Are you a seasoned Ladle Repairer seeking a new career path? Discover our professionally built Ladle Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

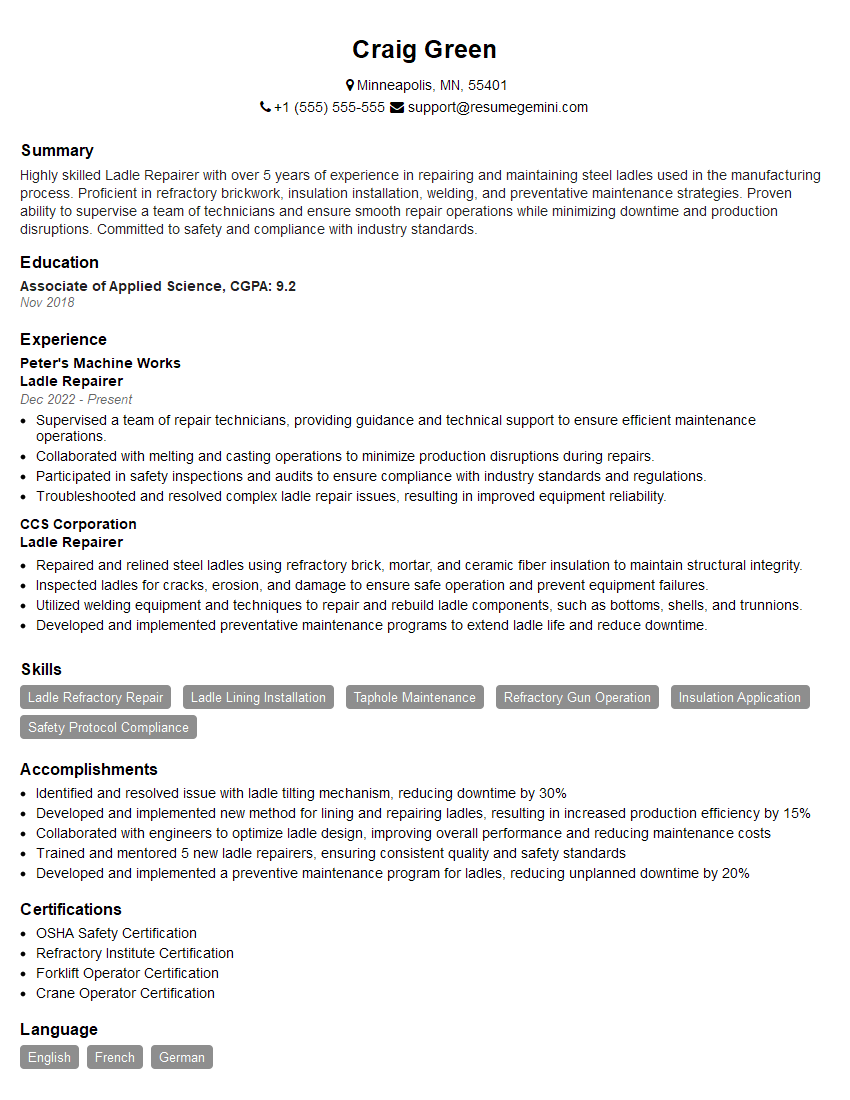

Craig Green

Ladle Repairer

Summary

Highly skilled Ladle Repairer with over 5 years of experience in repairing and maintaining steel ladles used in the manufacturing process. Proficient in refractory brickwork, insulation installation, welding, and preventative maintenance strategies. Proven ability to supervise a team of technicians and ensure smooth repair operations while minimizing downtime and production disruptions. Committed to safety and compliance with industry standards.

Education

Associate of Applied Science

November 2018

Skills

- Ladle Refractory Repair

- Ladle Lining Installation

- Taphole Maintenance

- Refractory Gun Operation

- Insulation Application

- Safety Protocol Compliance

Work Experience

Ladle Repairer

- Supervised a team of repair technicians, providing guidance and technical support to ensure efficient maintenance operations.

- Collaborated with melting and casting operations to minimize production disruptions during repairs.

- Participated in safety inspections and audits to ensure compliance with industry standards and regulations.

- Troubleshooted and resolved complex ladle repair issues, resulting in improved equipment reliability.

Ladle Repairer

- Repaired and relined steel ladles using refractory brick, mortar, and ceramic fiber insulation to maintain structural integrity.

- Inspected ladles for cracks, erosion, and damage to ensure safe operation and prevent equipment failures.

- Utilized welding equipment and techniques to repair and rebuild ladle components, such as bottoms, shells, and trunnions.

- Developed and implemented preventative maintenance programs to extend ladle life and reduce downtime.

Accomplishments

- Identified and resolved issue with ladle tilting mechanism, reducing downtime by 30%

- Developed and implemented new method for lining and repairing ladles, resulting in increased production efficiency by 15%

- Collaborated with engineers to optimize ladle design, improving overall performance and reducing maintenance costs

- Trained and mentored 5 new ladle repairers, ensuring consistent quality and safety standards

- Developed and implemented a preventive maintenance program for ladles, reducing unplanned downtime by 20%

Certificates

- OSHA Safety Certification

- Refractory Institute Certification

- Forklift Operator Certification

- Crane Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ladle Repairer

- Highlight your proficiency in ladle refractory repair, lining installation, and taphole maintenance.

- Emphasize your experience in welding and other repair techniques used in ladle maintenance.

- Quantify your accomplishments whenever possible, such as the number of ladles repaired or the percentage of downtime reduced.

- Showcase your ability to work independently and as part of a team, as well as your commitment to safety and industry standards.

- Consider including any additional skills or certifications that are relevant to the role, such as NDT or OSHA compliance.

Essential Experience Highlights for a Strong Ladle Repairer Resume

- Repaired and relined steel ladles using refractory brick, mortar, and ceramic fiber insulation to maintain structural integrity.

- Inspected ladles for cracks, erosion, and damage to ensure safe operation and prevent equipment failures.

- Utilized welding equipment and techniques to repair and rebuild ladle components, such as bottoms, shells, and trunnions.

- Developed and implemented preventative maintenance programs to extend ladle life and reduce downtime.

- Supervised a team of repair technicians, providing guidance and technical support to ensure efficient maintenance operations.

- Collaborated with melting and casting operations to minimize production disruptions during repairs.

- Participated in safety inspections and audits to ensure compliance with industry standards and regulations.

Frequently Asked Questions (FAQ’s) For Ladle Repairer

What are the primary duties of a Ladle Repairer?

The primary duties of a Ladle Repairer involve repairing and maintaining steel ladles used in manufacturing processes. This includes inspecting ladles for damage, performing repairs using refractory brickwork and welding techniques, installing insulation, and developing preventative maintenance programs.

What skills are required to become a Ladle Repairer?

To become a Ladle Repairer, you typically need a high school diploma or equivalent and experience in welding, refractory repair, or a related field. Strong knowledge of metallurgy and the ability to work independently and as part of a team are also essential.

What industries employ Ladle Repairers?

Ladle Repairers are primarily employed in the steel and metal manufacturing industries, where they play a crucial role in maintaining the equipment used in the production process.

What is the average salary of a Ladle Repairer?

The average salary of a Ladle Repairer in the United States is around $55,000 per year, according to Indeed. However, salaries may vary depending on experience, location, and employer.

What are the career prospects for Ladle Repairers?

Ladle Repairers with experience and a strong track record can advance to supervisory or management roles within their organizations. They may also specialize in specific areas of ladle repair or pursue further education to enhance their skills and knowledge.

Is it necessary to have a college degree to become a Ladle Repairer?

While a college degree is not typically required, many employers prefer candidates with an Associate’s Degree in Welding, Metallurgy, or a related field. However, on-the-job training and experience can also qualify individuals for this role.

What are the safety hazards associated with being a Ladle Repairer?

Working as a Ladle Repairer involves potential hazards such as exposure to heat, molten metal, fumes, and heavy equipment. Proper protective gear, adherence to safety protocols, and regular training are essential to minimize risks.

How can I improve my chances of getting hired as a Ladle Repairer?

To increase your chances of getting hired as a Ladle Repairer, focus on developing strong welding and refractory repair skills, completing relevant certifications, and gaining experience in the manufacturing industry. Networking, attending industry events, and tailoring your resume to specific job requirements can also be beneficial.