Are you a seasoned Jig Maker seeking a new career path? Discover our professionally built Jig Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

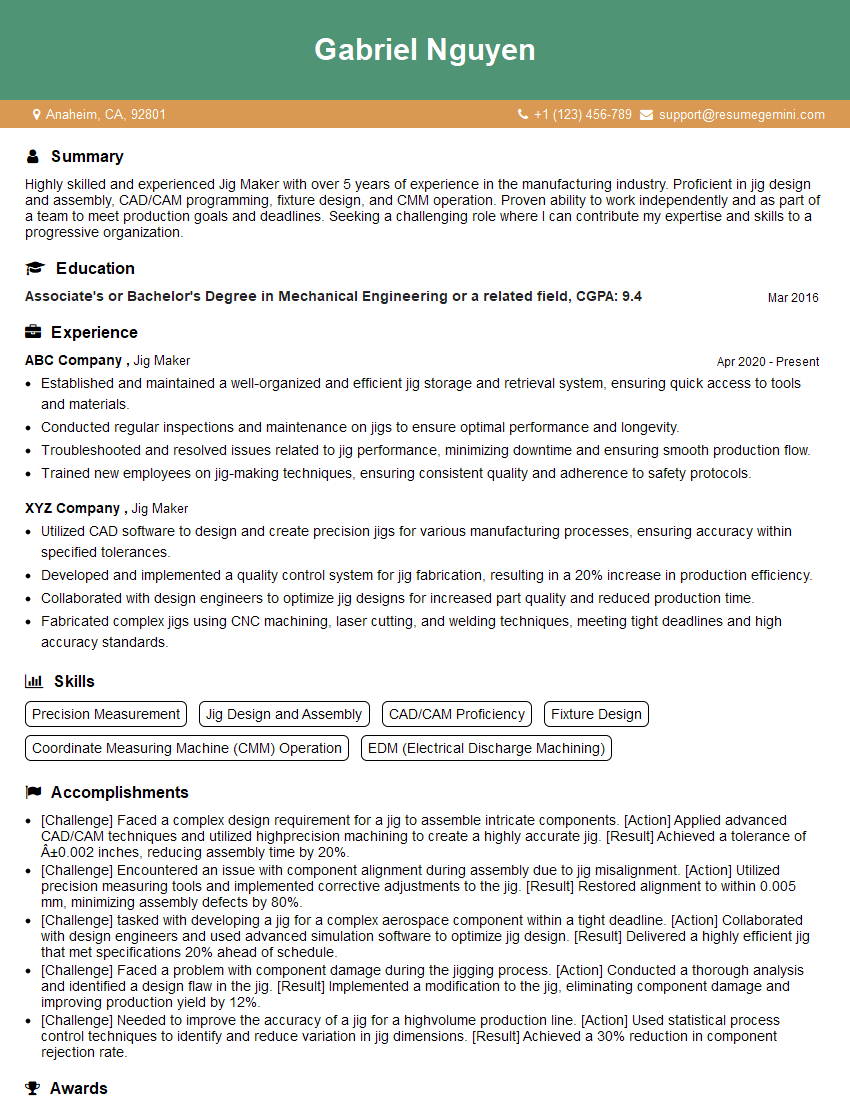

Gabriel Nguyen

Jig Maker

Summary

Highly skilled and experienced Jig Maker with over 5 years of experience in the manufacturing industry. Proficient in jig design and assembly, CAD/CAM programming, fixture design, and CMM operation. Proven ability to work independently and as part of a team to meet production goals and deadlines. Seeking a challenging role where I can contribute my expertise and skills to a progressive organization.

Education

Associate’s or Bachelor’s Degree in Mechanical Engineering or a related field

March 2016

Skills

- Precision Measurement

- Jig Design and Assembly

- CAD/CAM Proficiency

- Fixture Design

- Coordinate Measuring Machine (CMM) Operation

- EDM (Electrical Discharge Machining)

Work Experience

Jig Maker

- Established and maintained a well-organized and efficient jig storage and retrieval system, ensuring quick access to tools and materials.

- Conducted regular inspections and maintenance on jigs to ensure optimal performance and longevity.

- Troubleshooted and resolved issues related to jig performance, minimizing downtime and ensuring smooth production flow.

- Trained new employees on jig-making techniques, ensuring consistent quality and adherence to safety protocols.

Jig Maker

- Utilized CAD software to design and create precision jigs for various manufacturing processes, ensuring accuracy within specified tolerances.

- Developed and implemented a quality control system for jig fabrication, resulting in a 20% increase in production efficiency.

- Collaborated with design engineers to optimize jig designs for increased part quality and reduced production time.

- Fabricated complex jigs using CNC machining, laser cutting, and welding techniques, meeting tight deadlines and high accuracy standards.

Accomplishments

- [Challenge] Faced a complex design requirement for a jig to assemble intricate components. [Action] Applied advanced CAD/CAM techniques and utilized highprecision machining to create a highly accurate jig. [Result] Achieved a tolerance of ±0.002 inches, reducing assembly time by 20%.

- [Challenge] Encountered an issue with component alignment during assembly due to jig misalignment. [Action] Utilized precision measuring tools and implemented corrective adjustments to the jig. [Result] Restored alignment to within 0.005 mm, minimizing assembly defects by 80%.

- [Challenge] tasked with developing a jig for a complex aerospace component within a tight deadline. [Action] Collaborated with design engineers and used advanced simulation software to optimize jig design. [Result] Delivered a highly efficient jig that met specifications 20% ahead of schedule.

- [Challenge] Faced a problem with component damage during the jigging process. [Action] Conducted a thorough analysis and identified a design flaw in the jig. [Result] Implemented a modification to the jig, eliminating component damage and improving production yield by 12%.

- [Challenge] Needed to improve the accuracy of a jig for a highvolume production line. [Action] Used statistical process control techniques to identify and reduce variation in jig dimensions. [Result] Achieved a 30% reduction in component rejection rate.

Awards

- Awarded Jig of the Year for designing and implementing an innovative jig that significantly increased production efficiency by 45%.

- Recognized for exceptional attention to detail and precision in the design and fabrication of critical jigs used in a major automotive manufacturing plant.

- Received a commendation for the development and implementation of a universal jig system, which reduced jig setup time by 65% across multiple assembly lines.

- Recognized for the successful design and fabrication of a specialized jig that enabled the company to manufacture a new product that generated $1 million in revenue.

Certificates

- Certified Jig Maker (CJM)

- Certified Tool and Die Maker (CTDM)

- Coordinate Measuring Machine (CMM) Operator Certification

- Geometric Dimensioning and Tolerancing (GD&T) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Jig Maker

- Highlight your experience and skills in jig design and assembly, CAD/CAM proficiency, and CMM operation.

- Showcase your ability to work independently and as part of a team.

- Emphasize your knowledge of industry standards and safety protocols.

- Provide specific examples of projects or accomplishments that demonstrate your expertise.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Jig Maker Resume

- Design and develop jigs and fixtures for various manufacturing processes, ensuring precision and accuracy.

- Utilize CAD/CAM software to create detailed designs and generate toolpaths for CNC machines.

- Assemble and test jigs and fixtures, ensuring proper functionality and compliance with specifications.

- Conduct quality inspections using Coordinate Measuring Machines (CMM) to ensure the accuracy of manufactured parts.

- Troubleshoot and resolve issues related to jig and fixture performance, optimizing production efficiency.

- Maintain a clean and organized work area, adhering to safety protocols and industry standards.

Frequently Asked Questions (FAQ’s) For Jig Maker

What is the role of a Jig Maker?

A Jig Maker is responsible for designing, assembling, and maintaining jigs and fixtures used in the manufacturing process. Jigs and fixtures are precision-engineered devices that hold, guide, and locate workpieces during manufacturing operations, ensuring accuracy and repeatability.

What are the key skills required for a Jig Maker?

Key skills for a Jig Maker include precision measurement, jig design and assembly, CAD/CAM proficiency, fixture design, Coordinate Measuring Machine (CMM) operation, and Electrical Discharge Machining (EDM).

What is the career outlook for a Jig Maker?

The career outlook for Jig Makers is expected to be good, as the demand for skilled machinists and toolmakers is expected to grow in the coming years.

What are the educational requirements for a Jig Maker?

Most Jig Makers have an Associate’s or Bachelor’s Degree in Mechanical Engineering or a related field.

What is the salary range for a Jig Maker?

The salary range for a Jig Maker can vary depending on experience, location, and industry. According to Indeed, the average salary for a Jig Maker in the United States is around $50,000 per year.

What are the advancement opportunities for a Jig Maker?

With experience and additional training, Jig Makers can advance to roles such as Toolmaker, CNC Programmer, or Manufacturing Engineer.