Are you a seasoned Jig and Fixture Repairer seeking a new career path? Discover our professionally built Jig and Fixture Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

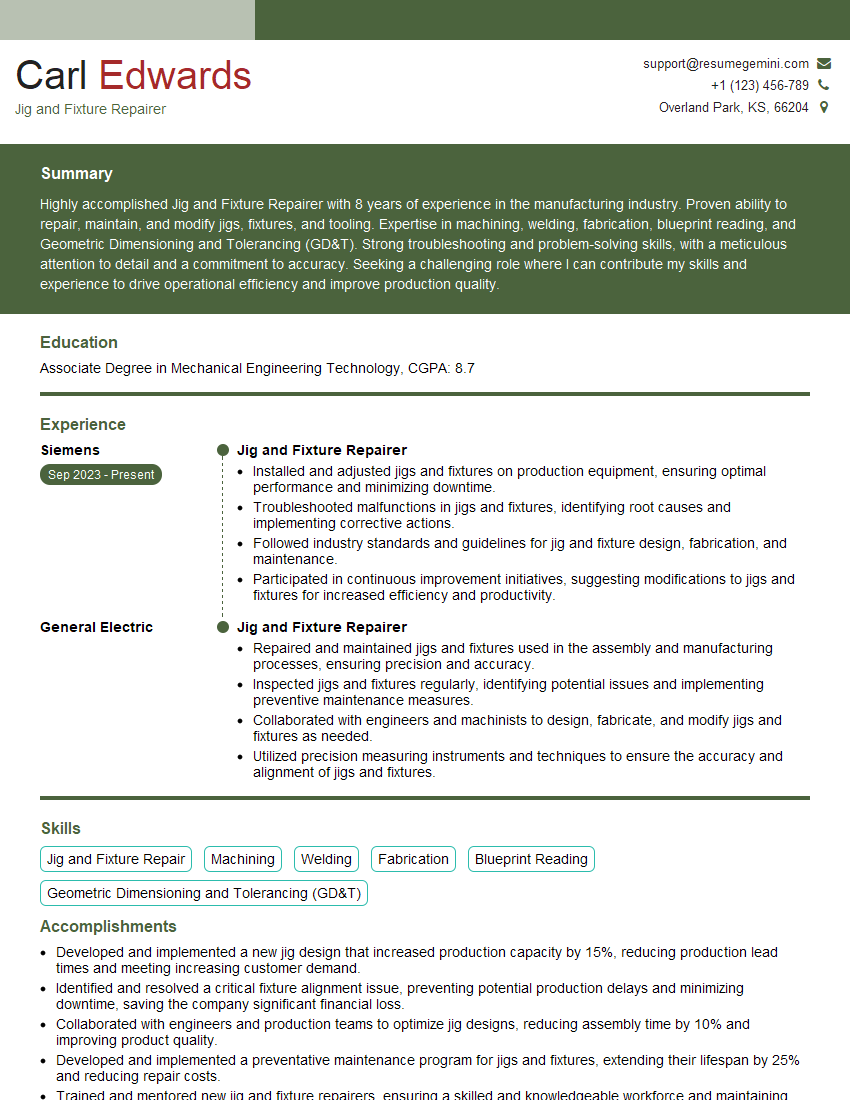

Carl Edwards

Jig and Fixture Repairer

Summary

Highly accomplished Jig and Fixture Repairer with 8 years of experience in the manufacturing industry. Proven ability to repair, maintain, and modify jigs, fixtures, and tooling. Expertise in machining, welding, fabrication, blueprint reading, and Geometric Dimensioning and Tolerancing (GD&T). Strong troubleshooting and problem-solving skills, with a meticulous attention to detail and a commitment to accuracy. Seeking a challenging role where I can contribute my skills and experience to drive operational efficiency and improve production quality.

Education

Associate Degree in Mechanical Engineering Technology

August 2019

Skills

- Jig and Fixture Repair

- Machining

- Welding

- Fabrication

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Jig and Fixture Repairer

- Installed and adjusted jigs and fixtures on production equipment, ensuring optimal performance and minimizing downtime.

- Troubleshooted malfunctions in jigs and fixtures, identifying root causes and implementing corrective actions.

- Followed industry standards and guidelines for jig and fixture design, fabrication, and maintenance.

- Participated in continuous improvement initiatives, suggesting modifications to jigs and fixtures for increased efficiency and productivity.

Jig and Fixture Repairer

- Repaired and maintained jigs and fixtures used in the assembly and manufacturing processes, ensuring precision and accuracy.

- Inspected jigs and fixtures regularly, identifying potential issues and implementing preventive maintenance measures.

- Collaborated with engineers and machinists to design, fabricate, and modify jigs and fixtures as needed.

- Utilized precision measuring instruments and techniques to ensure the accuracy and alignment of jigs and fixtures.

Accomplishments

- Developed and implemented a new jig design that increased production capacity by 15%, reducing production lead times and meeting increasing customer demand.

- Identified and resolved a critical fixture alignment issue, preventing potential production delays and minimizing downtime, saving the company significant financial loss.

- Collaborated with engineers and production teams to optimize jig designs, reducing assembly time by 10% and improving product quality.

- Developed and implemented a preventative maintenance program for jigs and fixtures, extending their lifespan by 25% and reducing repair costs.

- Trained and mentored new jig and fixture repairers, ensuring a skilled and knowledgeable workforce and maintaining highquality repair standards.

Awards

- Recognized for outstanding contributions to the development and implementation of innovative jig and fixture solutions, resulting in improved production efficiency and reduced downtime.

- Awarded Jig and Fixture Repairer of the Year for exceptional performance in troubleshooting and repairing complex fixtures, ensuring optimal production line operations.

- Received Safety Excellence Award for implementing innovative safety measures that significantly reduced hazards in the jig and fixture repair workshop.

Certificates

- Certified Jig and Fixture Builder (CJFB)

- Certified Welding Inspector (CWI)

- Certified Six Sigma Green Belt

- Certified Lean Manufacturing Professional

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jig and Fixture Repairer

- Highlight your technical skills and experience in jig and fixture repair, including specific tools and techniques.

- Showcase your knowledge of GD&T and its application in the manufacturing process.

- Provide examples of troubleshooting and problem-solving scenarios that demonstrate your critical thinking abilities.

- Emphasize your commitment to safety, accuracy, and attention to detail.

Essential Experience Highlights for a Strong Jig and Fixture Repairer Resume

- Repair and maintain jigs, fixtures, and tooling to ensure optimal performance and accuracy

- Diagnose and troubleshoot malfunctions, identify root causes, and implement effective solutions

- Follow blueprints and GD&T specifications to design and fabricate new jigs and fixtures

- Collaborate with engineers and production teams to identify areas for improvement and optimize tooling

- Manage inventory of spare parts and consumables, ensuring timely availability of resources

- Maintain a clean and organized work area, adhering to safety regulations and best practices

Frequently Asked Questions (FAQ’s) For Jig and Fixture Repairer

What is the primary role of a Jig and Fixture Repairer?

The primary role of a Jig and Fixture Repairer is to maintain, repair, and modify jigs, fixtures, and tooling used in the manufacturing process. This involves diagnosing malfunctions, troubleshooting issues, and implementing solutions to ensure optimal performance and accuracy.

What are the essential skills required for this role?

Essential skills for a Jig and Fixture Repairer include machining, welding, fabrication, blueprint reading, GD&T, and strong troubleshooting and problem-solving abilities. Attention to detail and commitment to accuracy are also crucial.

What industries employ Jig and Fixture Repairers?

Jig and Fixture Repairers are employed in various industries, including automotive, aerospace, manufacturing, and construction. They play a vital role in maintaining and repairing the tools and equipment used in these industries.

What are the career prospects for a Jig and Fixture Repairer?

With experience and skill development, Jig and Fixture Repairers can advance to roles such as Tool and Die Maker, Maintenance Supervisor, or Manufacturing Engineer. They can also specialize in specific areas of jig and fixture repair, such as welding or GD&T.

What is the typical work environment for a Jig and Fixture Repairer?

Jig and Fixture Repairers typically work in manufacturing facilities, workshops, or maintenance departments. They may work independently or as part of a team, and the work environment can be noisy and involve exposure to machinery and tools.

What are the safety precautions that a Jig and Fixture Repairer should observe?

Jig and Fixture Repairers should always wear appropriate safety gear, including eye protection, gloves, and hearing protection. They should also follow established safety procedures, be aware of potential hazards, and operate machinery and equipment safely.