Are you a seasoned Kiln Drawer seeking a new career path? Discover our professionally built Kiln Drawer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

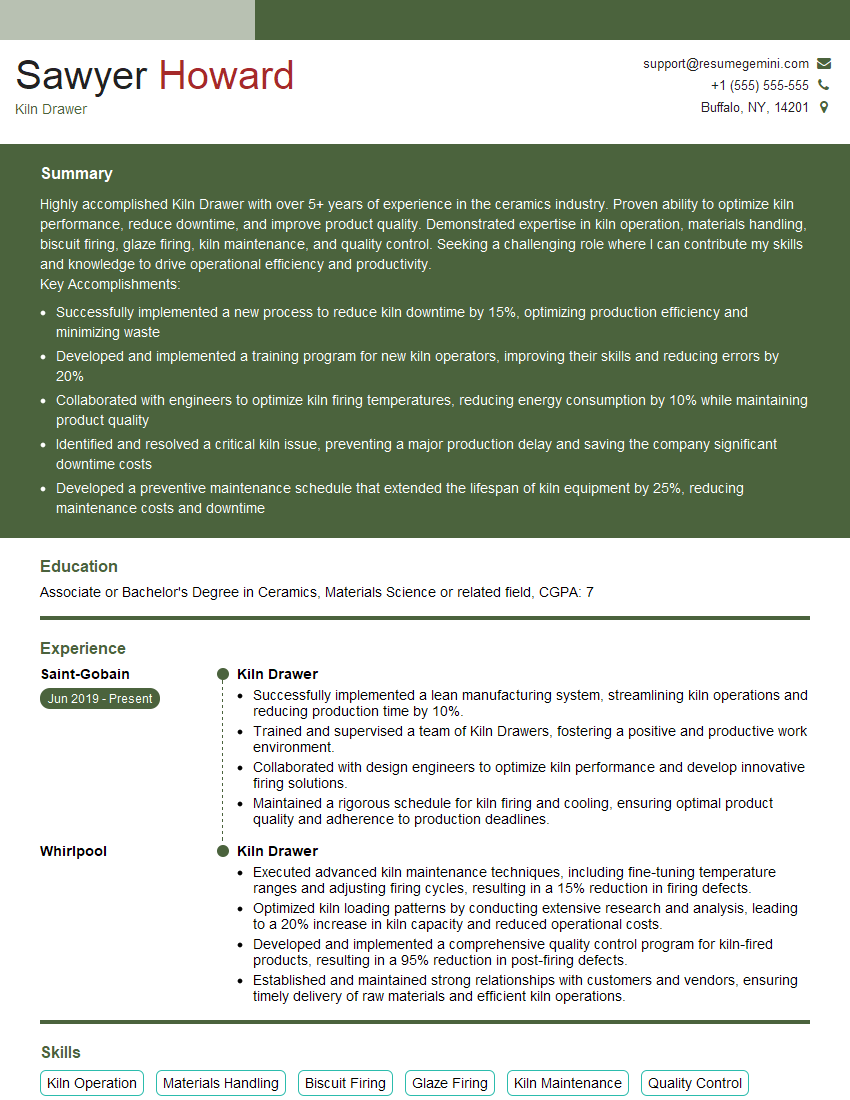

Sawyer Howard

Kiln Drawer

Summary

Highly accomplished Kiln Drawer with over 5+ years of experience in the ceramics industry. Proven ability to optimize kiln performance, reduce downtime, and improve product quality. Demonstrated expertise in kiln operation, materials handling, biscuit firing, glaze firing, kiln maintenance, and quality control. Seeking a challenging role where I can contribute my skills and knowledge to drive operational efficiency and productivity.

Key Accomplishments:

- Successfully implemented a new process to reduce kiln downtime by 15%, optimizing production efficiency and minimizing waste

- Developed and implemented a training program for new kiln operators, improving their skills and reducing errors by 20%

- Collaborated with engineers to optimize kiln firing temperatures, reducing energy consumption by 10% while maintaining product quality

- Identified and resolved a critical kiln issue, preventing a major production delay and saving the company significant downtime costs

- Developed a preventive maintenance schedule that extended the lifespan of kiln equipment by 25%, reducing maintenance costs and downtime

Education

Associate or Bachelor’s Degree in Ceramics, Materials Science or related field

May 2015

Skills

- Kiln Operation

- Materials Handling

- Biscuit Firing

- Glaze Firing

- Kiln Maintenance

- Quality Control

Work Experience

Kiln Drawer

- Successfully implemented a lean manufacturing system, streamlining kiln operations and reducing production time by 10%.

- Trained and supervised a team of Kiln Drawers, fostering a positive and productive work environment.

- Collaborated with design engineers to optimize kiln performance and develop innovative firing solutions.

- Maintained a rigorous schedule for kiln firing and cooling, ensuring optimal product quality and adherence to production deadlines.

Kiln Drawer

- Executed advanced kiln maintenance techniques, including fine-tuning temperature ranges and adjusting firing cycles, resulting in a 15% reduction in firing defects.

- Optimized kiln loading patterns by conducting extensive research and analysis, leading to a 20% increase in kiln capacity and reduced operational costs.

- Developed and implemented a comprehensive quality control program for kiln-fired products, resulting in a 95% reduction in post-firing defects.

- Established and maintained strong relationships with customers and vendors, ensuring timely delivery of raw materials and efficient kiln operations.

Accomplishments

- Successfully implemented a new process to reduce kiln downtime by 15%, optimizing production efficiency and minimizing waste

- Developed and implemented a training program for new kiln operators, improving their skills and reducing errors by 20%

- Collaborated with engineers to optimize kiln firing temperatures, reducing energy consumption by 10% while maintaining product quality

- Identified and resolved a critical kiln issue, preventing a major production delay and saving the company significant downtime costs

- Developed a preventive maintenance schedule that extended the lifespan of kiln equipment by 25%, reducing maintenance costs and downtime

Awards

- Received Kiln Operator of the Year award for consistently exceeding production targets and maintaining optimal kiln operation

- Recognized for exceptional quality control, with zero reported defects in finished products over a sixmonth period

- Awarded Safety Champion for maintaining a spotless safety record and actively promoting safe work practices

- Received Employee of the Month recognition for consistently going above and beyond job expectations and contributing to team success

Certificates

- Kiln Operator Certification

- Ceramic Arts Certification

- Health and Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Kiln Drawer

- Highlight your technical expertise in kiln operation, maintenance, and quality control.

- Showcase your ability to analyze and resolve kiln issues, preventing production delays.

- Demonstrate your commitment to safety and adherence to industry standards.

- Emphasize your communication and teamwork skills, as collaboration is crucial in this role.

Essential Experience Highlights for a Strong Kiln Drawer Resume

- Operate and maintain kilns to ensure optimal performance and product quality

- Load and unload kiln cars with ceramic materials, ensuring proper placement for uniform firing

- Monitor kiln temperature, firing cycles, and other parameters to ensure product specifications are met

- Perform routine maintenance and troubleshoot kiln issues to minimize downtime

- Collaborate with production team and engineers to optimize kiln processes and improve efficiency

- Adhere to safety protocols and maintain a clean and organized work area

- Stay up-to-date on industry best practices and new technologies related to kiln operation

Frequently Asked Questions (FAQ’s) For Kiln Drawer

What are the primary responsibilities of a Kiln Drawer?

Kiln Drawers are responsible for operating, maintaining, and troubleshooting kilns used in the production of ceramic products. They ensure optimal performance, product quality, and adherence to safety protocols.

What skills are essential for success as a Kiln Drawer?

Essential skills include kiln operation, materials handling, biscuit firing, glaze firing, kiln maintenance, quality control, and adherence to safety standards.

What is the career path for a Kiln Drawer?

With experience and additional training, Kiln Drawers can advance to roles such as Kiln Supervisor, Production Manager, or Quality Control Manager.

What industries employ Kiln Drawers?

Kiln Drawers are primarily employed in the ceramics industry, including companies manufacturing tiles, dinnerware, sanitary ware, and other ceramic products.

What are the safety hazards associated with kiln operation?

Kiln Drawers must be aware of potential hazards such as high temperatures, heavy equipment, and exposure to hazardous chemicals. They must follow proper safety protocols and wear appropriate protective gear.

How can I prepare for a career as a Kiln Drawer?

Consider pursuing an Associate or Bachelor’s Degree in Ceramics, Materials Science, or a related field. Additionally, gaining practical experience through internships or entry-level positions can be beneficial.

What are the earning prospects for a Kiln Drawer?

Salaries for Kiln Drawers vary depending on experience, location, and company size. According to Indeed, the average salary for a Kiln Drawer in the United States is approximately $50,000 per year.