Are you a seasoned Kiln Mechanic seeking a new career path? Discover our professionally built Kiln Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

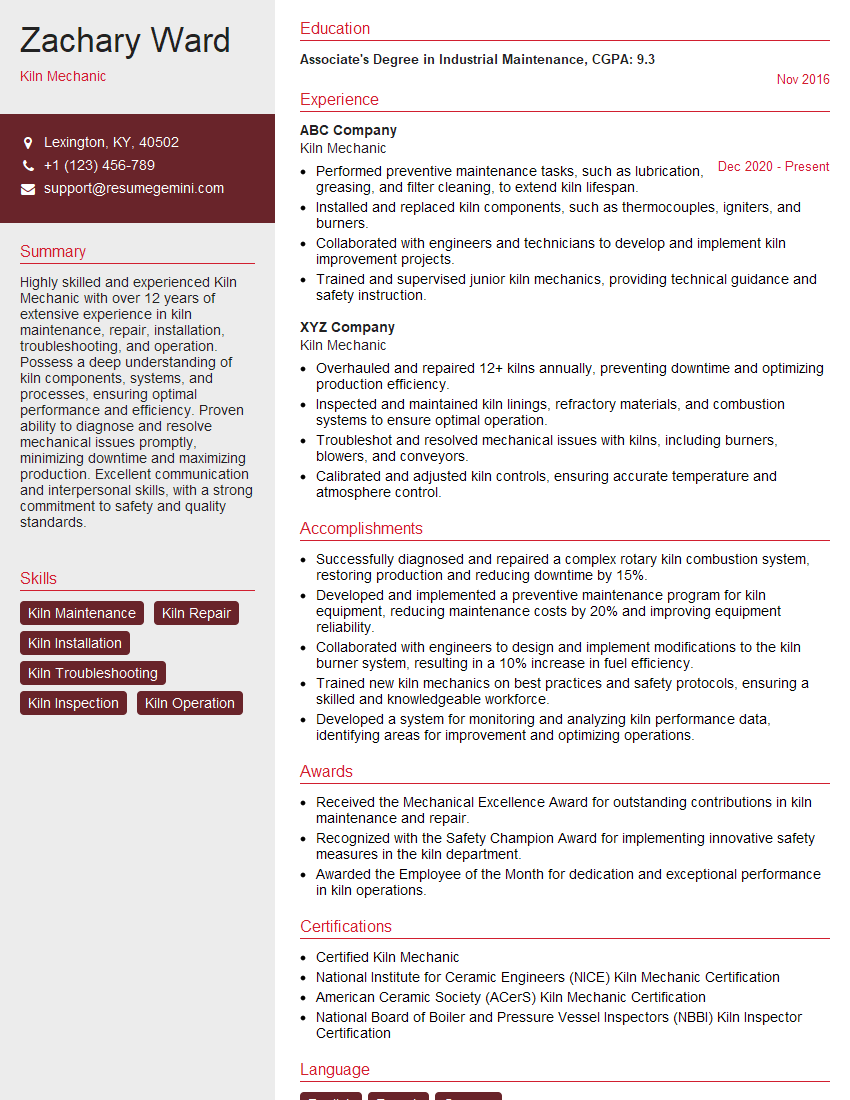

Zachary Ward

Kiln Mechanic

Summary

Highly skilled and experienced Kiln Mechanic with over 12 years of extensive experience in kiln maintenance, repair, installation, troubleshooting, and operation. Possess a deep understanding of kiln components, systems, and processes, ensuring optimal performance and efficiency. Proven ability to diagnose and resolve mechanical issues promptly, minimizing downtime and maximizing production. Excellent communication and interpersonal skills, with a strong commitment to safety and quality standards.

Education

Associate’s Degree in Industrial Maintenance

November 2016

Skills

- Kiln Maintenance

- Kiln Repair

- Kiln Installation

- Kiln Troubleshooting

- Kiln Inspection

- Kiln Operation

Work Experience

Kiln Mechanic

- Performed preventive maintenance tasks, such as lubrication, greasing, and filter cleaning, to extend kiln lifespan.

- Installed and replaced kiln components, such as thermocouples, igniters, and burners.

- Collaborated with engineers and technicians to develop and implement kiln improvement projects.

- Trained and supervised junior kiln mechanics, providing technical guidance and safety instruction.

Kiln Mechanic

- Overhauled and repaired 12+ kilns annually, preventing downtime and optimizing production efficiency.

- Inspected and maintained kiln linings, refractory materials, and combustion systems to ensure optimal operation.

- Troubleshot and resolved mechanical issues with kilns, including burners, blowers, and conveyors.

- Calibrated and adjusted kiln controls, ensuring accurate temperature and atmosphere control.

Accomplishments

- Successfully diagnosed and repaired a complex rotary kiln combustion system, restoring production and reducing downtime by 15%.

- Developed and implemented a preventive maintenance program for kiln equipment, reducing maintenance costs by 20% and improving equipment reliability.

- Collaborated with engineers to design and implement modifications to the kiln burner system, resulting in a 10% increase in fuel efficiency.

- Trained new kiln mechanics on best practices and safety protocols, ensuring a skilled and knowledgeable workforce.

- Developed a system for monitoring and analyzing kiln performance data, identifying areas for improvement and optimizing operations.

Awards

- Received the Mechanical Excellence Award for outstanding contributions in kiln maintenance and repair.

- Recognized with the Safety Champion Award for implementing innovative safety measures in the kiln department.

- Awarded the Employee of the Month for dedication and exceptional performance in kiln operations.

Certificates

- Certified Kiln Mechanic

- National Institute for Ceramic Engineers (NICE) Kiln Mechanic Certification

- American Ceramic Society (ACerS) Kiln Mechanic Certification

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Kiln Inspector Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Kiln Mechanic

Highlight your core competencies:

Showcase your expertise in kiln maintenance, repair, troubleshooting, and process optimization.Quantify your accomplishments:

Use numbers and metrics to demonstrate the impact of your work in terms of downtime reduction, production efficiency gains, and cost savings.Emphasize safety and quality:

Highlight your commitment to safety and quality standards, ensuring compliance with industry regulations and company policies.Showcase your problem-solving abilities:

Provide examples of complex mechanical issues you have successfully diagnosed and resolved, minimizing downtime and maximizing productivity.Demonstrate your teamwork and communication skills:

Highlight your ability to collaborate effectively with engineers, technicians, and other team members, contributing to a positive and productive work environment.

Essential Experience Highlights for a Strong Kiln Mechanic Resume

- Overhaul and repair kilns to prevent downtime and ensure optimal production efficiency.

- Inspect and maintain kiln linings, refractory materials, and combustion systems to guarantee optimal operation.

- Troubleshoot and resolve mechanical issues with kilns, including burners, blowers, and conveyors, to maintain smooth operation.

- Calibrate and adjust kiln controls to ensure accurate temperature and atmosphere control.

- Perform preventive maintenance tasks, such as lubrication, greasing, and filter cleaning, to extend kiln lifespan and minimize breakdowns.

- Install and replace kiln components, such as thermocouples, igniters, and burners, ensuring proper functionality and safety.

- Collaborate with engineers and technicians to develop and implement kiln improvement projects, enhancing performance and efficiency.

Frequently Asked Questions (FAQ’s) For Kiln Mechanic

What are the primary responsibilities of a Kiln Mechanic?

Kiln Mechanics are responsible for maintaining, repairing, installing, troubleshooting, and operating kilns. They ensure that kilns are operating efficiently and safely, minimizing downtime and maximizing production.

What skills and qualifications are required to become a Kiln Mechanic?

Kiln Mechanics typically require an Associate’s Degree in Industrial Maintenance or a related field. They should have a strong understanding of kiln components, systems, and processes, as well as mechanical and electrical troubleshooting skills.

What industries employ Kiln Mechanics?

Kiln Mechanics are employed in various industries, including ceramics, glass, cement, and other manufacturing sectors that utilize kilns for processing materials.

What is the typical work environment for a Kiln Mechanic?

Kiln Mechanics typically work in industrial settings, such as factories or manufacturing plants. They may be exposed to heat, noise, and dust, and may work in confined spaces.

What are the career advancement opportunities for a Kiln Mechanic?

Kiln Mechanics with experience and expertise can advance to supervisory roles, such as Kiln Maintenance Supervisor or Kiln Operations Manager. They may also specialize in specific areas, such as kiln design or automation.

What is the job outlook for Kiln Mechanics?

The job outlook for Kiln Mechanics is expected to be good in the coming years, due to the increasing demand for skilled technicians in the manufacturing sector.