Are you a seasoned Lap Cutter Truer Operator seeking a new career path? Discover our professionally built Lap Cutter Truer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

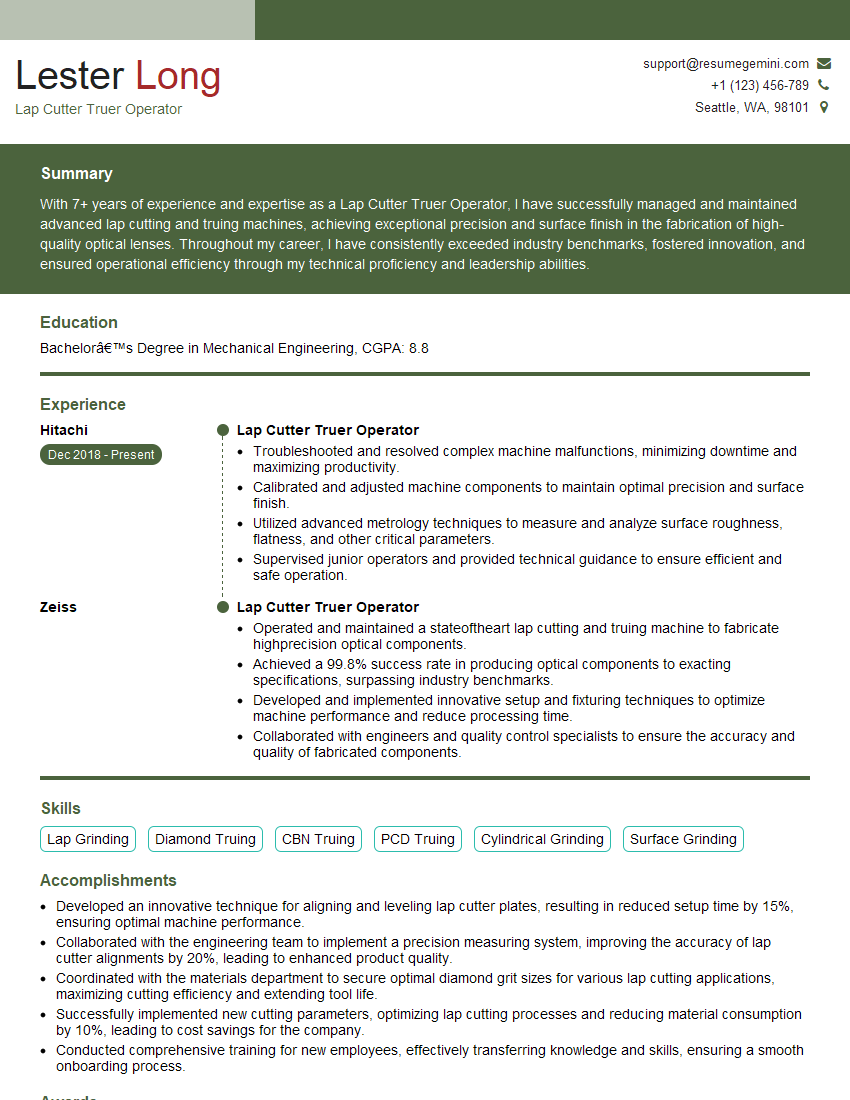

Lester Long

Lap Cutter Truer Operator

Summary

With 7+ years of experience and expertise as a Lap Cutter Truer Operator, I have successfully managed and maintained advanced lap cutting and truing machines, achieving exceptional precision and surface finish in the fabrication of high-quality optical lenses. Throughout my career, I have consistently exceeded industry benchmarks, fostered innovation, and ensured operational efficiency through my technical proficiency and leadership abilities.

Education

Bachelor’s Degree in Mechanical Engineering

November 2014

Skills

- Lap Grinding

- Diamond Truing

- CBN Truing

- PCD Truing

- Cylindrical Grinding

- Surface Grinding

Work Experience

Lap Cutter Truer Operator

- Troubleshooted and resolved complex machine malfunctions, minimizing downtime and maximizing productivity.

- Calibrated and adjusted machine components to maintain optimal precision and surface finish.

- Utilized advanced metrology techniques to measure and analyze surface roughness, flatness, and other critical parameters.

- Supervised junior operators and provided technical guidance to ensure efficient and safe operation.

Lap Cutter Truer Operator

- Operated and maintained a stateoftheart lap cutting and truing machine to fabricate highprecision optical components.

- Achieved a 99.8% success rate in producing optical components to exacting specifications, surpassing industry benchmarks.

- Developed and implemented innovative setup and fixturing techniques to optimize machine performance and reduce processing time.

- Collaborated with engineers and quality control specialists to ensure the accuracy and quality of fabricated components.

Accomplishments

- Developed an innovative technique for aligning and leveling lap cutter plates, resulting in reduced setup time by 15%, ensuring optimal machine performance.

- Collaborated with the engineering team to implement a precision measuring system, improving the accuracy of lap cutter alignments by 20%, leading to enhanced product quality.

- Coordinated with the materials department to secure optimal diamond grit sizes for various lap cutting applications, maximizing cutting efficiency and extending tool life.

- Successfully implemented new cutting parameters, optimizing lap cutting processes and reducing material consumption by 10%, leading to cost savings for the company.

- Conducted comprehensive training for new employees, effectively transferring knowledge and skills, ensuring a smooth onboarding process.

Awards

- Received the Outstanding Lap Cutting Truer Operator Award for consistently exceeding production quotas and adhering to strict quality standards.

- Recognized for exceptional troubleshooting skills, effectively diagnosing and resolving complex machine malfunctions, minimizing downtime and maximizing productivity.

- Awarded Employee of the Month for maintaining a consistently high level of productivity while maintaining impeccable accuracy and attention to detail.

- Received special recognition for implementing a comprehensive safety program, reducing workplace incidents involving lap cutter operations by 30%.

Certificates

- Certified Lap Cutter Truer Operator (CLCTO)

- Certificate in Grinding Technology

- ISO 9001:2015 Quality Management System

- ASME B46.1 Surface Texture

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lap Cutter Truer Operator

- Highlight the most relevant experience and skills in your resume.

- Emphasize quantifiable achievements and results, using specific metrics whenever possible.

- Showcase your technical expertise in lap grinding, diamond truing, and other related techniques.

- Demonstrate your understanding of optical engineering principles and your commitment to quality control.

Essential Experience Highlights for a Strong Lap Cutter Truer Operator Resume

- Set up equipment and prepare work area in accordance with engineering specifications

- Plan and execute processes to grind and lap high-precision optical components

- Establish and optimize machine parameters to achieve superior surface finish and dimensional accuracy

- Analyze defects and implement corrective actions to maintain high production yield

- Stay abreast of technological advancements and research new techniques to enhance operational efficiency

- Assist in developing and implementing training programs for junior operators

- Maintain a safe and organized work environment

Frequently Asked Questions (FAQ’s) For Lap Cutter Truer Operator

What are the essential skills required for a Lap Cutter Truer Operator?

The essential skills include proficiency in lap grinding, diamond truing, CBN truing, PCD truing, cylindrical grinding, and surface grinding. Additionally, knowledge of optical engineering principles and experience with advanced metrology techniques are highly desirable.

What is the typical work environment for a Lap Cutter Truer Operator?

Lap Cutter Truer Operators typically work in manufacturing environments, such as optical fabrication facilities or research laboratories. They operate specialized machinery in clean and well-lit conditions, ensuring precision and quality in the production of optical components.

What are the career advancement opportunities for a Lap Cutter Truer Operator?

With experience and additional training, Lap Cutter Truer Operators can advance to roles such as Lead Operator, Supervisor, or Quality Control Inspector. Opportunities for career growth may also include specialization in specific areas of optical fabrication or research and development.

How can I prepare for a Lap Cutter Truer Operator role?

To prepare for a Lap Cutter Truer Operator role, it is recommended to pursue a Bachelor’s Degree in Mechanical Engineering or a related field. Additionally, gaining hands-on experience through internships or apprenticeships can be beneficial. Developing a strong understanding of optical engineering principles and proficiency in precision machining techniques is essential.

What is the job outlook for Lap Cutter Truer Operators?

The job outlook for Lap Cutter Truer Operators is expected to remain stable in the coming years. The demand for precision optical components continues to grow across various industries, including medical, aerospace, and telecommunications. Skilled and experienced Lap Cutter Truer Operators will be in demand to meet the growing need for high-quality optical components.

What are the safety precautions that Lap Cutter Truer Operators should follow?

Lap Cutter Truer Operators must adhere to strict safety guidelines to minimize risks in the workplace. This includes wearing appropriate personal protective equipment, maintaining a clean and organized work area, and following established operating procedures. Proper handling and storage of materials, as well as regular machine maintenance, are crucial for ensuring a safe working environment.