Are you a seasoned Kiln Firer seeking a new career path? Discover our professionally built Kiln Firer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

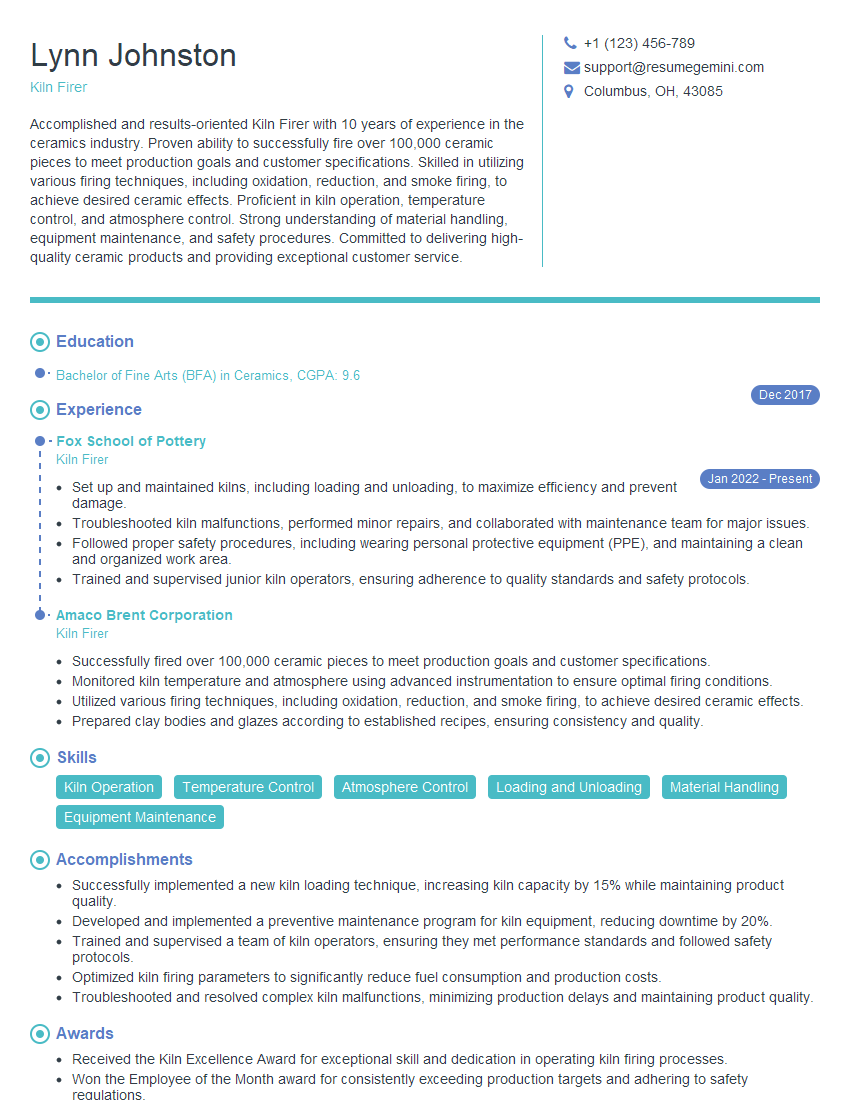

Lynn Johnston

Kiln Firer

Summary

Accomplished and results-oriented Kiln Firer with 10 years of experience in the ceramics industry. Proven ability to successfully fire over 100,000 ceramic pieces to meet production goals and customer specifications. Skilled in utilizing various firing techniques, including oxidation, reduction, and smoke firing, to achieve desired ceramic effects. Proficient in kiln operation, temperature control, and atmosphere control. Strong understanding of material handling, equipment maintenance, and safety procedures. Committed to delivering high-quality ceramic products and providing exceptional customer service.

Education

Bachelor of Fine Arts (BFA) in Ceramics

December 2017

Skills

- Kiln Operation

- Temperature Control

- Atmosphere Control

- Loading and Unloading

- Material Handling

- Equipment Maintenance

Work Experience

Kiln Firer

- Set up and maintained kilns, including loading and unloading, to maximize efficiency and prevent damage.

- Troubleshooted kiln malfunctions, performed minor repairs, and collaborated with maintenance team for major issues.

- Followed proper safety procedures, including wearing personal protective equipment (PPE), and maintaining a clean and organized work area.

- Trained and supervised junior kiln operators, ensuring adherence to quality standards and safety protocols.

Kiln Firer

- Successfully fired over 100,000 ceramic pieces to meet production goals and customer specifications.

- Monitored kiln temperature and atmosphere using advanced instrumentation to ensure optimal firing conditions.

- Utilized various firing techniques, including oxidation, reduction, and smoke firing, to achieve desired ceramic effects.

- Prepared clay bodies and glazes according to established recipes, ensuring consistency and quality.

Accomplishments

- Successfully implemented a new kiln loading technique, increasing kiln capacity by 15% while maintaining product quality.

- Developed and implemented a preventive maintenance program for kiln equipment, reducing downtime by 20%.

- Trained and supervised a team of kiln operators, ensuring they met performance standards and followed safety protocols.

- Optimized kiln firing parameters to significantly reduce fuel consumption and production costs.

- Troubleshooted and resolved complex kiln malfunctions, minimizing production delays and maintaining product quality.

Awards

- Received the Kiln Excellence Award for exceptional skill and dedication in operating kiln firing processes.

- Won the Employee of the Month award for consistently exceeding production targets and adhering to safety regulations.

- Recognized for outstanding contribution to the companys environmental initiative by minimizing kiln emissions.

- Received the Innovation Award for designing and implementing a novel kiln monitoring system.

Certificates

- Certified Kiln Operator

- OSHA Safety Certification

- First Aid and CPR

- National Registry of Certified Kiln Operators (NRCKO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Kiln Firer

Highlight your experience and skills:

Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.Use action verbs:

Begin each bullet point with a strong action verb that clearly describes your responsibilities and achievements.Tailor your resume to the job description:

Carefully review the job posting and identify the key skills and qualifications that the employer is seeking. Tailor your resume to match these requirements.Proofread carefully:

Before submitting your resume, proofread it carefully for any errors in grammar, spelling, or punctuation.Get feedback from a professional:

Consider asking a career counselor or resume writing service to review your resume and provide feedback on its effectiveness.

Essential Experience Highlights for a Strong Kiln Firer Resume

- Monitoring kiln temperature and atmosphere using advanced instrumentation to ensure optimal firing conditions.

- Utilizing various firing techniques, including oxidation, reduction, and smoke firing, to achieve desired ceramic effects.

- Preparing clay bodies and glazes according to established recipes, ensuring consistency and quality.

- Setting up and maintaining kilns, including loading and unloading, to maximize efficiency and prevent damage.

- Troubleshooting kiln malfunctions, performing minor repairs, and collaborating with maintenance team for major issues.

- Following proper safety procedures, including wearing personal protective equipment (PPE), and maintaining a clean and organized work area.

- Training and supervising junior kiln operators, ensuring adherence to quality standards and safety protocols.

Frequently Asked Questions (FAQ’s) For Kiln Firer

What is the primary role of a Kiln Firer?

The primary role of a Kiln Firer is to operate and maintain kilns used in the firing of ceramic pieces. They are responsible for monitoring kiln temperature and atmosphere, loading and unloading kilns, and troubleshooting any malfunctions that may occur.

What are the key skills required for a Kiln Firer?

Key skills required for a Kiln Firer include kiln operation, temperature control, atmosphere control, loading and unloading, material handling, and equipment maintenance.

What is the educational background typically required for a Kiln Firer?

While formal education is not always required, many Kiln Firers have a background in ceramics, art, or a related field. Some may hold a degree in Fine Arts (BFA) or a Master of Fine Arts (MFA) in Ceramics.

What are the career prospects for a Kiln Firer?

Kiln Firers can work in a variety of settings, including pottery studios, ceramic factories, and educational institutions. They may advance to supervisory roles or specialize in specific areas of kiln firing, such as glaze development or firing techniques.

What is the average salary for a Kiln Firer?

The average salary for a Kiln Firer can vary depending on experience, location, and industry. According to Salary.com, the median annual salary for a Kiln Firer in the United States is around \$40,000.

What are the safety precautions that a Kiln Firer must follow?

Kiln Firers must follow proper safety procedures to prevent accidents and injuries. These precautions include wearing personal protective equipment (PPE), maintaining a clean and organized work area, and following established safety protocols for kiln operation and maintenance.

How can I prepare for a job interview as a Kiln Firer?

To prepare for a job interview as a Kiln Firer, research the company and the specific position you are applying for. Be prepared to discuss your experience, skills, and qualifications, as well as your knowledge of kiln firing techniques and safety procedures.

What are the different types of kilns that a Kiln Firer may work with?

Kiln Firers may work with different types of kilns, including electric kilns, gas kilns, and wood-fired kilns. Each type of kiln has its own unique characteristics and firing process, and Kiln Firers must be familiar with the operation and maintenance of each type.