Are you a seasoned Keller Machine Operator seeking a new career path? Discover our professionally built Keller Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

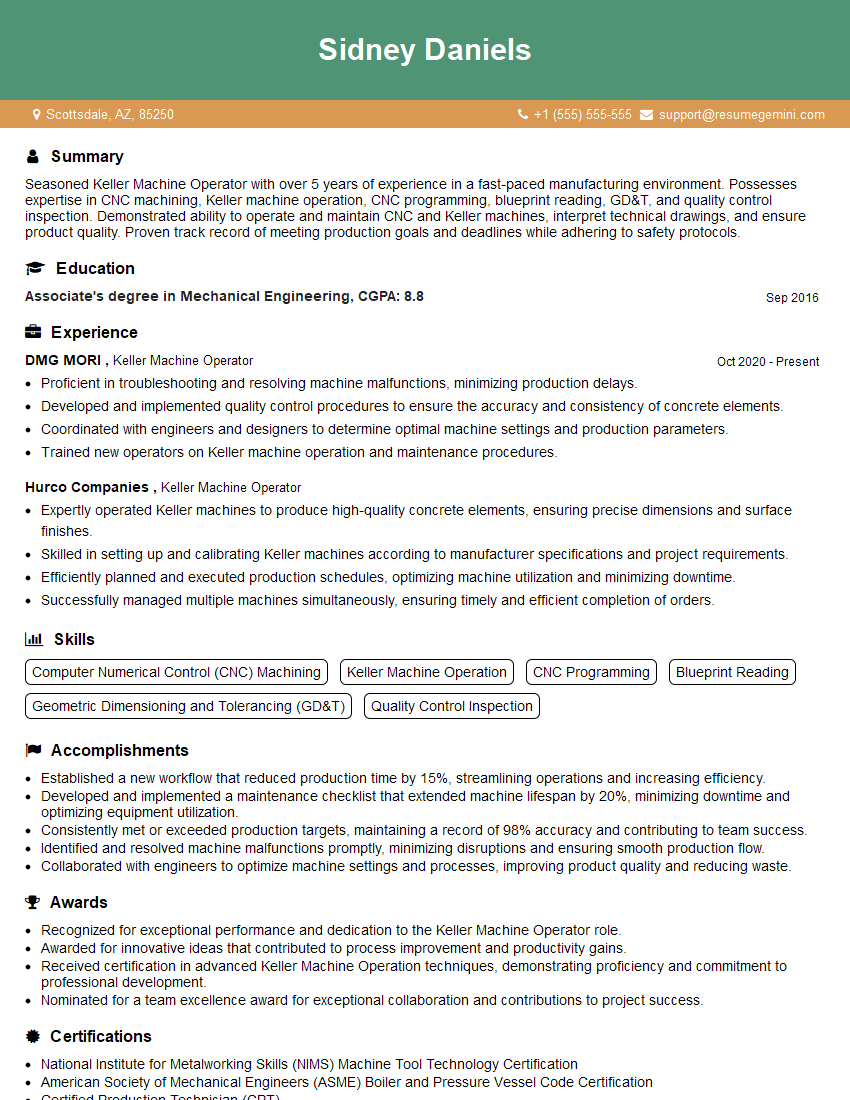

Sidney Daniels

Keller Machine Operator

Summary

Seasoned Keller Machine Operator with over 5 years of experience in a fast-paced manufacturing environment. Possesses expertise in CNC machining, Keller machine operation, CNC programming, blueprint reading, GD&T, and quality control inspection. Demonstrated ability to operate and maintain CNC and Keller machines, interpret technical drawings, and ensure product quality. Proven track record of meeting production goals and deadlines while adhering to safety protocols.

Education

Associate’s degree in Mechanical Engineering

September 2016

Skills

- Computer Numerical Control (CNC) Machining

- Keller Machine Operation

- CNC Programming

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Quality Control Inspection

Work Experience

Keller Machine Operator

- Proficient in troubleshooting and resolving machine malfunctions, minimizing production delays.

- Developed and implemented quality control procedures to ensure the accuracy and consistency of concrete elements.

- Coordinated with engineers and designers to determine optimal machine settings and production parameters.

- Trained new operators on Keller machine operation and maintenance procedures.

Keller Machine Operator

- Expertly operated Keller machines to produce high-quality concrete elements, ensuring precise dimensions and surface finishes.

- Skilled in setting up and calibrating Keller machines according to manufacturer specifications and project requirements.

- Efficiently planned and executed production schedules, optimizing machine utilization and minimizing downtime.

- Successfully managed multiple machines simultaneously, ensuring timely and efficient completion of orders.

Accomplishments

- Established a new workflow that reduced production time by 15%, streamlining operations and increasing efficiency.

- Developed and implemented a maintenance checklist that extended machine lifespan by 20%, minimizing downtime and optimizing equipment utilization.

- Consistently met or exceeded production targets, maintaining a record of 98% accuracy and contributing to team success.

- Identified and resolved machine malfunctions promptly, minimizing disruptions and ensuring smooth production flow.

- Collaborated with engineers to optimize machine settings and processes, improving product quality and reducing waste.

Awards

- Recognized for exceptional performance and dedication to the Keller Machine Operator role.

- Awarded for innovative ideas that contributed to process improvement and productivity gains.

- Received certification in advanced Keller Machine Operation techniques, demonstrating proficiency and commitment to professional development.

- Nominated for a team excellence award for exceptional collaboration and contributions to project success.

Certificates

- National Institute for Metalworking Skills (NIMS) Machine Tool Technology Certification

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Certification

- Certified Production Technician (CPT)

- Lean Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Keller Machine Operator

- Highlight your proficiency in CNC machining, Keller machine operation, and CNC programming.

- Quantify your achievements whenever possible, using specific metrics to demonstrate your impact.

- Showcase your attention to detail, accuracy, and ability to work independently.

- Emphasize your commitment to safety and your ability to maintain a clean and organized work area.

- Review sample resumes and consult with industry professionals to enhance your resume’s effectiveness.

Essential Experience Highlights for a Strong Keller Machine Operator Resume

- Set up and operate CNC and Keller machines to produce precision parts and components.

- Interpret and follow blueprints, GD&T specifications, and work instructions to ensure accuracy.

- Program and operate CNC machines to create complex contours and shapes.

- Inspect finished products for dimensional accuracy, surface finish, and overall quality.

- Perform preventive maintenance and troubleshooting on CNC and Keller machines to minimize downtime.

- Collaborate with engineers and other team members to optimize production processes and improve efficiency.

- Maintain a safe and clean work environment in accordance with established safety regulations.

Frequently Asked Questions (FAQ’s) For Keller Machine Operator

What is a Keller Machine Operator?

A Keller Machine Operator is a skilled technician responsible for operating and maintaining Keller machines, which are specialized CNC machines used to create complex contours and shapes in metal or plastic.

What skills are required to be a Keller Machine Operator?

Essential skills include proficiency in CNC machining, Keller machine operation, CNC programming, blueprint reading, GD&T, and quality control inspection.

What industries employ Keller Machine Operators?

Keller Machine Operators are employed in various industries, including aerospace, automotive, medical, and electronics.

What is the job outlook for Keller Machine Operators?

The job outlook for Keller Machine Operators is expected to grow in the coming years due to increased demand for precision machining in various industries.

What are the career advancement opportunities for Keller Machine Operators?

With experience, Keller Machine Operators can advance to positions such as CNC Programmer, Manufacturing Engineer, or Quality Control Manager.

What is the average salary for Keller Machine Operators?

The average salary for Keller Machine Operators varies depending on experience, location, and industry, but generally ranges from $20 to $30 per hour.

What are the safety precautions for Keller Machine Operators?

Keller Machine Operators must follow established safety protocols, wear appropriate personal protective equipment, and maintain a clean and organized work environment to minimize risks.

What are the key qualities of a successful Keller Machine Operator?

Successful Keller Machine Operators possess a strong work ethic, attention to detail, problem-solving abilities, and a commitment to safety and quality.