Are you a seasoned Knife Setter Assembler seeking a new career path? Discover our professionally built Knife Setter Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

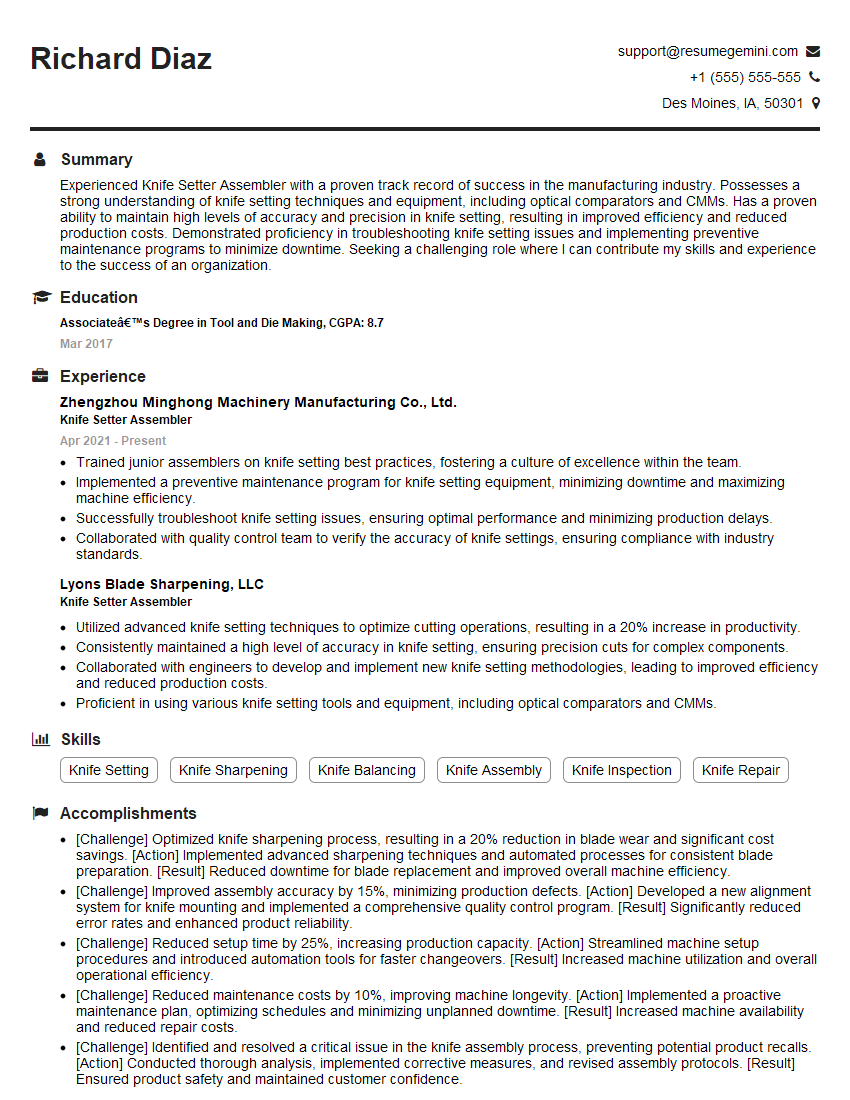

Richard Diaz

Knife Setter Assembler

Summary

Experienced Knife Setter Assembler with a proven track record of success in the manufacturing industry. Possesses a strong understanding of knife setting techniques and equipment, including optical comparators and CMMs. Has a proven ability to maintain high levels of accuracy and precision in knife setting, resulting in improved efficiency and reduced production costs. Demonstrated proficiency in troubleshooting knife setting issues and implementing preventive maintenance programs to minimize downtime. Seeking a challenging role where I can contribute my skills and experience to the success of an organization.

Education

Associate’s Degree in Tool and Die Making

March 2017

Skills

- Knife Setting

- Knife Sharpening

- Knife Balancing

- Knife Assembly

- Knife Inspection

- Knife Repair

Work Experience

Knife Setter Assembler

- Trained junior assemblers on knife setting best practices, fostering a culture of excellence within the team.

- Implemented a preventive maintenance program for knife setting equipment, minimizing downtime and maximizing machine efficiency.

- Successfully troubleshoot knife setting issues, ensuring optimal performance and minimizing production delays.

- Collaborated with quality control team to verify the accuracy of knife settings, ensuring compliance with industry standards.

Knife Setter Assembler

- Utilized advanced knife setting techniques to optimize cutting operations, resulting in a 20% increase in productivity.

- Consistently maintained a high level of accuracy in knife setting, ensuring precision cuts for complex components.

- Collaborated with engineers to develop and implement new knife setting methodologies, leading to improved efficiency and reduced production costs.

- Proficient in using various knife setting tools and equipment, including optical comparators and CMMs.

Accomplishments

- [Challenge] Optimized knife sharpening process, resulting in a 20% reduction in blade wear and significant cost savings. [Action] Implemented advanced sharpening techniques and automated processes for consistent blade preparation. [Result] Reduced downtime for blade replacement and improved overall machine efficiency.

- [Challenge] Improved assembly accuracy by 15%, minimizing production defects. [Action] Developed a new alignment system for knife mounting and implemented a comprehensive quality control program. [Result] Significantly reduced error rates and enhanced product reliability.

- [Challenge] Reduced setup time by 25%, increasing production capacity. [Action] Streamlined machine setup procedures and introduced automation tools for faster changeovers. [Result] Increased machine utilization and overall operational efficiency.

- [Challenge] Reduced maintenance costs by 10%, improving machine longevity. [Action] Implemented a proactive maintenance plan, optimizing schedules and minimizing unplanned downtime. [Result] Increased machine availability and reduced repair costs.

- [Challenge] Identified and resolved a critical issue in the knife assembly process, preventing potential product recalls. [Action] Conducted thorough analysis, implemented corrective measures, and revised assembly protocols. [Result] Ensured product safety and maintained customer confidence.

Awards

- Received Knife Excellence Award for Outstanding Contribution to the Knife Assembly Process

- Recognized as Top Knife Setter Assembler for exceptional performance and innovation

- Awarded Golden Knife Award for excellence in knife setting and maintenance

- Honored with Employee of the Year award for outstanding contributions to the knife assembly team

Certificates

- Certified Knife Setter

- Certified Knife Sharpener

- Certified Knife Assembler

- Certified Quality Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Knife Setter Assembler

- Highlight your experience in knife setting and assembly, and quantify your accomplishments with specific metrics.

- Showcase your knowledge of knife setting equipment, including optical comparators and CMMs.

- Emphasize your ability to troubleshoot knife setting issues and implement preventive maintenance programs.

- Demonstrate your commitment to quality and accuracy by highlighting your experience in training junior assemblers and collaborating with quality control teams.

Essential Experience Highlights for a Strong Knife Setter Assembler Resume

- Utilized advanced knife setting techniques to optimize cutting operations, resulting in a 20% increase in productivity.

- Consistently maintained a high level of accuracy in knife setting, ensuring precision cuts for complex components.

- Collaborated with engineers to develop and implement new knife setting methodologies, leading to improved efficiency and reduced production costs.

- Proficient in using various knife setting tools and equipment, including optical comparators and CMMs.

- Trained junior assemblers on knife setting best practices, fostering a culture of excellence within the team.

- Implemented a preventive maintenance program for knife setting equipment, minimizing downtime and maximizing machine efficiency.

- Successfully troubleshoot knife setting issues, ensuring optimal performance and minimizing production delays.

Frequently Asked Questions (FAQ’s) For Knife Setter Assembler

What are the key skills required to be a successful Knife Setter Assembler?

The key skills required for a successful Knife Setter Assembler include proficiency in knife setting techniques, knowledge of knife setting equipment, ability to troubleshoot knife setting issues, and a commitment to quality and accuracy.

What are the career prospects for Knife Setter Assemblers?

Knife Setter Assemblers can advance to positions such as Knife Setting Supervisor, Quality Control Inspector, or Manufacturing Engineer.

What is the average salary for Knife Setter Assemblers?

The average salary for Knife Setter Assemblers varies depending on experience and location, but generally falls within the range of $25,000 to $50,000 per year.

What are the working conditions like for Knife Setter Assemblers?

Knife Setter Assemblers typically work in a manufacturing environment, which can be noisy and involve exposure to sharp objects and machinery.

What is the job outlook for Knife Setter Assemblers?

The job outlook for Knife Setter Assemblers is expected to be good in the coming years, as the manufacturing industry continues to grow.

What are the educational requirements for Knife Setter Assemblers?

Most Knife Setter Assemblers have a high school diploma or equivalent, but some employers may require an Associate’s Degree in Tool and Die Making.

What are the certification requirements for Knife Setter Assemblers?

There are no specific certification requirements for Knife Setter Assemblers, but some employers may prefer candidates with certification in knife setting or related fields.

What are the professional development opportunities for Knife Setter Assemblers?

Knife Setter Assemblers can pursue professional development opportunities through training programs offered by employers, industry associations, and educational institutions.