Are you a seasoned Kiln Worker seeking a new career path? Discover our professionally built Kiln Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

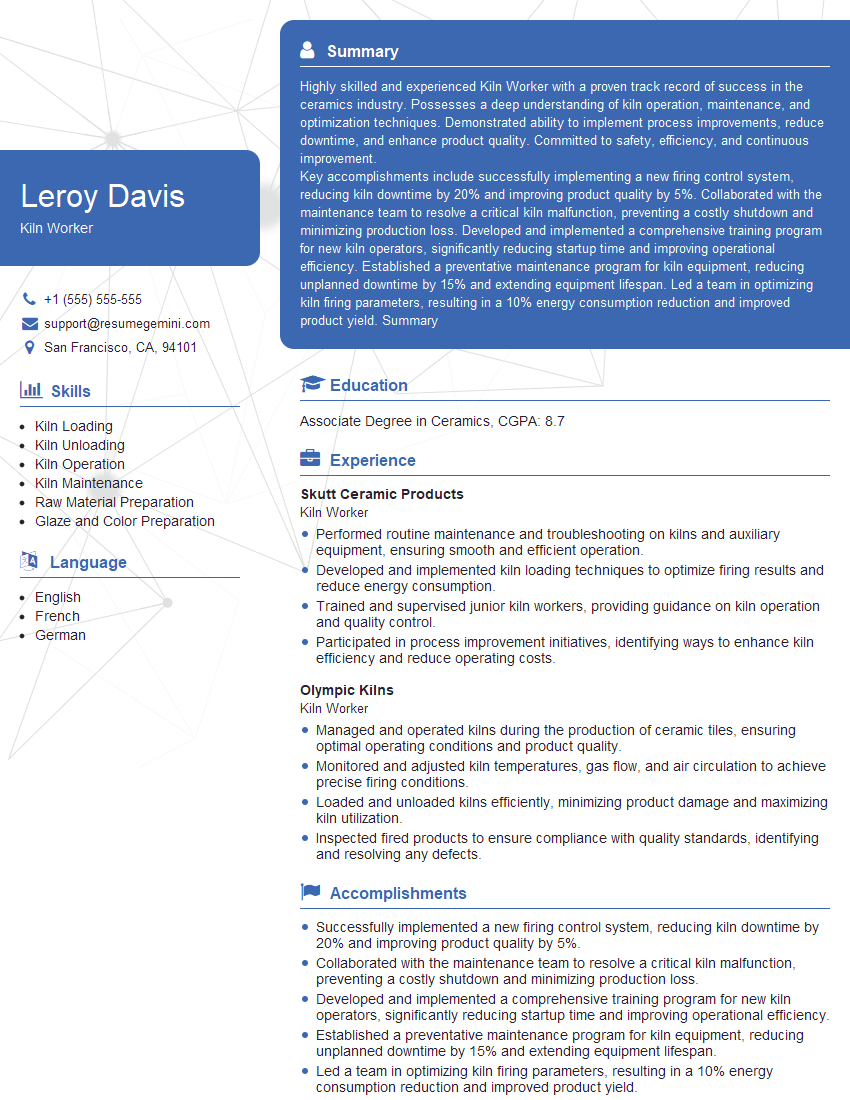

Leroy Davis

Kiln Worker

Summary

Highly skilled and experienced Kiln Worker with a proven track record of success in the ceramics industry. Possesses a deep understanding of kiln operation, maintenance, and optimization techniques. Demonstrated ability to implement process improvements, reduce downtime, and enhance product quality. Committed to safety, efficiency, and continuous improvement.

Key accomplishments include successfully implementing a new firing control system, reducing kiln downtime by 20% and improving product quality by 5%. Collaborated with the maintenance team to resolve a critical kiln malfunction, preventing a costly shutdown and minimizing production loss. Developed and implemented a comprehensive training program for new kiln operators, significantly reducing startup time and improving operational efficiency. Established a preventative maintenance program for kiln equipment, reducing unplanned downtime by 15% and extending equipment lifespan. Led a team in optimizing kiln firing parameters, resulting in a 10% energy consumption reduction and improved product yield. Summary

Education

Associate Degree in Ceramics

August 2019

Skills

- Kiln Loading

- Kiln Unloading

- Kiln Operation

- Kiln Maintenance

- Raw Material Preparation

- Glaze and Color Preparation

Work Experience

Kiln Worker

- Performed routine maintenance and troubleshooting on kilns and auxiliary equipment, ensuring smooth and efficient operation.

- Developed and implemented kiln loading techniques to optimize firing results and reduce energy consumption.

- Trained and supervised junior kiln workers, providing guidance on kiln operation and quality control.

- Participated in process improvement initiatives, identifying ways to enhance kiln efficiency and reduce operating costs.

Kiln Worker

- Managed and operated kilns during the production of ceramic tiles, ensuring optimal operating conditions and product quality.

- Monitored and adjusted kiln temperatures, gas flow, and air circulation to achieve precise firing conditions.

- Loaded and unloaded kilns efficiently, minimizing product damage and maximizing kiln utilization.

- Inspected fired products to ensure compliance with quality standards, identifying and resolving any defects.

Accomplishments

- Successfully implemented a new firing control system, reducing kiln downtime by 20% and improving product quality by 5%.

- Collaborated with the maintenance team to resolve a critical kiln malfunction, preventing a costly shutdown and minimizing production loss.

- Developed and implemented a comprehensive training program for new kiln operators, significantly reducing startup time and improving operational efficiency.

- Established a preventative maintenance program for kiln equipment, reducing unplanned downtime by 15% and extending equipment lifespan.

- Led a team in optimizing kiln firing parameters, resulting in a 10% energy consumption reduction and improved product yield.

Awards

- Received the Plants Monthly Safety Award for maintaining an exceptional safety record throughout the production process.

- Recognized for outstanding performance in managing multiple kiln operations simultaneously, ensuring optimal production throughput.

- Received the Departments Team Player Award for actively mentoring new kiln operators and fostering a positive work environment.

- Recognized for exceptional knowledge of kiln operations and troubleshooting techniques, effectively resolving complex issues and maintaining production quality.

Certificates

- Kiln Operator Certification

- OSHA Safety Certification

- EPA Environmental Compliance Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Kiln Worker

- Highlight your technical skills and experience in kiln operation and maintenance.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Emphasize your ability to work independently and as part of a team.

- Include relevant certifications or training that demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Kiln Worker Resume

- Operate and monitor kilns to ensure optimal firing conditions

- Load and unload kilns efficiently and safely

- Perform routine maintenance and repairs on kilns and related equipment

- Monitor and adjust kiln temperatures, pressure, and atmosphere

- Troubleshoot and resolve kiln malfunctions

- Maintain accurate records of kiln operations and performance

- Collaborate with other team members to ensure smooth production processes

Frequently Asked Questions (FAQ’s) For Kiln Worker

What is the primary role of a Kiln Worker?

The primary role of a Kiln Worker is to operate, maintain, and optimize kilns used in the ceramics industry to produce high-quality ceramic products.

What are the key skills required for a Kiln Worker?

Key skills for a Kiln Worker include kiln operation, kiln maintenance, raw material preparation, glaze and color preparation, and a understanding of ceramic processes.

What is the work environment of a Kiln Worker like?

Kiln Workers typically work in manufacturing facilities or ceramic studios. The work environment may involve exposure to heat, dust, and chemicals, and may require physical exertion.

What are the career prospects for a Kiln Worker?

Kiln Workers may advance to supervisory roles or specialize in kiln design or maintenance. With experience and training, they may also transition to related roles in the ceramics industry.

What are the safety precautions that Kiln Workers must observe?

Kiln Workers must observe safety precautions such as wearing appropriate protective gear, following established operating procedures, and being aware of potential hazards associated with kiln operation.

How can I prepare for a career as a Kiln Worker?

To prepare for a career as a Kiln Worker, you can pursue an associate degree in ceramics, take specialized training programs, or gain experience through apprenticeships or entry-level positions in the ceramics industry.

What are the different types of kilns used in the ceramics industry?

There are various types of kilns used in the ceramics industry, including electric kilns, gas kilns, wood-fired kilns, and raku kilns, each with its own unique characteristics and applications.