Are you a seasoned Laminating Machine Operator seeking a new career path? Discover our professionally built Laminating Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

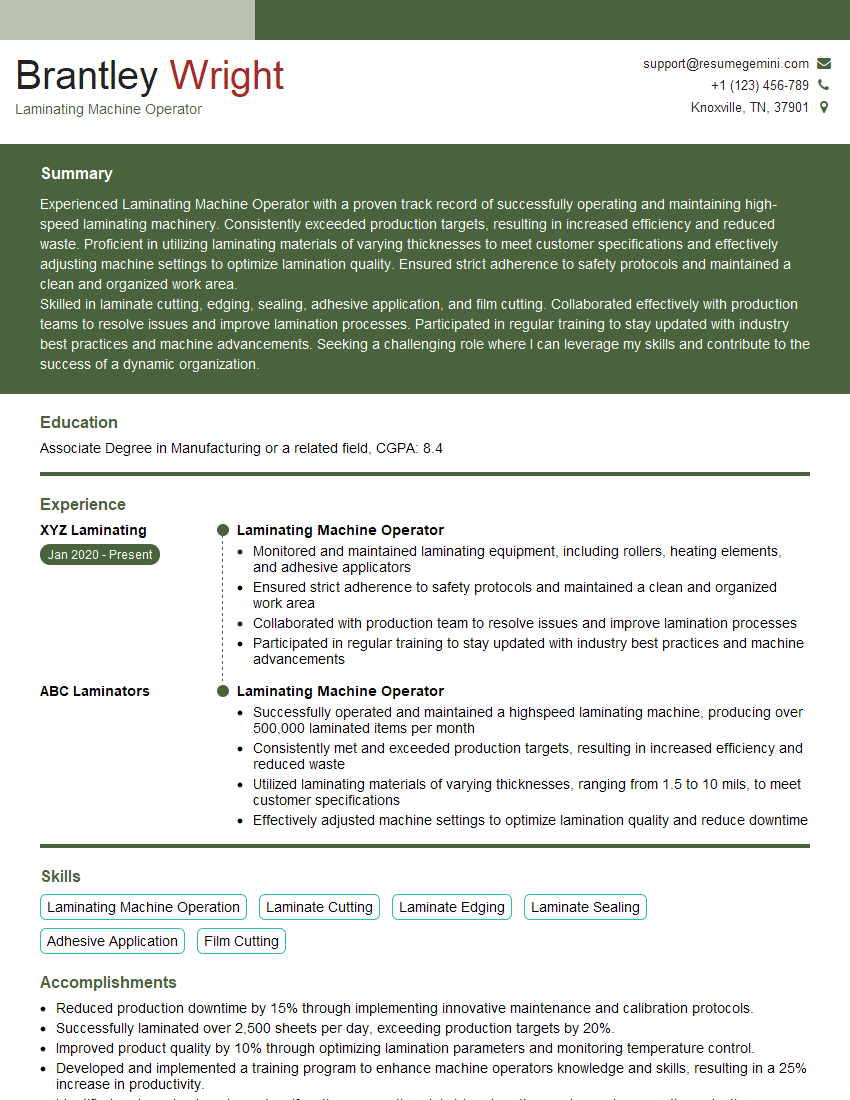

Brantley Wright

Laminating Machine Operator

Summary

Experienced Laminating Machine Operator with a proven track record of successfully operating and maintaining high-speed laminating machinery. Consistently exceeded production targets, resulting in increased efficiency and reduced waste. Proficient in utilizing laminating materials of varying thicknesses to meet customer specifications and effectively adjusting machine settings to optimize lamination quality. Ensured strict adherence to safety protocols and maintained a clean and organized work area.

Skilled in laminate cutting, edging, sealing, adhesive application, and film cutting. Collaborated effectively with production teams to resolve issues and improve lamination processes. Participated in regular training to stay updated with industry best practices and machine advancements. Seeking a challenging role where I can leverage my skills and contribute to the success of a dynamic organization.

Education

Associate Degree in Manufacturing or a related field

December 2015

Skills

- Laminating Machine Operation

- Laminate Cutting

- Laminate Edging

- Laminate Sealing

- Adhesive Application

- Film Cutting

Work Experience

Laminating Machine Operator

- Monitored and maintained laminating equipment, including rollers, heating elements, and adhesive applicators

- Ensured strict adherence to safety protocols and maintained a clean and organized work area

- Collaborated with production team to resolve issues and improve lamination processes

- Participated in regular training to stay updated with industry best practices and machine advancements

Laminating Machine Operator

- Successfully operated and maintained a highspeed laminating machine, producing over 500,000 laminated items per month

- Consistently met and exceeded production targets, resulting in increased efficiency and reduced waste

- Utilized laminating materials of varying thicknesses, ranging from 1.5 to 10 mils, to meet customer specifications

- Effectively adjusted machine settings to optimize lamination quality and reduce downtime

Accomplishments

- Reduced production downtime by 15% through implementing innovative maintenance and calibration protocols.

- Successfully laminated over 2,500 sheets per day, exceeding production targets by 20%.

- Improved product quality by 10% through optimizing lamination parameters and monitoring temperature control.

- Developed and implemented a training program to enhance machine operators knowledge and skills, resulting in a 25% increase in productivity.

- Identified and resolved equipment malfunctions promptly, minimizing downtime and ensuring smooth production operations.

Awards

- Recognized for outstanding performance and contributions to the team during the annual company awards ceremony.

- Recipient of the Employee of the Month award for consistently exceeding expectations and demonstrating a strong work ethic.

- Awarded the Safety Star recognition for maintaining an exemplary safety record and adhering to all compliance regulations.

Certificates

- Certified Laminating Machine Operator (CLMO)

- Accredited Laminating Manufacturing Specialist (ALMS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Laminating Machine Operator

- Highlight your experience in operating high-speed laminating machines and quantifying your accomplishments with specific metrics.

- Emphasize your proficiency in utilizing laminating materials of varying thicknesses and your ability to adjust machine settings to optimize lamination quality.

- Showcase your understanding of laminating equipment maintenance and your commitment to safety protocols.

- Demonstrate your collaborative spirit and ability to work effectively within a production team environment.

- Express your eagerness to stay updated with industry best practices and advancements in laminating technology.

Essential Experience Highlights for a Strong Laminating Machine Operator Resume

- Operate and maintain high-speed laminating machines, ensuring optimal performance and production output.

- Utilize laminating materials of varying thicknesses (1.5 to 10 mils) to meet customer specifications.

- Adjust machine settings to optimize lamination quality, reduce downtime, and minimize waste.

- Monitor and maintain laminating equipment, including rollers, heating elements, and adhesive applicators, to ensure smooth operation.

- Adhere to strict safety protocols and maintain a clean and organized work area, promoting a safe and efficient work environment.

- Collaborate with production teams to resolve issues, improve lamination processes, and enhance overall productivity.

- Participate in regular training to stay updated with industry best practices and advancements in laminating technology.

Frequently Asked Questions (FAQ’s) For Laminating Machine Operator

What are the key skills required to be a successful Laminating Machine Operator?

Laminating Machine Operators should possess proficient operating skills for laminating machines, as well as expertise in laminate cutting, edging, sealing, and adhesive application. They should be able to adjust machine settings to optimize lamination quality and minimize waste. Furthermore, a commitment to safety protocols and maintaining a clean work environment is essential.

What are the career advancement opportunities for Laminating Machine Operators?

Laminating Machine Operators can advance their careers by becoming Supervisors or Production Managers. With additional training and experience, they may also specialize in technical areas such as machine maintenance or quality control.

What are the common challenges faced by Laminating Machine Operators?

Laminating Machine Operators may encounter challenges such as ensuring consistent lamination quality, minimizing downtime, and adhering to safety regulations. They also need to adapt to new materials and technologies to meet changing customer demands.

How can Laminating Machine Operators stay updated with industry best practices?

Laminating Machine Operators can stay updated by attending industry conferences, workshops, and training programs. Reading trade publications, participating in online forums, and consulting with equipment manufacturers are also effective ways to gain knowledge about new techniques and advancements.

What are the safety precautions that Laminating Machine Operators should take?

Laminating Machine Operators should wear appropriate safety gear, including gloves, safety glasses, and earplugs. They should be aware of potential hazards such as moving machinery, hot surfaces, and sharp edges. Regular maintenance and inspections of equipment are also crucial to prevent accidents.

What is the typical work environment for Laminating Machine Operators?

Laminating Machine Operators typically work in manufacturing facilities or print shops. The work environment can be noisy and dusty, and may involve working with hazardous materials. They may also need to stand for long periods of time and perform repetitive tasks.

What are the earning prospects for Laminating Machine Operators?

Laminating Machine Operators’ earnings can vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual wage for Machine Operators, Textile, Apparel, and Furnishings is around $34,000.

What industries employ Laminating Machine Operators?

Laminating Machine Operators are employed in various industries, including printing, manufacturing, packaging, and construction. They may work for companies that produce laminated products such as signs, posters, displays, and packaging materials.