Are you a seasoned Lacquer Dipping Machine Operator seeking a new career path? Discover our professionally built Lacquer Dipping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

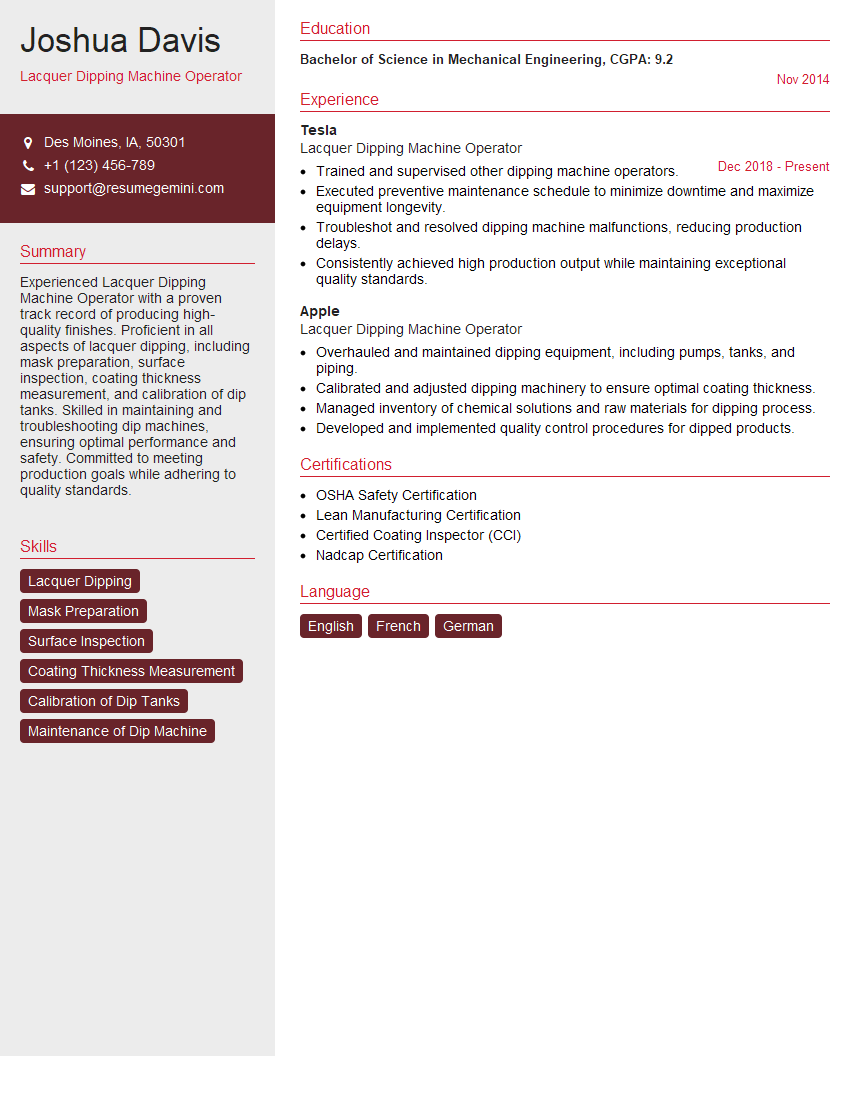

Joshua Davis

Lacquer Dipping Machine Operator

Summary

Experienced Lacquer Dipping Machine Operator with a proven track record of producing high-quality finishes. Proficient in all aspects of lacquer dipping, including mask preparation, surface inspection, coating thickness measurement, and calibration of dip tanks. Skilled in maintaining and troubleshooting dip machines, ensuring optimal performance and safety. Committed to meeting production goals while adhering to quality standards.

Education

Bachelor of Science in Mechanical Engineering

November 2014

Skills

- Lacquer Dipping

- Mask Preparation

- Surface Inspection

- Coating Thickness Measurement

- Calibration of Dip Tanks

- Maintenance of Dip Machine

Work Experience

Lacquer Dipping Machine Operator

- Trained and supervised other dipping machine operators.

- Executed preventive maintenance schedule to minimize downtime and maximize equipment longevity.

- Troubleshot and resolved dipping machine malfunctions, reducing production delays.

- Consistently achieved high production output while maintaining exceptional quality standards.

Lacquer Dipping Machine Operator

- Overhauled and maintained dipping equipment, including pumps, tanks, and piping.

- Calibrated and adjusted dipping machinery to ensure optimal coating thickness.

- Managed inventory of chemical solutions and raw materials for dipping process.

- Developed and implemented quality control procedures for dipped products.

Certificates

- OSHA Safety Certification

- Lean Manufacturing Certification

- Certified Coating Inspector (CCI)

- Nadcap Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lacquer Dipping Machine Operator

- Highlight your experience and skills in lacquer dipping, including specific techniques and equipment used.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact on the organization.

- Demonstrate your knowledge of industry standards and best practices for lacquer dipping.

- Showcase your ability to work independently and as part of a team in a fast-paced manufacturing environment.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Lacquer Dipping Machine Operator Resume

- Prepare masks to protect areas of the workpiece that should not be coated.

- Inspect surfaces to ensure they are clean and free of defects before dipping.

- Immerse workpieces in lacquer dip tanks, ensuring proper coating thickness.

- Measure coating thickness using a variety of techniques to ensure it meets specifications.

- Calibrate dip tanks regularly to maintain consistent coating quality.

- Maintain and troubleshoot dip machines, including pumps, filters, and heating elements.

- Follow safety protocols and wear appropriate personal protective equipment.

Frequently Asked Questions (FAQ’s) For Lacquer Dipping Machine Operator

What are the key skills required to be a successful Lacquer Dipping Machine Operator?

Key skills include lacquer dipping, mask preparation, surface inspection, coating thickness measurement, calibration of dip tanks, and maintenance of dip machines.

What are the typical working conditions for a Lacquer Dipping Machine Operator?

Lacquer Dipping Machine Operators typically work in a manufacturing environment, operating and maintaining dip machines. They may be exposed to chemicals and fumes, and must wear appropriate personal protective equipment.

What are the career opportunities for a Lacquer Dipping Machine Operator?

Lacquer Dipping Machine Operators may advance to positions such as Quality Control Inspector, Production Supervisor, or Manufacturing Manager.

What are the safety precautions that Lacquer Dipping Machine Operators should take?

Lacquer Dipping Machine Operators should wear appropriate personal protective equipment, including gloves, safety glasses, and respirators. They should also be aware of the potential hazards of working with chemicals and fumes.

What are the industry standards and best practices for lacquer dipping?

Industry standards and best practices for lacquer dipping include following manufacturer’s instructions, using proper equipment, and maintaining a clean work environment.

What are the common challenges faced by Lacquer Dipping Machine Operators?

Common challenges faced by Lacquer Dipping Machine Operators include ensuring consistent coating thickness, avoiding defects, and maintaining the quality of the finished product.

What are the key qualities of a successful Lacquer Dipping Machine Operator?

Key qualities of a successful Lacquer Dipping Machine Operator include attention to detail, manual dexterity, and the ability to work independently and as part of a team.

What are the different types of lacquer dipping machines?

Different types of lacquer dipping machines include manual, semi-automatic, and fully automatic machines. Each type of machine has its own advantages and disadvantages, and the choice of machine will depend on the specific application.