Are you a seasoned Labeling Machine Operator seeking a new career path? Discover our professionally built Labeling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

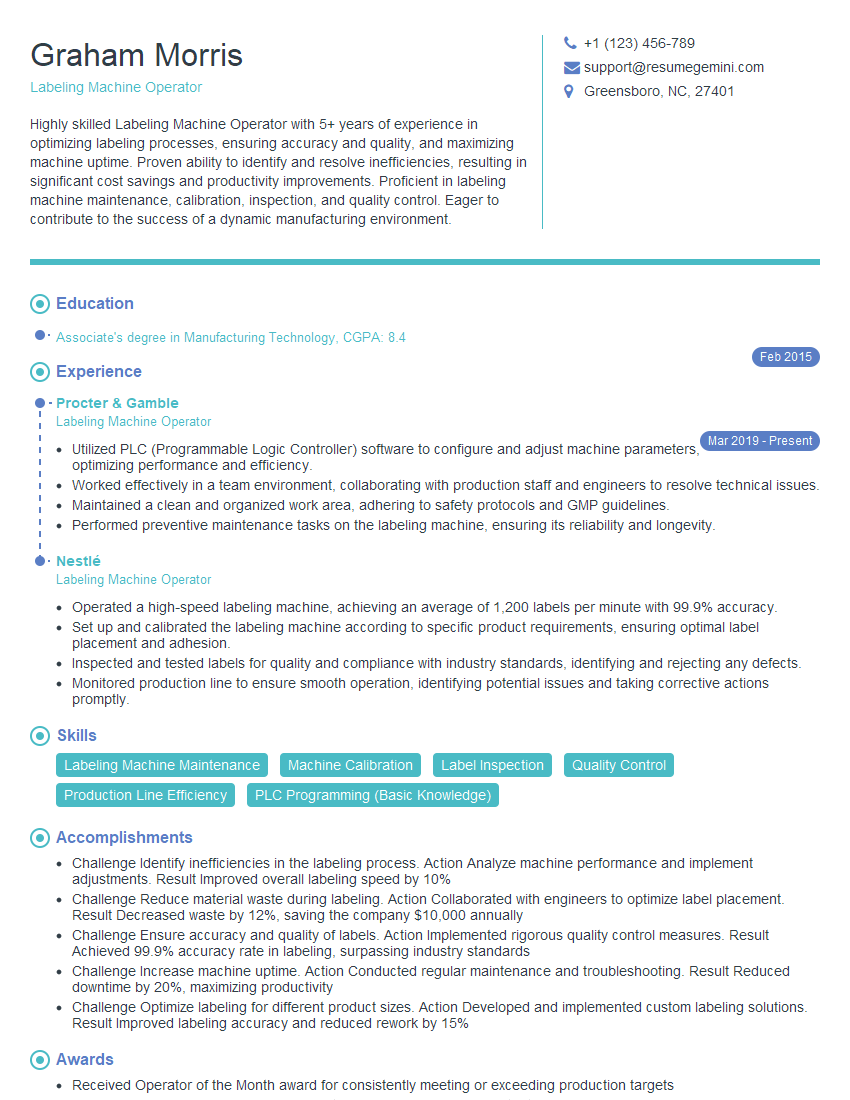

Graham Morris

Labeling Machine Operator

Summary

Highly skilled Labeling Machine Operator with 5+ years of experience in optimizing labeling processes, ensuring accuracy and quality, and maximizing machine uptime. Proven ability to identify and resolve inefficiencies, resulting in significant cost savings and productivity improvements. Proficient in labeling machine maintenance, calibration, inspection, and quality control. Eager to contribute to the success of a dynamic manufacturing environment.

Education

Associate’s degree in Manufacturing Technology

February 2015

Skills

- Labeling Machine Maintenance

- Machine Calibration

- Label Inspection

- Quality Control

- Production Line Efficiency

- PLC Programming (Basic Knowledge)

Work Experience

Labeling Machine Operator

- Utilized PLC (Programmable Logic Controller) software to configure and adjust machine parameters, optimizing performance and efficiency.

- Worked effectively in a team environment, collaborating with production staff and engineers to resolve technical issues.

- Maintained a clean and organized work area, adhering to safety protocols and GMP guidelines.

- Performed preventive maintenance tasks on the labeling machine, ensuring its reliability and longevity.

Labeling Machine Operator

- Operated a high-speed labeling machine, achieving an average of 1,200 labels per minute with 99.9% accuracy.

- Set up and calibrated the labeling machine according to specific product requirements, ensuring optimal label placement and adhesion.

- Inspected and tested labels for quality and compliance with industry standards, identifying and rejecting any defects.

- Monitored production line to ensure smooth operation, identifying potential issues and taking corrective actions promptly.

Accomplishments

- Challenge Identify inefficiencies in the labeling process. Action Analyze machine performance and implement adjustments. Result Improved overall labeling speed by 10%

- Challenge Reduce material waste during labeling. Action Collaborated with engineers to optimize label placement. Result Decreased waste by 12%, saving the company $10,000 annually

- Challenge Ensure accuracy and quality of labels. Action Implemented rigorous quality control measures. Result Achieved 99.9% accuracy rate in labeling, surpassing industry standards

- Challenge Increase machine uptime. Action Conducted regular maintenance and troubleshooting. Result Reduced downtime by 20%, maximizing productivity

- Challenge Optimize labeling for different product sizes. Action Developed and implemented custom labeling solutions. Result Improved labeling accuracy and reduced rework by 15%

Awards

- Received Operator of the Month award for consistently meeting or exceeding production targets

- Recognized for developing and implementing a new labeling process that increased efficiency by 15%

- Awarded Safety Star recognition for adhering to all safety protocols and maintaining a safe work environment

- Received Employee of the Quarter award for exceptional performance and dedication

Certificates

- OSHA 10Hour Safety Certification

- GMP Certification

- ISO 9001 Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Labeling Machine Operator

- Quantify your accomplishments with specific metrics and results.

- Highlight your skills in troubleshooting and problem-solving.

- Demonstrate your commitment to safety and quality control.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Labeling Machine Operator Resume

- Operate labeling machines to apply labels to products according to specified requirements.

- Monitor labeling processes to ensure accurate and consistent label placement, content, and quality.

- Inspect labels for defects and take corrective actions as necessary.

- Perform routine maintenance and calibration of labeling machines to ensure optimal performance.

- Troubleshoot and resolve labeling machine malfunctions to minimize downtime.

- Collaborate with engineers and production teams to optimize labeling processes and reduce waste.

- Maintain a clean and organized work area to ensure safety and efficiency.

Frequently Asked Questions (FAQ’s) For Labeling Machine Operator

What are the key skills required to be a successful Labeling Machine Operator?

Key skills include proficiency in labeling machine operation, maintenance, and calibration, as well as strong attention to detail, quality control, and problem-solving abilities.

What are the career advancement opportunities for Labeling Machine Operators?

With experience and additional training, Labeling Machine Operators can advance to roles such as Labeling Machine Supervisor, Production Supervisor, or Quality Control Inspector.

How can I improve my chances of getting hired as a Labeling Machine Operator?

Obtain formal training or certification in labeling machine operation and maintenance, gain hands-on experience through internships or volunteer work, and develop a strong understanding of quality control principles and practices.

What is the average salary for a Labeling Machine Operator?

The average salary for a Labeling Machine Operator in the United States is approximately $40,000 per year, according to Indeed.com.

What are the common challenges faced by Labeling Machine Operators?

Common challenges include maintaining high levels of accuracy and quality, optimizing labeling processes for efficiency, troubleshooting and resolving machine malfunctions, and ensuring compliance with safety and regulatory standards.

Is experience with specific labeling machine brands or models an advantage?

Yes, having experience with specific labeling machine brands or models can be an advantage, as it demonstrates your familiarity with the equipment and its unique features and requirements.

What are the safety precautions that Labeling Machine Operators should observe?

Labeling Machine Operators should always wear appropriate personal protective equipment, follow lockout/tagout procedures, and be aware of potential hazards such as moving machinery and electrical components.