Are you a seasoned Jig Fitter seeking a new career path? Discover our professionally built Jig Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

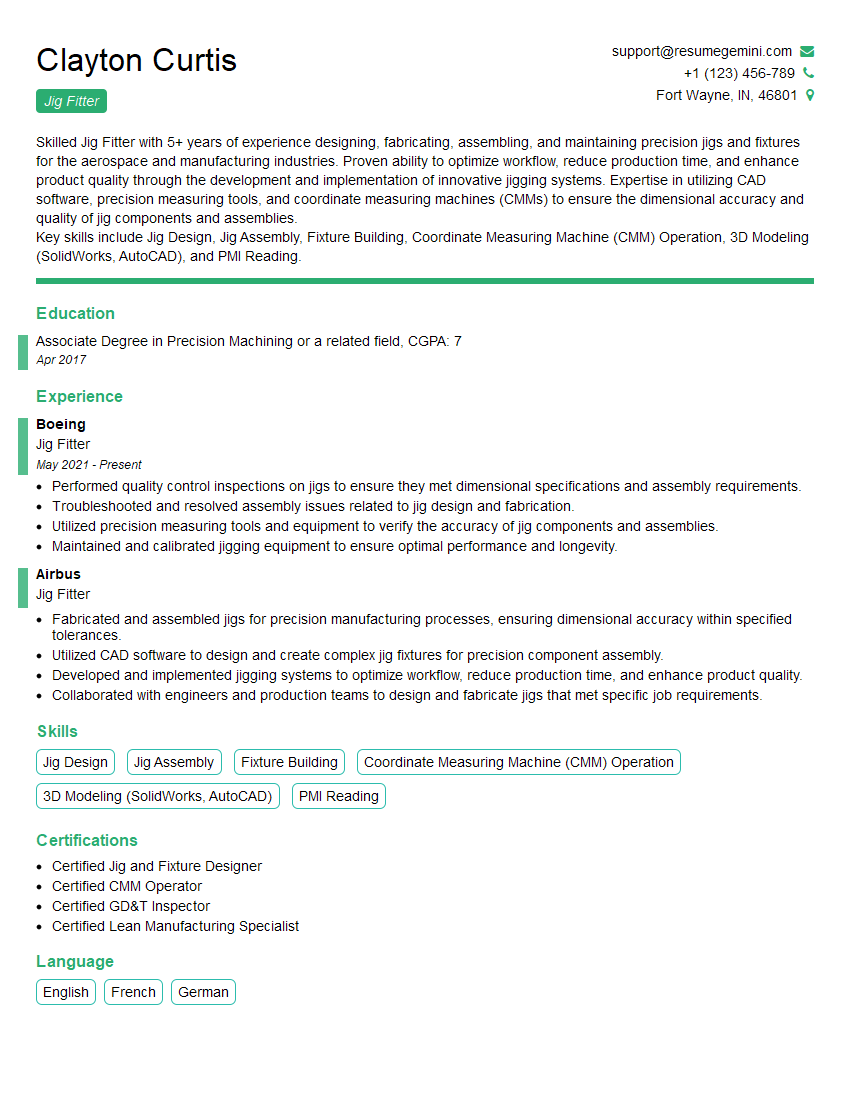

Clayton Curtis

Jig Fitter

Summary

Skilled Jig Fitter with 5+ years of experience designing, fabricating, assembling, and maintaining precision jigs and fixtures for the aerospace and manufacturing industries. Proven ability to optimize workflow, reduce production time, and enhance product quality through the development and implementation of innovative jigging systems. Expertise in utilizing CAD software, precision measuring tools, and coordinate measuring machines (CMMs) to ensure the dimensional accuracy and quality of jig components and assemblies.

Key skills include Jig Design, Jig Assembly, Fixture Building, Coordinate Measuring Machine (CMM) Operation, 3D Modeling (SolidWorks, AutoCAD), and PMI Reading.

Education

Associate Degree in Precision Machining or a related field

April 2017

Skills

- Jig Design

- Jig Assembly

- Fixture Building

- Coordinate Measuring Machine (CMM) Operation

- 3D Modeling (SolidWorks, AutoCAD)

- PMI Reading

Work Experience

Jig Fitter

- Performed quality control inspections on jigs to ensure they met dimensional specifications and assembly requirements.

- Troubleshooted and resolved assembly issues related to jig design and fabrication.

- Utilized precision measuring tools and equipment to verify the accuracy of jig components and assemblies.

- Maintained and calibrated jigging equipment to ensure optimal performance and longevity.

Jig Fitter

- Fabricated and assembled jigs for precision manufacturing processes, ensuring dimensional accuracy within specified tolerances.

- Utilized CAD software to design and create complex jig fixtures for precision component assembly.

- Developed and implemented jigging systems to optimize workflow, reduce production time, and enhance product quality.

- Collaborated with engineers and production teams to design and fabricate jigs that met specific job requirements.

Certificates

- Certified Jig and Fixture Designer

- Certified CMM Operator

- Certified GD&T Inspector

- Certified Lean Manufacturing Specialist

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jig Fitter

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous projects.

- Highlight your skills in jig design, fabrication, and assembly, as well as your knowledge of CAD software and precision measuring equipment.

- Showcase your problem-solving skills and ability to troubleshoot and resolve assembly issues.

- Demonstrate your understanding of quality control procedures and your commitment to maintaining the accuracy and reliability of jigs and fixtures.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Jig Fitter Resume

- Designed and created complex jig fixtures for precision component assembly using CAD software.

- Fabricated and assembled jigs to meet specified dimensional tolerances.

- Developed and implemented jigging systems to optimize workflow, reduce production time, and enhance product quality.

- Collaborated with engineers and production teams to design and fabricate jigs that met specific job requirements.

- Performed quality control inspections on jigs to ensure they met dimensional specifications and assembly requirements.

- Troubleshooted and resolved assembly issues related to jig design and fabrication.

- Utilized precision measuring tools and equipment to verify the accuracy of jig components and assemblies.

Frequently Asked Questions (FAQ’s) For Jig Fitter

What is a Jig Fitter?

A Jig Fitter is a skilled technician responsible for designing, fabricating, assembling, and maintaining jigs and fixtures used in precision manufacturing processes.

What are the primary responsibilities of a Jig Fitter?

The primary responsibilities of a Jig Fitter include designing jigs and fixtures using CAD software, fabricating and assembling jigs to meet specified tolerances, implementing jigging systems to optimize workflow and enhance product quality, and performing quality control inspections to ensure the accuracy and reliability of jigs and fixtures.

What skills are required to be a successful Jig Fitter?

Successful Jig Fitters typically possess strong skills in jig design, jig assembly, fixture building, coordinate measuring machine (CMM) operation, 3D modeling (SolidWorks, AutoCAD), and PMI reading.

What are the career prospects for Jig Fitters?

Jig Fitters can advance their careers by specializing in specific areas such as aerospace, automotive, or medical device manufacturing. They can also move into supervisory or management roles, or pursue further education to become engineers or designers.

What is the job outlook for Jig Fitters?

The job outlook for Jig Fitters is expected to be good over the next few years, driven by the increasing demand for precision manufacturing in various industries.

What are the average salary expectations for Jig Fitters?

The average salary for Jig Fitters can vary depending on experience, location, and industry, but typically ranges from $25,000 to $60,000 per year.

What are the most important qualities for a Jig Fitter?

The most important qualities for a Jig Fitter include attention to detail, precision, problem-solving skills, and the ability to work independently and as part of a team.