Are you a seasoned Kiln Burner Helper seeking a new career path? Discover our professionally built Kiln Burner Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

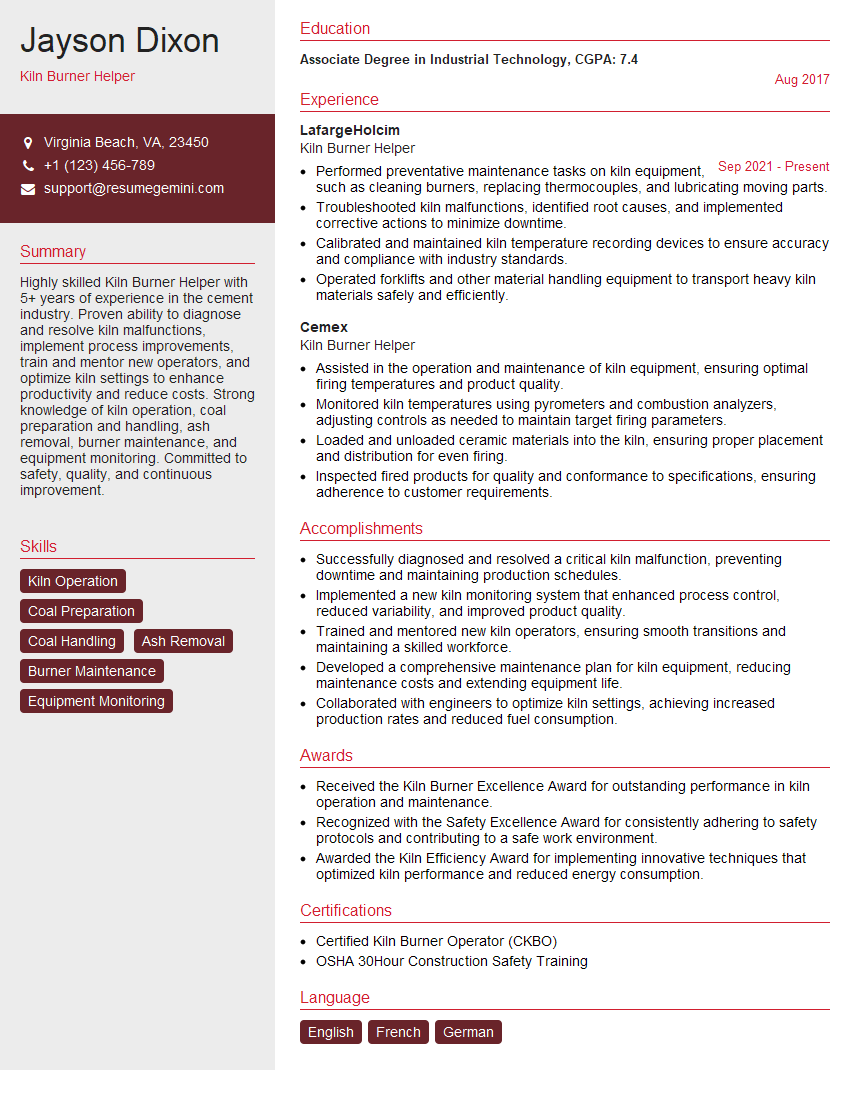

Jayson Dixon

Kiln Burner Helper

Summary

Highly skilled Kiln Burner Helper with 5+ years of experience in the cement industry. Proven ability to diagnose and resolve kiln malfunctions, implement process improvements, train and mentor new operators, and optimize kiln settings to enhance productivity and reduce costs. Strong knowledge of kiln operation, coal preparation and handling, ash removal, burner maintenance, and equipment monitoring. Committed to safety, quality, and continuous improvement.

Education

Associate Degree in Industrial Technology

August 2017

Skills

- Kiln Operation

- Coal Preparation

- Coal Handling

- Ash Removal

- Burner Maintenance

- Equipment Monitoring

Work Experience

Kiln Burner Helper

- Performed preventative maintenance tasks on kiln equipment, such as cleaning burners, replacing thermocouples, and lubricating moving parts.

- Troubleshooted kiln malfunctions, identified root causes, and implemented corrective actions to minimize downtime.

- Calibrated and maintained kiln temperature recording devices to ensure accuracy and compliance with industry standards.

- Operated forklifts and other material handling equipment to transport heavy kiln materials safely and efficiently.

Kiln Burner Helper

- Assisted in the operation and maintenance of kiln equipment, ensuring optimal firing temperatures and product quality.

- Monitored kiln temperatures using pyrometers and combustion analyzers, adjusting controls as needed to maintain target firing parameters.

- Loaded and unloaded ceramic materials into the kiln, ensuring proper placement and distribution for even firing.

- Inspected fired products for quality and conformance to specifications, ensuring adherence to customer requirements.

Accomplishments

- Successfully diagnosed and resolved a critical kiln malfunction, preventing downtime and maintaining production schedules.

- Implemented a new kiln monitoring system that enhanced process control, reduced variability, and improved product quality.

- Trained and mentored new kiln operators, ensuring smooth transitions and maintaining a skilled workforce.

- Developed a comprehensive maintenance plan for kiln equipment, reducing maintenance costs and extending equipment life.

- Collaborated with engineers to optimize kiln settings, achieving increased production rates and reduced fuel consumption.

Awards

- Received the Kiln Burner Excellence Award for outstanding performance in kiln operation and maintenance.

- Recognized with the Safety Excellence Award for consistently adhering to safety protocols and contributing to a safe work environment.

- Awarded the Kiln Efficiency Award for implementing innovative techniques that optimized kiln performance and reduced energy consumption.

Certificates

- Certified Kiln Burner Operator (CKBO)

- OSHA 30Hour Construction Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Kiln Burner Helper

- Highlight your technical skills and experience in kiln operation and maintenance

- Quantify your accomplishments with specific metrics to demonstrate your impact

- Emphasize your commitment to safety and quality

- Showcase your ability to work independently and as part of a team

Essential Experience Highlights for a Strong Kiln Burner Helper Resume

- Operate and monitor kilns to ensure efficient and safe operation

- Prepare and handle coal to meet kiln requirements

- Remove ash from kilns to maintain optimal performance

- Maintain and repair burners to ensure proper combustion

- Monitor equipment and systems to identify and resolve potential issues

- Train and mentor new kiln operators to develop their skills

- Participate in continuous improvement initiatives to enhance kiln performance

Frequently Asked Questions (FAQ’s) For Kiln Burner Helper

What are the key skills required to be a successful Kiln Burner Helper?

Key skills include kiln operation, coal preparation and handling, ash removal, burner maintenance, equipment monitoring, and troubleshooting.

What are the career prospects for Kiln Burner Helpers?

With experience and additional training, Kiln Burner Helpers can advance to positions such as Kiln Operator, Supervisor, or Manager.

What is the work environment like for Kiln Burner Helpers?

Kiln Burner Helpers typically work in industrial settings, such as cement plants or power plants. The work can be physically demanding and may involve exposure to heat, dust, and chemicals.

What are the safety precautions that Kiln Burner Helpers must follow?

Kiln Burner Helpers must adhere to strict safety protocols to minimize risks associated with working with high-temperature equipment and hazardous materials.

What is the earning potential for Kiln Burner Helpers?

The earning potential for Kiln Burner Helpers varies depending on factors such as experience, location, and company. However, they can typically earn a competitive salary and benefits package.

What are the educational requirements to become a Kiln Burner Helper?

While formal education is not always required, many employers prefer candidates with an associate degree in industrial technology or a related field.