Are you a seasoned Jewel Flat Surfacer seeking a new career path? Discover our professionally built Jewel Flat Surfacer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

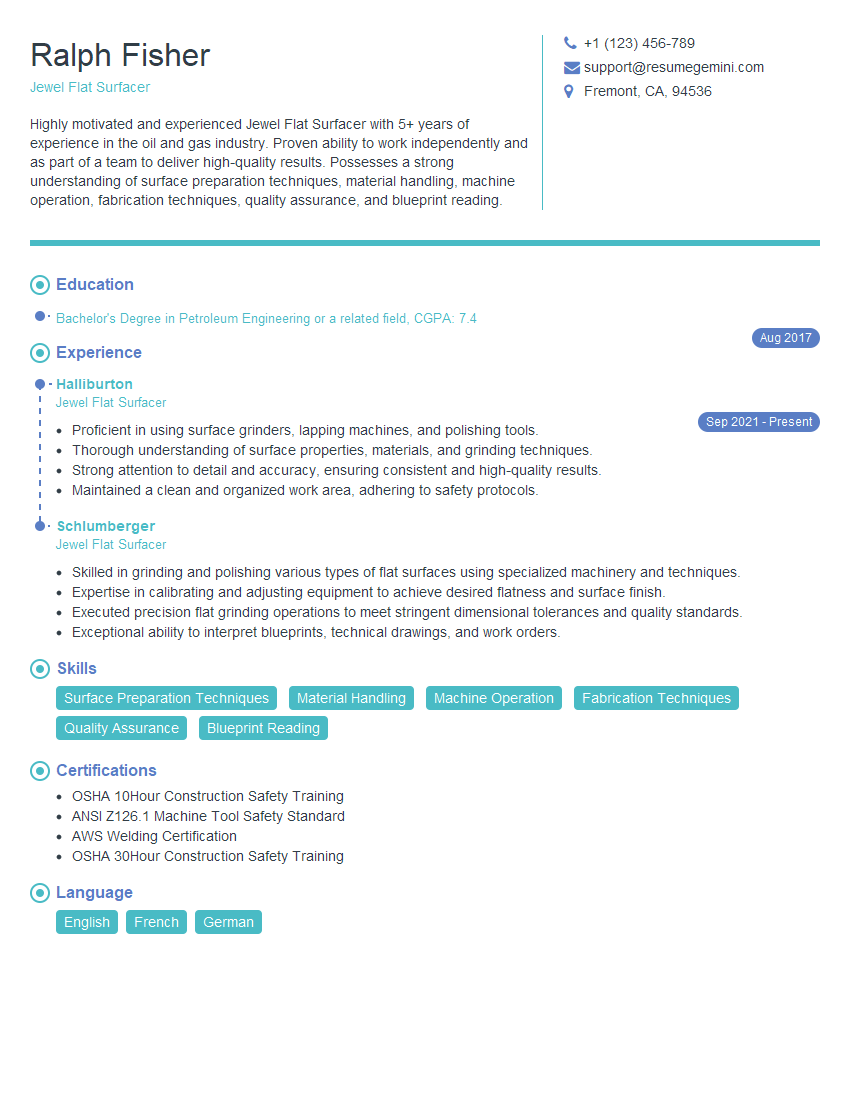

Ralph Fisher

Jewel Flat Surfacer

Summary

Highly motivated and experienced Jewel Flat Surfacer with 5+ years of experience in the oil and gas industry. Proven ability to work independently and as part of a team to deliver high-quality results. Possesses a strong understanding of surface preparation techniques, material handling, machine operation, fabrication techniques, quality assurance, and blueprint reading.

Education

Bachelor’s Degree in Petroleum Engineering or a related field

August 2017

Skills

- Surface Preparation Techniques

- Material Handling

- Machine Operation

- Fabrication Techniques

- Quality Assurance

- Blueprint Reading

Work Experience

Jewel Flat Surfacer

- Proficient in using surface grinders, lapping machines, and polishing tools.

- Thorough understanding of surface properties, materials, and grinding techniques.

- Strong attention to detail and accuracy, ensuring consistent and high-quality results.

- Maintained a clean and organized work area, adhering to safety protocols.

Jewel Flat Surfacer

- Skilled in grinding and polishing various types of flat surfaces using specialized machinery and techniques.

- Expertise in calibrating and adjusting equipment to achieve desired flatness and surface finish.

- Executed precision flat grinding operations to meet stringent dimensional tolerances and quality standards.

- Exceptional ability to interpret blueprints, technical drawings, and work orders.

Certificates

- OSHA 10Hour Construction Safety Training

- ANSI Z126.1 Machine Tool Safety Standard

- AWS Welding Certification

- OSHA 30Hour Construction Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jewel Flat Surfacer

- Use strong action verbs: When describing your experience, use strong action verbs that highlight your skills and accomplishments.

- Quantify your results: Whenever possible, quantify your results to demonstrate the impact of your work.

- Highlight your skills: Make sure to highlight your skills in surface preparation techniques, material handling, machine operation, fabrication techniques, quality assurance, and blueprint reading.

- Proofread your resume: Before you submit your resume, proofread it carefully for any errors.

Essential Experience Highlights for a Strong Jewel Flat Surfacer Resume

- Prepare and clean surfaces for application of coatings and laminates

- Apply coatings and laminates to surfaces using a variety of techniques

- Inspect and test surfaces to ensure they meet specifications

- Maintain and calibrate equipment used in the surfacing process

- Supervise and train other jewel flat surfacers

- Develop and implement new surface preparation and application techniques

- Troubleshoot and resolve problems that arise during the surfacing process

Frequently Asked Questions (FAQ’s) For Jewel Flat Surfacer

What is a jewel flat surfacer?

A jewel flat surfacer is a person who prepares and finishes surfaces for the application of coatings and laminates.

What are the different types of surface preparation techniques?

There are a variety of surface preparation techniques, including sanding, grinding, and blasting.

What are the different types of coatings and laminates?

There are a variety of coatings and laminates, including paints, epoxies, and vinyls.

What are the different types of machines used in the surfacing process?

There are a variety of machines used in the surfacing process, including sanders, grinders, and spray guns.

What are the different quality assurance procedures used in the surfacing process?

There are a variety of quality assurance procedures used in the surfacing process, including visual inspection, testing, and documentation.

What are the career opportunities for jewel flat surfacers?

Jewel flat surfacers can work in a variety of industries, including manufacturing, construction, and transportation.