Are you a seasoned Lap Machine Operator seeking a new career path? Discover our professionally built Lap Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

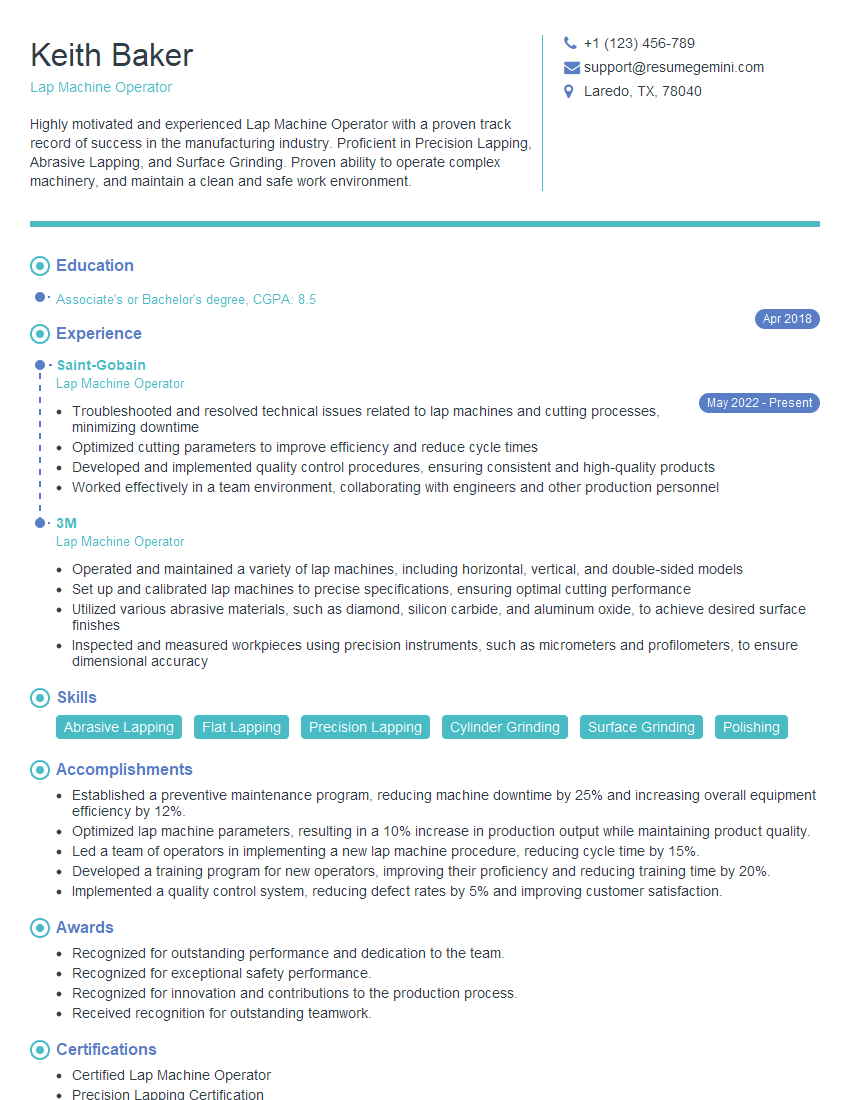

Keith Baker

Lap Machine Operator

Summary

Highly motivated and experienced Lap Machine Operator with a proven track record of success in the manufacturing industry. Proficient in Precision Lapping, Abrasive Lapping, and Surface Grinding. Proven ability to operate complex machinery, and maintain a clean and safe work environment.

Education

Associate’s or Bachelor’s degree

April 2018

Skills

- Abrasive Lapping

- Flat Lapping

- Precision Lapping

- Cylinder Grinding

- Surface Grinding

- Polishing

Work Experience

Lap Machine Operator

- Troubleshooted and resolved technical issues related to lap machines and cutting processes, minimizing downtime

- Optimized cutting parameters to improve efficiency and reduce cycle times

- Developed and implemented quality control procedures, ensuring consistent and high-quality products

- Worked effectively in a team environment, collaborating with engineers and other production personnel

Lap Machine Operator

- Operated and maintained a variety of lap machines, including horizontal, vertical, and double-sided models

- Set up and calibrated lap machines to precise specifications, ensuring optimal cutting performance

- Utilized various abrasive materials, such as diamond, silicon carbide, and aluminum oxide, to achieve desired surface finishes

- Inspected and measured workpieces using precision instruments, such as micrometers and profilometers, to ensure dimensional accuracy

Accomplishments

- Established a preventive maintenance program, reducing machine downtime by 25% and increasing overall equipment efficiency by 12%.

- Optimized lap machine parameters, resulting in a 10% increase in production output while maintaining product quality.

- Led a team of operators in implementing a new lap machine procedure, reducing cycle time by 15%.

- Developed a training program for new operators, improving their proficiency and reducing training time by 20%.

- Implemented a quality control system, reducing defect rates by 5% and improving customer satisfaction.

Awards

- Recognized for outstanding performance and dedication to the team.

- Recognized for exceptional safety performance.

- Recognized for innovation and contributions to the production process.

- Received recognition for outstanding teamwork.

Certificates

- Certified Lap Machine Operator

- Precision Lapping Certification

- ISO 9001 Certification

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lap Machine Operator

- Highlight your experience in operating lap machines, especially if you have experience with specific types of machines or materials.

- Showcase your knowledge of lapping techniques and processes, such as abrasive lapping, flat lapping, and precision lapping.

- Emphasize your ability to maintain and troubleshoot lap machines to ensure optimal performance.

- Include any certifications or training you have received related to lap machine operation or manufacturing processes

Essential Experience Highlights for a Strong Lap Machine Operator Resume

- Operate lap machines to grind and polish surfaces to specified dimensions and tolerances.

- Set up and adjust machines for different jobs, including selecting the correct abrasives and coolants.

- Monitor the progress of the lapping process and make adjustments as necessary to ensure quality.

- Maintain and clean lap machines and work area to ensure optimal performance.

- Inspect finished parts to ensure they meet specifications.

- Troubleshoot and resolve machine problems to minimize downtime.

- Follow safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Lap Machine Operator

What are the different types of lap machines?

There are various types of lap machines, including flat lap machines, cylindrical lap machines, and planetary lap machines. Flat lap machines are used for flat surfaces, cylindrical lap machines for cylindrical surfaces, and planetary lap machines for complex shapes.

What are the key skills required for a Lap Machine Operator?

Key skills for a Lap Machine Operator include proficiency in lapping techniques, machine operation, maintenance, and troubleshooting. Additionally, attention to detail, precision, and a commitment to quality are essential.

What is the work environment of a Lap Machine Operator like?

Lap Machine Operators typically work in manufacturing environments, operating machines in workshops or production facilities. The work can be physically demanding and may involve exposure to noise, dust, and chemicals. Safety protocols must be followed to ensure a safe working environment.

What are the career prospects for a Lap Machine Operator?

Lap Machine Operators can advance their careers by gaining experience and developing their skills. They may become supervisors or managers, or specialize in specific types of lapping or manufacturing processes. With additional training or education, they may also transition to related roles in quality control or engineering.