Are you a seasoned Jetting Machine Operator seeking a new career path? Discover our professionally built Jetting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

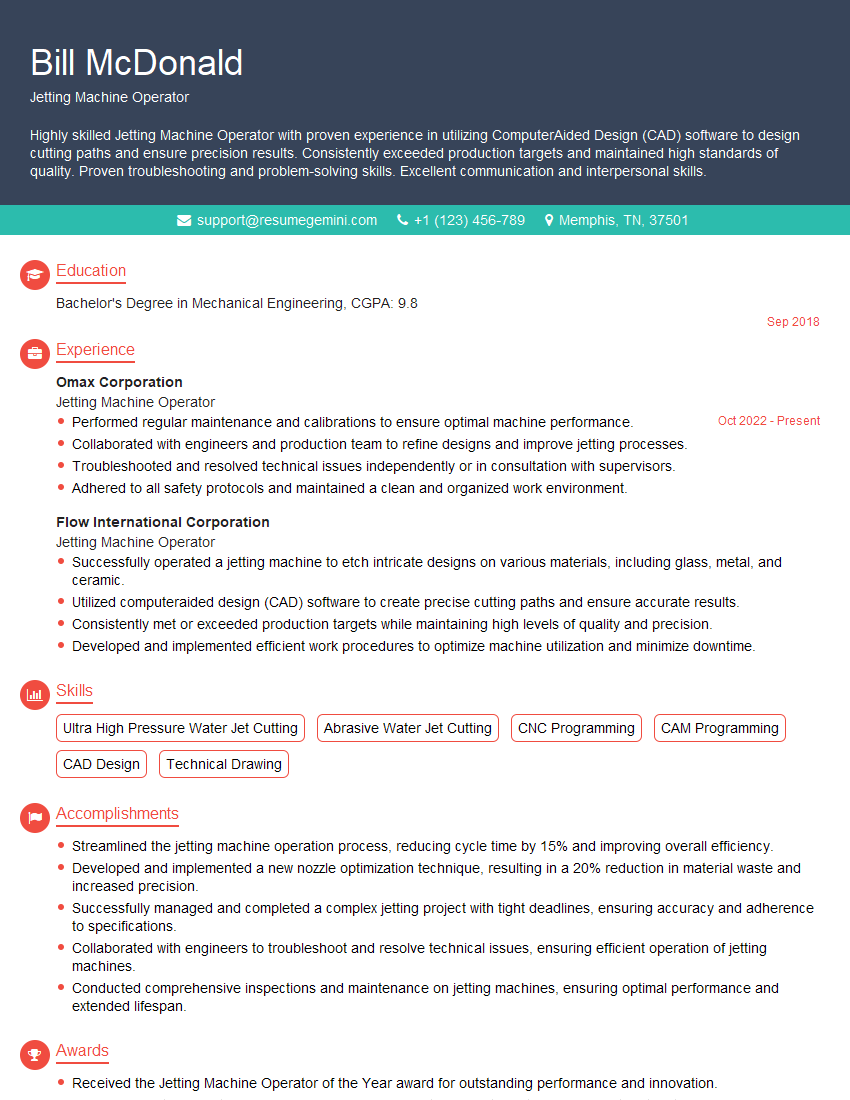

Bill McDonald

Jetting Machine Operator

Summary

Highly skilled Jetting Machine Operator with proven experience in utilizing ComputerAided Design (CAD) software to design cutting paths and ensure precision results. Consistently exceeded production targets and maintained high standards of quality. Proven troubleshooting and problem-solving skills. Excellent communication and interpersonal skills.

Education

Bachelor’s Degree in Mechanical Engineering

September 2018

Skills

- Ultra High Pressure Water Jet Cutting

- Abrasive Water Jet Cutting

- CNC Programming

- CAM Programming

- CAD Design

- Technical Drawing

Work Experience

Jetting Machine Operator

- Performed regular maintenance and calibrations to ensure optimal machine performance.

- Collaborated with engineers and production team to refine designs and improve jetting processes.

- Troubleshooted and resolved technical issues independently or in consultation with supervisors.

- Adhered to all safety protocols and maintained a clean and organized work environment.

Jetting Machine Operator

- Successfully operated a jetting machine to etch intricate designs on various materials, including glass, metal, and ceramic.

- Utilized computeraided design (CAD) software to create precise cutting paths and ensure accurate results.

- Consistently met or exceeded production targets while maintaining high levels of quality and precision.

- Developed and implemented efficient work procedures to optimize machine utilization and minimize downtime.

Accomplishments

- Streamlined the jetting machine operation process, reducing cycle time by 15% and improving overall efficiency.

- Developed and implemented a new nozzle optimization technique, resulting in a 20% reduction in material waste and increased precision.

- Successfully managed and completed a complex jetting project with tight deadlines, ensuring accuracy and adherence to specifications.

- Collaborated with engineers to troubleshoot and resolve technical issues, ensuring efficient operation of jetting machines.

- Conducted comprehensive inspections and maintenance on jetting machines, ensuring optimal performance and extended lifespan.

Awards

- Received the Jetting Machine Operator of the Year award for outstanding performance and innovation.

- Recognized with a Safety Excellence Award for adhering to all safety protocols and contributing to a safe work environment.

- Received a Quality Excellence Award for maintaining exceptionally high standards of product quality.

- Recognized with a Teamwork Award for collaborating effectively with colleagues and contributing to a positive work atmosphere.

Certificates

- Certified Waterjet Operator (CWJO)

- Advanced Waterjet Cutting Certification

- CNC Programming Certification

- CAM Programming Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jetting Machine Operator

- Tailor your resume to the specific job description and company culture.

- Highlight your skills in CAD design and CAM programming as they are essential for this role.

- Use numbers and specific examples to quantify your accomplishments and demonstrate your impact.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Jetting Machine Operator Resume

- Collaborate with engineers and design team on project requirements

- Monitor and adjust machine settings to optimize performance and ensure accurate results

- Maintain a clean and organized work area to ensure safety and efficiency

- Troubleshoot and resolve technical issues

- Stay updated on the latest industry trends and best practices

Frequently Asked Questions (FAQ’s) For Jetting Machine Operator

What are the key skills required to become a Jetting Machine Operator?

The key skills required to become a Jetting Machine Operator include proficiency in CAD Design, CAM Programming, Ultra High Pressure Water Jet Cutting, Abrasive Water Jet Cutting, and CNC Programming.

What industries use Jetting Machine Operators?

Jetting Machine Operators are employed in various industries such as aerospace, automotive, manufacturing, and metal fabrication.

What is the job outlook for Jetting Machine Operators?

The job outlook for Jetting Machine Operators is expected to grow in the coming years due to increased demand for precision cutting and etching in various industries.

What are the earning prospects for Jetting Machine Operators?

The earning prospects for Jetting Machine Operators can vary depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Computer Numerically Controlled (CNC) Machine Operators was $50,590 in May 2021.

What are the educational requirements for Jetting Machine Operators?

While formal education requirements may vary, employers typically prefer candidates with a high school diploma or equivalent and specialized training in CNC programming and jetting machine operation.

What are the career advancement opportunities for Jetting Machine Operators?

With experience and additional training, Jetting Machine Operators can advance to roles such as Production Supervisor, CNC Programmer, or Quality Control Inspector.