Are you a seasoned Ladle Patcher seeking a new career path? Discover our professionally built Ladle Patcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

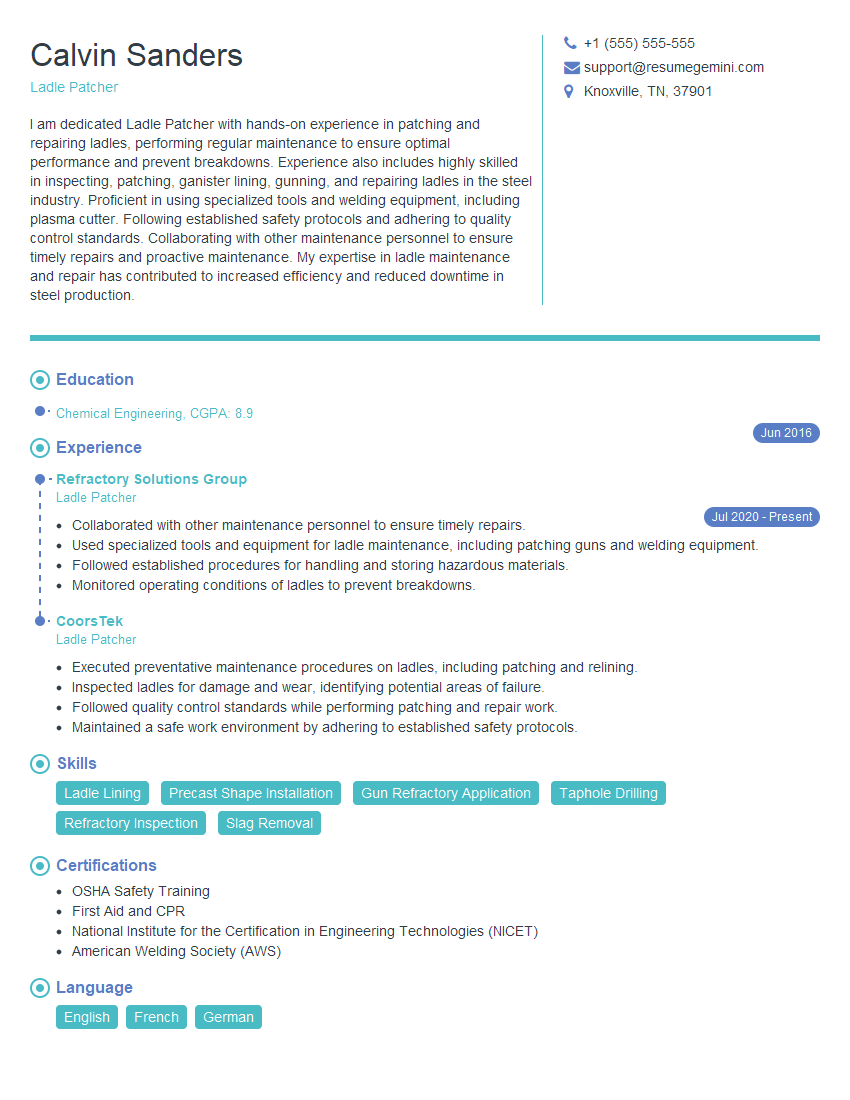

Calvin Sanders

Ladle Patcher

Summary

I am dedicated Ladle Patcher with hands-on experience in patching and repairing ladles, performing regular maintenance to ensure optimal performance and prevent breakdowns. Experience also includes highly skilled in inspecting, patching, ganister lining, gunning, and repairing ladles in the steel industry. Proficient in using specialized tools and welding equipment, including plasma cutter. Following established safety protocols and adhering to quality control standards. Collaborating with other maintenance personnel to ensure timely repairs and proactive maintenance. My expertise in ladle maintenance and repair has contributed to increased efficiency and reduced downtime in steel production.

Education

Chemical Engineering

June 2016

Skills

- Ladle Lining

- Precast Shape Installation

- Gun Refractory Application

- Taphole Drilling

- Refractory Inspection

- Slag Removal

Work Experience

Ladle Patcher

- Collaborated with other maintenance personnel to ensure timely repairs.

- Used specialized tools and equipment for ladle maintenance, including patching guns and welding equipment.

- Followed established procedures for handling and storing hazardous materials.

- Monitored operating conditions of ladles to prevent breakdowns.

Ladle Patcher

- Executed preventative maintenance procedures on ladles, including patching and relining.

- Inspected ladles for damage and wear, identifying potential areas of failure.

- Followed quality control standards while performing patching and repair work.

- Maintained a safe work environment by adhering to established safety protocols.

Certificates

- OSHA Safety Training

- First Aid and CPR

- National Institute for the Certification in Engineering Technologies (NICET)

- American Welding Society (AWS)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ladle Patcher

- Showcase your expertise in refractory lining, repair techniques, and quality control measures.

- Highlight your knowledge of different types of ladles.

- Emphasize your hands-on experience with specialized tools and equipment.

- Demonstrate your understanding of safety protocols and regulations.

Essential Experience Highlights for a Strong Ladle Patcher Resume

- Executed preventative maintenance procedures on ladles, including patching and relining.

- Inspected ladles for damage and wear, identifying potential areas of failure.

- Followed quality control standards while performing patching and repair work.

- Maintained a safe work environment by adhering to established safety protocols.

- Collaborated with other maintenance personnel to ensure timely repairs.

- Used specialized tools and equipment for ladle maintenance, including patching guns and welding equipment.

Frequently Asked Questions (FAQ’s) For Ladle Patcher

What are the key skills required to be a Ladle Patcher?

Ladle Patchers require a combination of technical skills and safety awareness. They should have expertise in refractory lining, repair techniques, and quality control measures. Additionally, they need to be familiar with different types of ladles and have hands-on experience with specialized tools and equipment. Moreover, adhering to safety protocols and regulations is crucial for the job.

What are the job responsibilities of a Ladle Patcher?

Ladle Patchers are responsible for inspecting ladles, identifying areas of damage or wear, and performing necessary repairs to maintain the integrity of the ladle. They use specialized tools and equipment, such as patching guns and welding equipment, to carry out repairs. Additionally, they ensure that quality control standards are met and safety protocols are followed during the repair process.

What are the career prospects for a Ladle Patcher?

Ladle Patchers can advance their careers by gaining experience and developing specialized skills. With time, they can move into supervisory roles or become experts in specific areas of ladle maintenance and repair. The steel industry offers various opportunities for growth and advancement for skilled Ladle Patchers.

What are the educational requirements to become a Ladle Patcher?

While there are no specific educational requirements to become a Ladle Patcher, many employers prefer candidates with a high school diploma or equivalent. Some may also require additional training or experience in refractory lining, welding, or related fields. Apprenticeships and on-the-job training programs can provide valuable hands-on experience for aspiring Ladle Patchers.

What is the work environment of a Ladle Patcher like?

Ladle Patchers typically work in industrial settings, such as steel mills or foundries. They may work in confined spaces or at heights, and they are often exposed to heat, noise, and hazardous materials. However, they also work in teams and have the opportunity to make a significant contribution to the production process.

What are the safety risks associated with being a Ladle Patcher?

Ladle Patchers work with heavy equipment and hazardous materials, so they must be aware of the potential risks and take appropriate safety precautions. They wear protective clothing and equipment, follow established safety protocols, and receive regular training to minimize the risk of accidents or injuries.