Are you a seasoned Journeyman Molder seeking a new career path? Discover our professionally built Journeyman Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

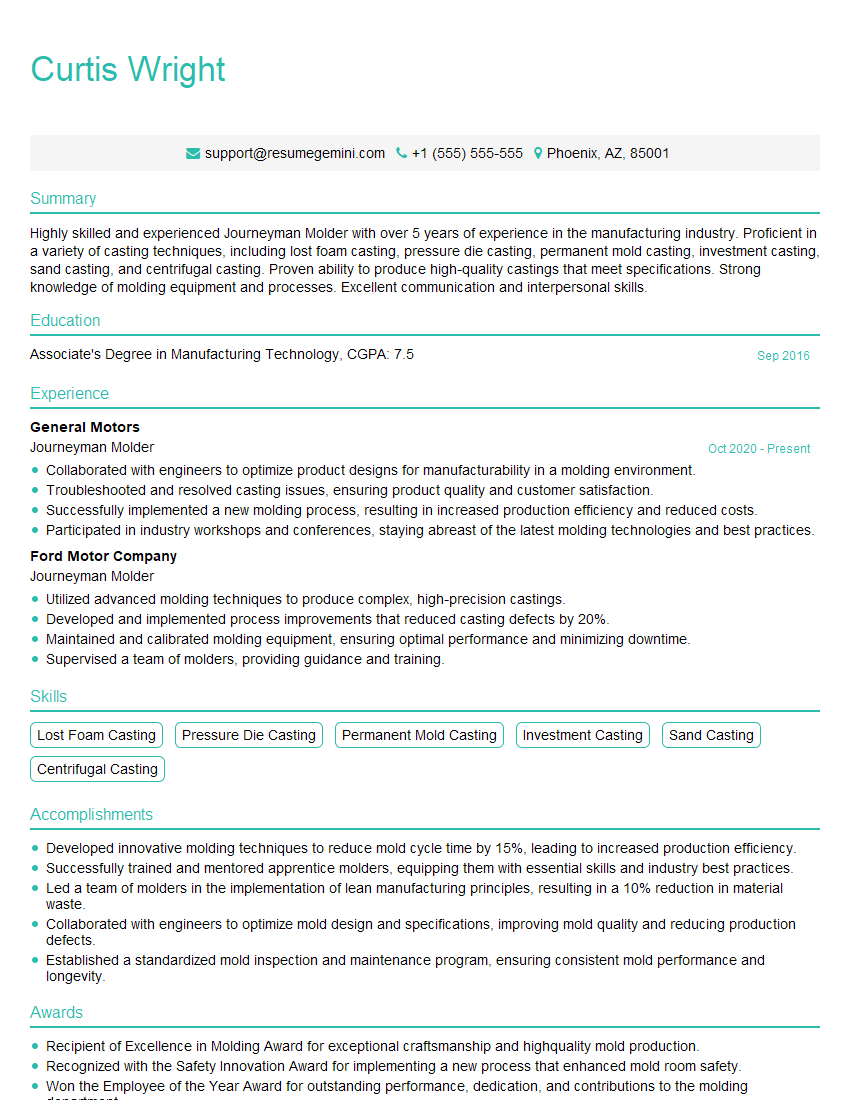

Curtis Wright

Journeyman Molder

Summary

Highly skilled and experienced Journeyman Molder with over 5 years of experience in the manufacturing industry. Proficient in a variety of casting techniques, including lost foam casting, pressure die casting, permanent mold casting, investment casting, sand casting, and centrifugal casting. Proven ability to produce high-quality castings that meet specifications. Strong knowledge of molding equipment and processes. Excellent communication and interpersonal skills.

Education

Associate’s Degree in Manufacturing Technology

September 2016

Skills

- Lost Foam Casting

- Pressure Die Casting

- Permanent Mold Casting

- Investment Casting

- Sand Casting

- Centrifugal Casting

Work Experience

Journeyman Molder

- Collaborated with engineers to optimize product designs for manufacturability in a molding environment.

- Troubleshooted and resolved casting issues, ensuring product quality and customer satisfaction.

- Successfully implemented a new molding process, resulting in increased production efficiency and reduced costs.

- Participated in industry workshops and conferences, staying abreast of the latest molding technologies and best practices.

Journeyman Molder

- Utilized advanced molding techniques to produce complex, high-precision castings.

- Developed and implemented process improvements that reduced casting defects by 20%.

- Maintained and calibrated molding equipment, ensuring optimal performance and minimizing downtime.

- Supervised a team of molders, providing guidance and training.

Accomplishments

- Developed innovative molding techniques to reduce mold cycle time by 15%, leading to increased production efficiency.

- Successfully trained and mentored apprentice molders, equipping them with essential skills and industry best practices.

- Led a team of molders in the implementation of lean manufacturing principles, resulting in a 10% reduction in material waste.

- Collaborated with engineers to optimize mold design and specifications, improving mold quality and reducing production defects.

- Established a standardized mold inspection and maintenance program, ensuring consistent mold performance and longevity.

Awards

- Recipient of Excellence in Molding Award for exceptional craftsmanship and highquality mold production.

- Recognized with the Safety Innovation Award for implementing a new process that enhanced mold room safety.

- Won the Employee of the Year Award for outstanding performance, dedication, and contributions to the molding department.

- Recognized for exceptional performance in mold making and casting processes through the Mold Maker of the Year award.

Certificates

- Journeyman Molder Certification

- Certified Manufacturing Technologist (CMfgT)

- OSHA Safety Certification

- AWS Certified Solutions Architect

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Journeyman Molder

- Highlight your experience and skills in the most relevant areas.

- Use keywords and industry-specific terminology to make your resume stand out.

- Tailor your resume to each specific job you apply for.

- Get your resume reviewed by a qualified professional.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Journeyman Molder Resume

- Set up and operate molding machines

- Create and maintain molds

- Operate casting equipment

- Inspect and test castings

- Troubleshoot and resolve production problems

- Maintain a clean and safe work area

Frequently Asked Questions (FAQ’s) For Journeyman Molder

What is a Journeyman Molder?

A Journeyman Molder is a skilled worker who creates molds for metal castings. They use a variety of techniques to create molds, including lost foam casting, pressure die casting, permanent mold casting, investment casting, sand casting, and centrifugal casting.

What are the job duties of a Journeyman Molder?

The job duties of a Journeyman Molder include setting up and operating molding machines, creating and maintaining molds, operating casting equipment, inspecting and testing castings, troubleshooting and resolving production problems, and maintaining a clean and safe work area.

What are the qualifications for a Journeyman Molder?

The qualifications for a Journeyman Molder typically include an associate’s degree in manufacturing technology and several years of experience in the manufacturing industry. They should also have a strong knowledge of molding equipment and processes.

What is the work environment for a Journeyman Molder?

Journeyman Molders typically work in a manufacturing environment. They may work in a variety of settings, including foundries, machine shops, and other manufacturing facilities. They may also work outdoors in some cases.

What is the salary for a Journeyman Molder?

The salary for a Journeyman Molder can vary depending on their experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Molders and Coremakers was $49,090 in May 2021.

What are the career prospects for a Journeyman Molder?

The career prospects for a Journeyman Molder are good. The demand for skilled workers in the manufacturing industry is expected to grow in the coming years. Journeyman Molders can advance in their careers by taking on more responsibility, becoming supervisors, or starting their own businesses.

What are some tips for becoming a successful Journeyman Molder?

To become a successful Journeyman Molder, it is important to have a strong foundation in manufacturing technology and a passion for the work. It is also important to be able to work independently and as part of a team. Journeyman Molders should also be able to troubleshoot problems and find solutions quickly.

What are some common challenges faced by Journeyman Molders?

Some common challenges faced by Journeyman Molders include working in a fast-paced environment, meeting production deadlines, and working with hazardous materials. They may also need to work overtime or on weekends to meet production demands.