Are you a seasoned Lamination Assembler seeking a new career path? Discover our professionally built Lamination Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

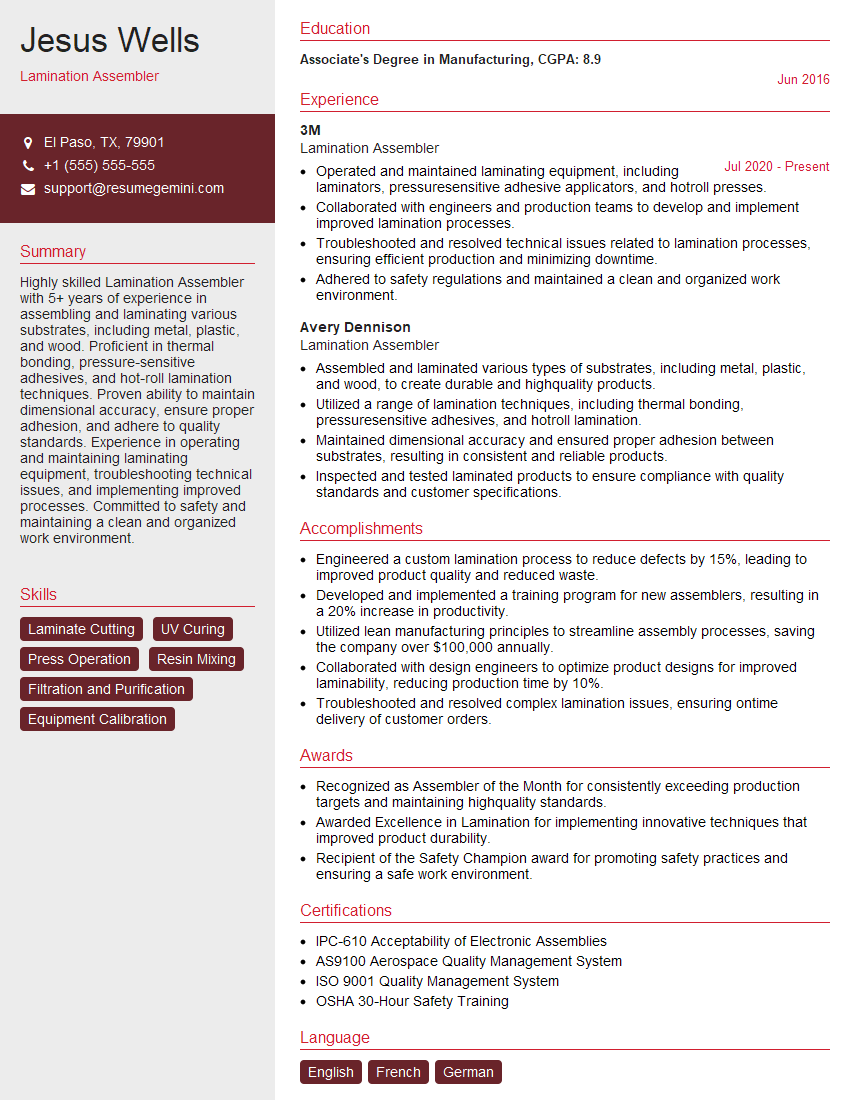

Jesus Wells

Lamination Assembler

Summary

Highly skilled Lamination Assembler with 5+ years of experience in assembling and laminating various substrates, including metal, plastic, and wood. Proficient in thermal bonding, pressure-sensitive adhesives, and hot-roll lamination techniques. Proven ability to maintain dimensional accuracy, ensure proper adhesion, and adhere to quality standards. Experience in operating and maintaining laminating equipment, troubleshooting technical issues, and implementing improved processes. Committed to safety and maintaining a clean and organized work environment.

Education

Associate’s Degree in Manufacturing

June 2016

Skills

- Laminate Cutting

- UV Curing

- Press Operation

- Resin Mixing

- Filtration and Purification

- Equipment Calibration

Work Experience

Lamination Assembler

- Operated and maintained laminating equipment, including laminators, pressuresensitive adhesive applicators, and hotroll presses.

- Collaborated with engineers and production teams to develop and implement improved lamination processes.

- Troubleshooted and resolved technical issues related to lamination processes, ensuring efficient production and minimizing downtime.

- Adhered to safety regulations and maintained a clean and organized work environment.

Lamination Assembler

- Assembled and laminated various types of substrates, including metal, plastic, and wood, to create durable and highquality products.

- Utilized a range of lamination techniques, including thermal bonding, pressuresensitive adhesives, and hotroll lamination.

- Maintained dimensional accuracy and ensured proper adhesion between substrates, resulting in consistent and reliable products.

- Inspected and tested laminated products to ensure compliance with quality standards and customer specifications.

Accomplishments

- Engineered a custom lamination process to reduce defects by 15%, leading to improved product quality and reduced waste.

- Developed and implemented a training program for new assemblers, resulting in a 20% increase in productivity.

- Utilized lean manufacturing principles to streamline assembly processes, saving the company over $100,000 annually.

- Collaborated with design engineers to optimize product designs for improved laminability, reducing production time by 10%.

- Troubleshooted and resolved complex lamination issues, ensuring ontime delivery of customer orders.

Awards

- Recognized as Assembler of the Month for consistently exceeding production targets and maintaining highquality standards.

- Awarded Excellence in Lamination for implementing innovative techniques that improved product durability.

- Recipient of the Safety Champion award for promoting safety practices and ensuring a safe work environment.

Certificates

- IPC-610 Acceptability of Electronic Assemblies

- AS9100 Aerospace Quality Management System

- ISO 9001 Quality Management System

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lamination Assembler

- Highlight your experience in assembling and laminating a variety of substrates.

- Demonstrate your knowledge of different lamination techniques and your ability to achieve high-quality results.

- Showcase your skills in operating and maintaining laminating equipment, as well as your ability to troubleshoot and resolve technical issues.

- Emphasize your commitment to safety and maintaining a clean and organized work environment.

- Quantify your accomplishments and use specific examples to demonstrate your impact on the company.

Essential Experience Highlights for a Strong Lamination Assembler Resume

- Assembling and laminating various types of substrates using thermal bonding, pressure-sensitive adhesives, and hot-roll lamination techniques

- Maintaining dimensional accuracy and ensuring proper adhesion between substrates to create durable and high-quality products

- Inspecting and testing laminated products to ensure compliance with quality standards and customer specifications

- Operating and maintaining laminating equipment, including laminators, pressure-sensitive adhesive applicators, and hot-roll presses

- Collaborating with engineers and production teams to develop and implement improved lamination processes

- Troubleshooted and resolved technical issues related to lamination processes, ensuring efficient production and minimizing downtime

- Adhered to safety regulations and maintained a clean and organized work environment

Frequently Asked Questions (FAQ’s) For Lamination Assembler

What are the primary responsibilities of a Lamination Assembler?

Lamination Assemblers are responsible for assembling and laminating various types of substrates to create durable and high-quality products. They must be proficient in different lamination techniques, operate and maintain laminating equipment, and ensure compliance with quality standards.

What skills are required to be a successful Lamination Assembler?

Successful Lamination Assemblers typically have experience in assembling and laminating a variety of substrates, knowledge of different lamination techniques, and proficiency in operating and maintaining laminating equipment. They should also be able to work independently and as part of a team, and adhere to safety regulations.

What industries hire Lamination Assemblers?

Lamination Assemblers are employed in a variety of industries, including manufacturing, construction, and packaging. They may work for companies that produce laminated products such as countertops, flooring, and signage.

What is the career outlook for Lamination Assemblers?

The career outlook for Lamination Assemblers is expected to be good in the coming years. The demand for laminated products is increasing in a variety of industries, and Lamination Assemblers with the right skills and experience will be in high demand.

What are the earning prospects for Lamination Assemblers?

The earning prospects for Lamination Assemblers vary depending on their experience, skills, and location. According to the U.S Bureau of Labor Statistics, the median annual salary for Assemblers and Fabricators is around $36,000.

What are the educational requirements to become a Lamination Assembler?

Most Lamination Assemblers have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in manufacturing or a related field.

What is the workplace of a Lamination Assembler like?

Lamination Assemblers typically work in manufacturing facilities or production plants. They may work in a variety of environments, including clean rooms, assembly lines, and warehouses.

Is there a certification available for Lamination Assemblers?

There is no formal certification available for Lamination Assemblers. However some companies may provide in-house training or certification programs for their employees.