Are you a seasoned Ladle Mechanic seeking a new career path? Discover our professionally built Ladle Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

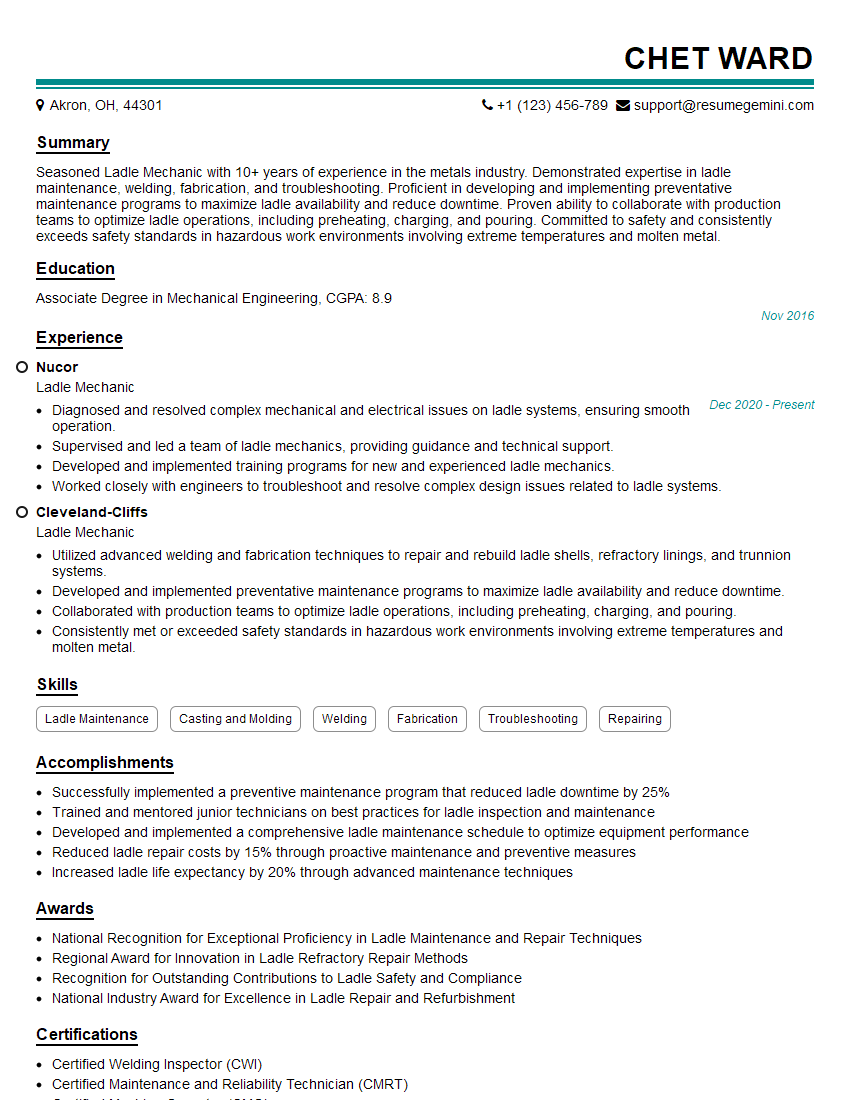

Chet Ward

Ladle Mechanic

Summary

Seasoned Ladle Mechanic with 10+ years of experience in the metals industry. Demonstrated expertise in ladle maintenance, welding, fabrication, and troubleshooting. Proficient in developing and implementing preventative maintenance programs to maximize ladle availability and reduce downtime. Proven ability to collaborate with production teams to optimize ladle operations, including preheating, charging, and pouring. Committed to safety and consistently exceeds safety standards in hazardous work environments involving extreme temperatures and molten metal.

Education

Associate Degree in Mechanical Engineering

November 2016

Skills

- Ladle Maintenance

- Casting and Molding

- Welding

- Fabrication

- Troubleshooting

- Repairing

Work Experience

Ladle Mechanic

- Diagnosed and resolved complex mechanical and electrical issues on ladle systems, ensuring smooth operation.

- Supervised and led a team of ladle mechanics, providing guidance and technical support.

- Developed and implemented training programs for new and experienced ladle mechanics.

- Worked closely with engineers to troubleshoot and resolve complex design issues related to ladle systems.

Ladle Mechanic

- Utilized advanced welding and fabrication techniques to repair and rebuild ladle shells, refractory linings, and trunnion systems.

- Developed and implemented preventative maintenance programs to maximize ladle availability and reduce downtime.

- Collaborated with production teams to optimize ladle operations, including preheating, charging, and pouring.

- Consistently met or exceeded safety standards in hazardous work environments involving extreme temperatures and molten metal.

Accomplishments

- Successfully implemented a preventive maintenance program that reduced ladle downtime by 25%

- Trained and mentored junior technicians on best practices for ladle inspection and maintenance

- Developed and implemented a comprehensive ladle maintenance schedule to optimize equipment performance

- Reduced ladle repair costs by 15% through proactive maintenance and preventive measures

- Increased ladle life expectancy by 20% through advanced maintenance techniques

Awards

- National Recognition for Exceptional Proficiency in Ladle Maintenance and Repair Techniques

- Regional Award for Innovation in Ladle Refractory Repair Methods

- Recognition for Outstanding Contributions to Ladle Safety and Compliance

- National Industry Award for Excellence in Ladle Repair and Refurbishment

Certificates

- Certified Welding Inspector (CWI)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Operator (CMO)

- National Institute for Metalworking Skills (NIMS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ladle Mechanic

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your skills in welding, fabrication, and troubleshooting.

- Emphasize your experience in developing and implementing preventative maintenance programs.

- Showcase your ability to work independently and as part of a team.

- Demonstrate your commitment to safety and adherence to industry standards.

Essential Experience Highlights for a Strong Ladle Mechanic Resume

- Repair and rebuild ladle shells, refractory linings, and trunnion systems using advanced welding and fabrication techniques.

- Develop and implement preventative maintenance programs to maximize ladle availability and reduce downtime.

- Collaborate with production teams to optimize ladle operations, including preheating, charging, and pouring.

- Diagnose and resolve complex mechanical and electrical issues on ladle systems, ensuring smooth operation.

- Supervise and lead a team of ladle mechanics, providing guidance and technical support.

- Work closely with engineers to troubleshoot and resolve complex design issues related to ladle systems.

Frequently Asked Questions (FAQ’s) For Ladle Mechanic

What is the role of a Ladle Mechanic?

A Ladle Mechanic is responsible for maintaining, repairing, and troubleshooting ladle systems, which are used to transport molten metal in the metals industry.

What skills are required to be a successful Ladle Mechanic?

Successful Ladle Mechanics typically have a strong background in welding, fabrication, and mechanical repair. They are also skilled in troubleshooting and problem-solving, and have a deep understanding of ladle systems.

What is the work environment of a Ladle Mechanic like?

Ladle Mechanics typically work in industrial settings, such as steel mills or foundries. They may be exposed to extreme temperatures, molten metal, and other hazardous materials.

What are the career prospects for a Ladle Mechanic?

Ladle Mechanics with experience and expertise can advance to supervisory or management roles. They may also specialize in a particular area of ladle maintenance, such as welding or fabrication.

What is the average salary of a Ladle Mechanic?

The average salary for a Ladle Mechanic in the United States is around $65,000 per year.

What are the educational requirements to become a Ladle Mechanic?

Most Ladle Mechanics have an associate degree in mechanical engineering or a related field.

What certifications are available for Ladle Mechanics?

Ladle Mechanics can obtain certifications from organizations such as the National Institute for Certification in Engineering Technologies (NICET) or the American Welding Society (AWS).