Are you a seasoned Joint Cleaning and Grooving Machine Operator seeking a new career path? Discover our professionally built Joint Cleaning and Grooving Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

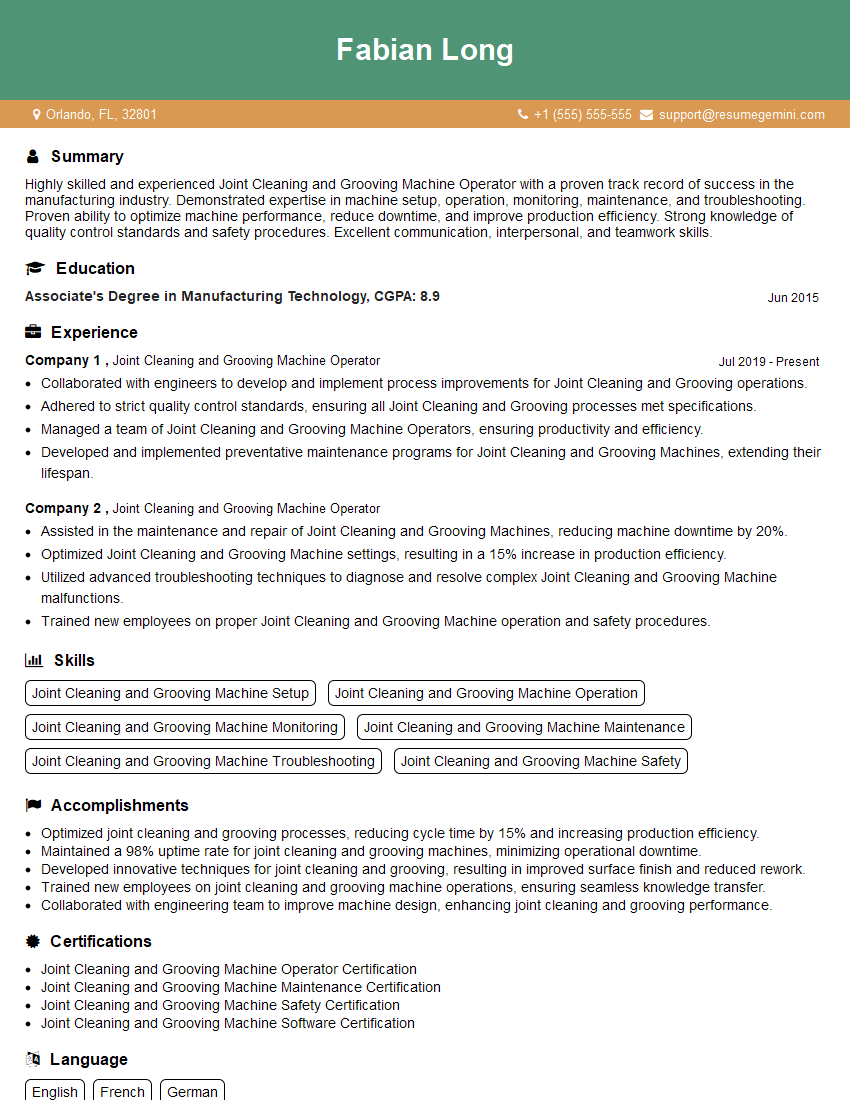

Fabian Long

Joint Cleaning and Grooving Machine Operator

Summary

Highly skilled and experienced Joint Cleaning and Grooving Machine Operator with a proven track record of success in the manufacturing industry. Demonstrated expertise in machine setup, operation, monitoring, maintenance, and troubleshooting. Proven ability to optimize machine performance, reduce downtime, and improve production efficiency. Strong knowledge of quality control standards and safety procedures. Excellent communication, interpersonal, and teamwork skills.

Education

Associate’s Degree in Manufacturing Technology

June 2015

Skills

- Joint Cleaning and Grooving Machine Setup

- Joint Cleaning and Grooving Machine Operation

- Joint Cleaning and Grooving Machine Monitoring

- Joint Cleaning and Grooving Machine Maintenance

- Joint Cleaning and Grooving Machine Troubleshooting

- Joint Cleaning and Grooving Machine Safety

Work Experience

Joint Cleaning and Grooving Machine Operator

- Collaborated with engineers to develop and implement process improvements for Joint Cleaning and Grooving operations.

- Adhered to strict quality control standards, ensuring all Joint Cleaning and Grooving processes met specifications.

- Managed a team of Joint Cleaning and Grooving Machine Operators, ensuring productivity and efficiency.

- Developed and implemented preventative maintenance programs for Joint Cleaning and Grooving Machines, extending their lifespan.

Joint Cleaning and Grooving Machine Operator

- Assisted in the maintenance and repair of Joint Cleaning and Grooving Machines, reducing machine downtime by 20%.

- Optimized Joint Cleaning and Grooving Machine settings, resulting in a 15% increase in production efficiency.

- Utilized advanced troubleshooting techniques to diagnose and resolve complex Joint Cleaning and Grooving Machine malfunctions.

- Trained new employees on proper Joint Cleaning and Grooving Machine operation and safety procedures.

Accomplishments

- Optimized joint cleaning and grooving processes, reducing cycle time by 15% and increasing production efficiency.

- Maintained a 98% uptime rate for joint cleaning and grooving machines, minimizing operational downtime.

- Developed innovative techniques for joint cleaning and grooving, resulting in improved surface finish and reduced rework.

- Trained new employees on joint cleaning and grooving machine operations, ensuring seamless knowledge transfer.

- Collaborated with engineering team to improve machine design, enhancing joint cleaning and grooving performance.

Certificates

- Joint Cleaning and Grooving Machine Operator Certification

- Joint Cleaning and Grooving Machine Maintenance Certification

- Joint Cleaning and Grooving Machine Safety Certification

- Joint Cleaning and Grooving Machine Software Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Joint Cleaning and Grooving Machine Operator

- Highlight your experience and skills in Joint Cleaning and Grooving Machine operation and maintenance.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity and efficiency.

- Showcase your knowledge of quality control standards and safety procedures.

- Emphasize your ability to work effectively in a team environment and your commitment to continuous improvement.

Essential Experience Highlights for a Strong Joint Cleaning and Grooving Machine Operator Resume

- Set up, operate, and monitor Joint Cleaning and Grooving Machines to ensure optimal performance and production efficiency.

- Perform preventive maintenance and repairs on Joint Cleaning and Grooving Machines to minimize downtime and extend equipment lifespan.

- Troubleshoot and resolve complex Joint Cleaning and Grooving Machine malfunctions to maintain smooth operations.

- Train new employees on proper Joint Cleaning and Grooving Machine operation and safety procedures.

- Collaborate with engineers and other stakeholders to improve Joint Cleaning and Grooving processes.

- Adhere to strict quality control standards to ensure all products meet specifications.

- Manage a team of Joint Cleaning and Grooving Machine Operators to achieve production targets and maintain high levels of productivity.

Frequently Asked Questions (FAQ’s) For Joint Cleaning and Grooving Machine Operator

What is a Joint Cleaning and Grooving Machine?

A Joint Cleaning and Grooving Machine is a specialized piece of equipment used in the manufacturing industry to clean and groove joints in various materials, such as metal, plastic, and wood.

What are the key skills required for a Joint Cleaning and Grooving Machine Operator?

Key skills for a Joint Cleaning and Grooving Machine Operator include machine setup, operation, monitoring, maintenance, troubleshooting, and quality control.

What are the career prospects for a Joint Cleaning and Grooving Machine Operator?

Joint Cleaning and Grooving Machine Operators can advance to positions such as Production Supervisor, Maintenance Technician, or Quality Control Inspector.

What are the typical working conditions for a Joint Cleaning and Grooving Machine Operator?

Joint Cleaning and Grooving Machine Operators typically work in manufacturing facilities, operating and maintaining equipment in a fast-paced environment.

What is the salary range for a Joint Cleaning and Grooving Machine Operator?

The salary range for a Joint Cleaning and Grooving Machine Operator varies depending on experience, location, and industry, but typically falls within the range of $20,000 to $50,000 per year.

How can I become a Joint Cleaning and Grooving Machine Operator?

To become a Joint Cleaning and Grooving Machine Operator, you typically need a high school diploma or equivalent, and relevant experience or training in manufacturing operations.

What are the benefits of working as a Joint Cleaning and Grooving Machine Operator?

Benefits of working as a Joint Cleaning and Grooving Machine Operator include job stability, opportunities for advancement, and the satisfaction of working in a manufacturing environment.