Are you a seasoned Lap Grinder seeking a new career path? Discover our professionally built Lap Grinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

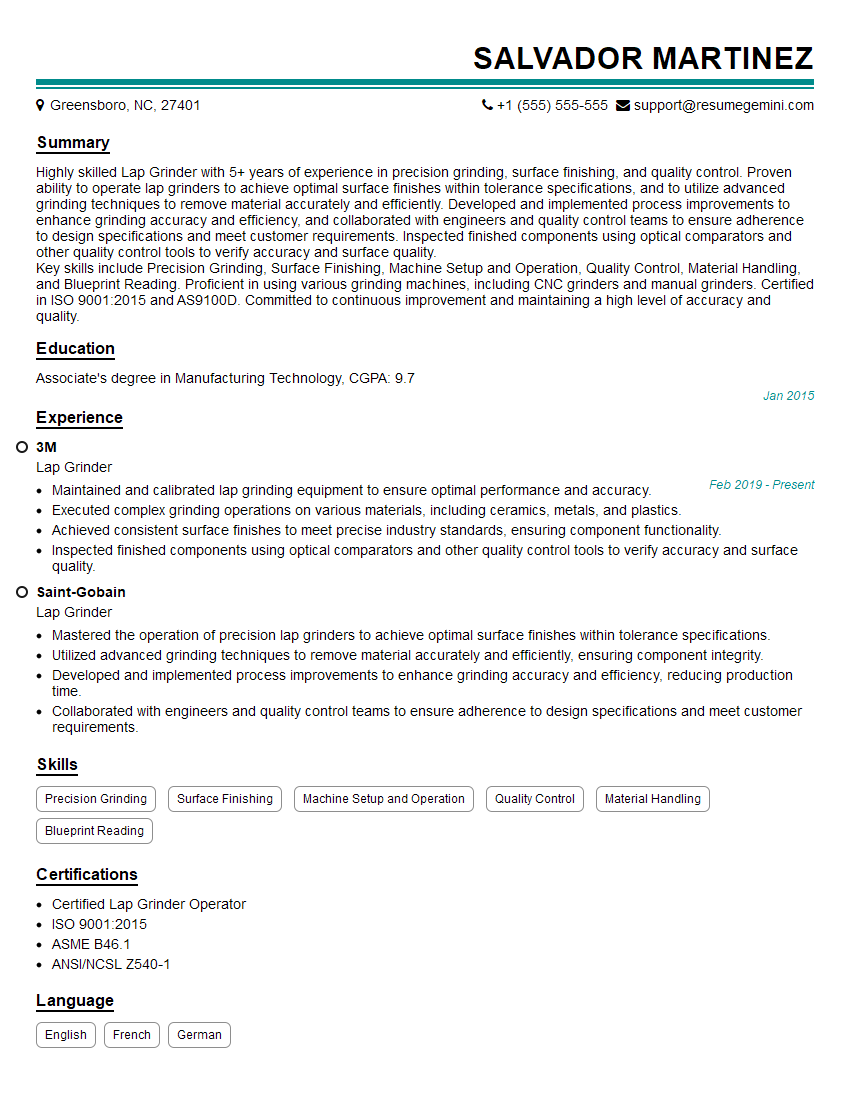

Salvador Martinez

Lap Grinder

Summary

Highly skilled Lap Grinder with 5+ years of experience in precision grinding, surface finishing, and quality control. Proven ability to operate lap grinders to achieve optimal surface finishes within tolerance specifications, and to utilize advanced grinding techniques to remove material accurately and efficiently. Developed and implemented process improvements to enhance grinding accuracy and efficiency, and collaborated with engineers and quality control teams to ensure adherence to design specifications and meet customer requirements. Inspected finished components using optical comparators and other quality control tools to verify accuracy and surface quality.

Key skills include Precision Grinding, Surface Finishing, Machine Setup and Operation, Quality Control, Material Handling, and Blueprint Reading. Proficient in using various grinding machines, including CNC grinders and manual grinders. Certified in ISO 9001:2015 and AS9100D. Committed to continuous improvement and maintaining a high level of accuracy and quality.

Education

Associate’s degree in Manufacturing Technology

January 2015

Skills

- Precision Grinding

- Surface Finishing

- Machine Setup and Operation

- Quality Control

- Material Handling

- Blueprint Reading

Work Experience

Lap Grinder

- Maintained and calibrated lap grinding equipment to ensure optimal performance and accuracy.

- Executed complex grinding operations on various materials, including ceramics, metals, and plastics.

- Achieved consistent surface finishes to meet precise industry standards, ensuring component functionality.

- Inspected finished components using optical comparators and other quality control tools to verify accuracy and surface quality.

Lap Grinder

- Mastered the operation of precision lap grinders to achieve optimal surface finishes within tolerance specifications.

- Utilized advanced grinding techniques to remove material accurately and efficiently, ensuring component integrity.

- Developed and implemented process improvements to enhance grinding accuracy and efficiency, reducing production time.

- Collaborated with engineers and quality control teams to ensure adherence to design specifications and meet customer requirements.

Certificates

- Certified Lap Grinder Operator

- ISO 9001:2015

- ASME B46.1

- ANSI/NCSL Z540-1

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lap Grinder

Highlight your skills and experience:

Make sure to list all of your relevant skills and experience in your resume, including any specific training or certifications you have.Showcase your precision:

Lap grinders are used to create very precise surfaces, so be sure to highlight your ability to achieve the desired results. Provide specific examples of projects you have worked on where you were able to achieve high levels of precision.Emphasize your quality control experience:

Lap grinders are used to create surfaces that meet specific quality standards, so be sure to highlight your experience in quality control. Provide specific examples of projects you have worked on where you were able to meet or exceed quality standards.Use keywords:

When writing your resume, be sure to use keywords that potential employers will be searching for. This will help your resume get noticed and increase your chances of getting an interview.Proofread your resume carefully:

Before you submit your resume, be sure to proofread it carefully for any errors. A well-written resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Lap Grinder Resume

- Operate precision lap grinders to achieve optimal surface finishes within tolerance specifications

- Utilize advanced grinding techniques to remove material accurately and efficiently, ensuring component integrity

- Develop and implement process improvements to enhance grinding accuracy and efficiency, reducing production time

- Collaborate with engineers and quality control teams to ensure adherence to design specifications and meet customer requirements

- Maintain and calibrate lap grinding equipment to ensure optimal performance and accuracy

- Inspect finished components using optical comparators and other quality control tools to verify accuracy and surface quality

- Execute complex grinding operations on various materials, including ceramics, metals, and plastics

Frequently Asked Questions (FAQ’s) For Lap Grinder

What is a Lap Grinder?

A lap grinder is a machine that uses a rotating abrasive wheel to grind and polish flat surfaces. Lap grinders are used in a variety of industries, including automotive, aerospace, and medical device manufacturing

What are the different types of Lap Grinders?

There are two main types of lap grinders: vertical and horizontal. Vertical lap grinders are used for grinding flat surfaces, while horizontal lap grinders are used for grinding cylindrical surfaces.

What are the benefits of using a Lap Grinder?

Lap grinders offer a number of benefits, including:

- High precision: Lap grinders can produce very precise surfaces, with tolerances of up to 0.0001 inches.

- Good surface finish: Lap grinders can produce a very smooth surface finish, with a roughness average (Ra) of less than 0.1 microns.

- Versatility: Lap grinders can be used to grind a variety of materials, including metals, ceramics, and plastics.

What are the applications of Lap Grinders?

Lap grinders are used in a variety of applications, including:

- Automotive: Lap grinders are used to grind flat surfaces on engine components, such as pistons and cylinder heads.

- Aerospace: Lap grinders are used to grind flat surfaces on aircraft components, such as wings and fuselages.

- Medical device manufacturing: Lap grinders are used to grind flat surfaces on medical devices, such as implants and surgical instruments.

What are the challenges of using a Lap Grinder?

There are a number of challenges associated with using a lap grinder, including:

- Precision: Lap grinders require a high level of precision, and operators must be skilled in order to produce accurate results.

- Surface finish: Lap grinders can produce a very smooth surface finish, but it can be difficult to achieve a consistent finish across the entire surface.

- Material removal: Lap grinders can remove material very quickly, but it is important to control the rate of material removal to avoid damaging the workpiece.

What are the safety precautions that should be taken when using a Lap Grinder?

A number of safety precautions should be taken when using a lap grinder, including:

- Wear appropriate safety gear, including eye protection, gloves, and a respirator.

- Ensure that the lap grinder is properly guarded.

- Never operate a lap grinder without proper training.

- Be aware of the potential for flying debris and take steps to protect yourself and others.

What are the maintenance requirements for a Lap Grinder?

Lap grinders require regular maintenance to ensure optimal performance and safety. Maintenance tasks include:

- Cleaning the lap grinder regularly.

- Inspecting the lap grinder for wear and tear.

- Lubricating the lap grinder according to the manufacturer’s instructions.

What are the troubleshooting tips for a Lap Grinder?

If you are experiencing problems with your lap grinder, there are a number of troubleshooting tips you can try:

- Check the power supply to ensure that the lap grinder is receiving power.

- Check the lap grinder for any loose or damaged parts.

- Clean the lap grinder to remove any debris that may be causing the problem.

- If you are still experiencing problems, consult the manufacturer’s instructions or contact a qualified technician.