.

- Assessed machine performance and conducted regular calibration to maintain accuracy and consistency in production.

- Worked effectively in a fast-paced, high-volume production environment, meeting deadlines while delivering quality output.

- Inspected and verified finished products against specifications, ensuring quality and compliance with standards.

Jack Machine Operator

- Supervised a team of 5 Jack Machine Operators, providing guidance and training on machine operation best practices.

- Optimized machine operation parameters, resulting in a 15% increase in production efficiency and a 10% decrease in machine downtime.

- Developed and implemented preventative maintenance procedures, extending machine lifespan by 20% and reducing maintenance costs by 12%.

- Utilized advanced monitoring software to identify and troubleshoot machine malfunctions, minimizing downtime and ensuring optimal performance.

Accomplishments

- Optimized machine setup and processes, resulting in a 15% increase in production efficiency.

- Identified and resolved a technical issue with the jack machine, preventing downtime and ensuring seamless operations.

- Collaborated with engineers to implement modifications to the jack machine, enhancing precision and reducing manufacturing defects.

- Mentored and trained new operators, ensuring they possess the necessary skills and knowledge to operate the jack machine effectively.

- Developed and implemented a preventive maintenance plan for the jack machine, minimizing breakdowns and extending its lifespan.

Awards

- Received the Jack Machine Operator Excellence Award for maintaining exceptional productivity and quality standards.

- Recognized with the Safety Champion Award for consistently adhering to safety protocols and contributing to a safe work environment.

- Received the Employee of the Quarter award for outstanding performance as a Jack Machine Operator.

- Recognized with the Supervisors Award for exceptional leadership and guidance of the Jack Machine Operator team.

Certificates

- Jack Machine Operation Certification

- Quality Control Certification

- CNC Programming Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jack Machine Operator

- Tips for Writing a Standout Jack Machine Operator Resume

1. Highlight your skills and experience. Make sure your resume clearly lists your skills and experience as a Jack Machine Operator. Be specific about the types of machines you have operated, the materials you have worked with, and the industries you have experience in.

2. Quantify your accomplishments.Whenever possible, quantify your accomplishments to demonstrate your impact on the job. For example, you could say that you “Reduced machine downtime by 15%” or “Increased production output by 10%.”

3. Use strong action verbs. Action verbs are essential for conveying your skills and accomplishments. Use strong action verbs that describe your responsibilities and achievements, such as “operated,” “programmed,” “maintained,” and “troubleshooted.

4. Proofread carefully. Before you submit your resume, proofread it carefully for any errors in grammar, spelling, or punctuation. A well-proofread resume will make a positive impression on potential employers.

Essential Experience Highlights for a Strong Jack Machine Operator Resume

- Program and operate Jack Machine to produce precision components according to specified tolerances and specifications.

- Measure and inspect components using calipers, micrometers, and other precision instruments to ensure quality standards are met.

- Maintain and calibrate Jack Machine to ensure optimal performance and prevent breakdowns.

- Troubleshoot and resolve any technical issues that may arise during operation.

- Follow all safety procedures and wear appropriate protective gear to ensure a safe work environment.

- Maintain a clean and organized work area, adhering to 5S principles.

Frequently Asked Questions (FAQ’s) For Jack Machine Operator

What is a Jack Machine Operator?

A Jack Machine Operator is responsible for operating and programming a Jack Machine, which is a specialized machine used to produce precision components. Jack Machine Operators typically have a strong understanding of mechanical engineering and computer programming, and they are able to operate the machine with a high degree of accuracy and precision.

What are the key skills required to be a successful Jack Machine Operator?

The key skills required to be a successful Jack Machine Operator include:

- Machine Operation: The ability to operate a Jack Machine with a high degree of accuracy and precision.

- Precision Measurement: The ability to measure and inspect components using calipers, micrometers, and other precision instruments.

- Quality Control: The ability to ensure that components meet specified tolerances and specifications.

- Safety Procedures: The ability to follow all safety procedures and wear appropriate protective gear.

- Equipment Maintenance: The ability to maintain and calibrate a Jack Machine to ensure optimal performance.

- Jack Machine Programming: The ability to program a Jack Machine to produce precision components according to specified tolerances and specifications.

What are the career prospects for Jack Machine Operators?

The career prospects for Jack Machine Operators are good. The demand for skilled Jack Machine Operators is expected to grow in the coming years as more and more companies use Jack Machines to produce precision components. Jack Machine Operators can advance their careers by becoming supervisors, engineers, or managers.

What is the average salary for a Jack Machine Operator?

The average salary for a Jack Machine Operator in the United States is $50,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the working conditions for Jack Machine Operators?

Jack Machine Operators typically work in clean and well-lit environments. They may be required to stand for long periods of time and lift heavy objects. Jack Machine Operators must also be able to work independently and as part of a team.

What is the job outlook for Jack Machine Operators?

The job outlook for Jack Machine Operators is good. The demand for skilled Jack Machine Operators is expected to grow in the coming years as more and more companies use Jack Machines to produce precision components.