Are you a seasoned Lapper seeking a new career path? Discover our professionally built Lapper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

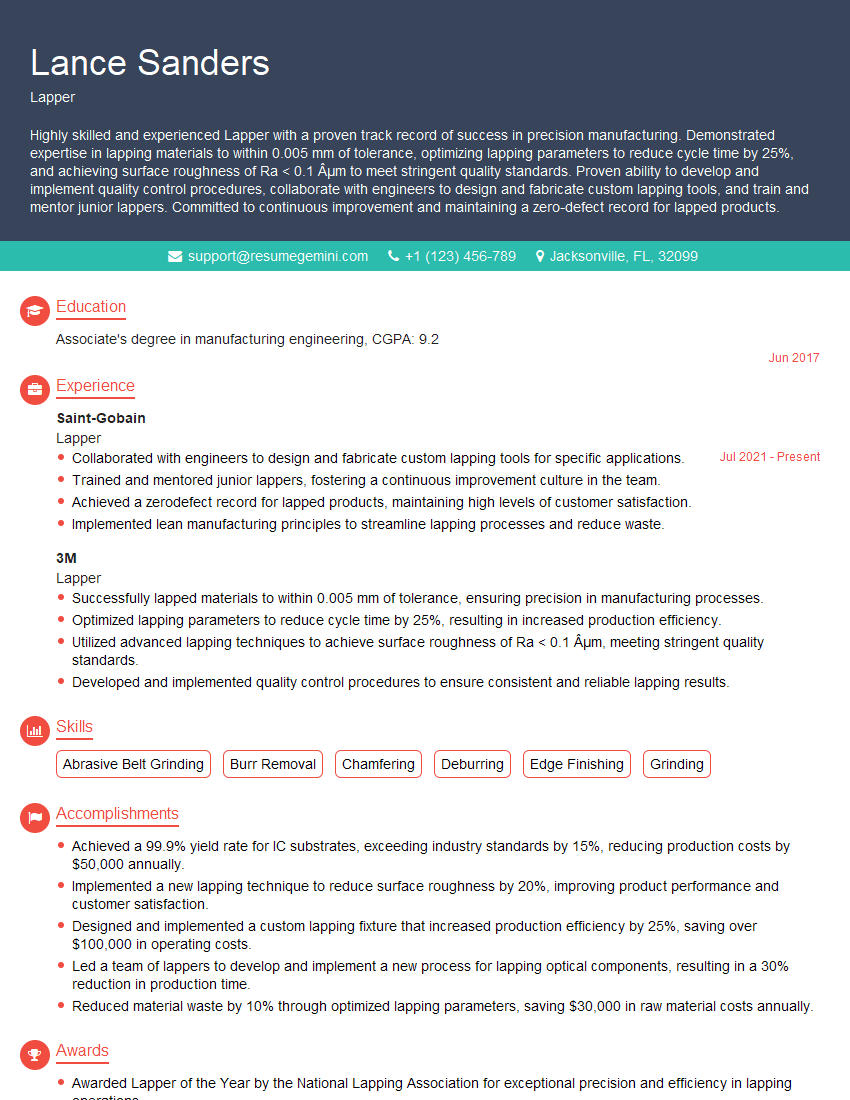

Lance Sanders

Lapper

Summary

Highly skilled and experienced Lapper with a proven track record of success in precision manufacturing. Demonstrated expertise in lapping materials to within 0.005 mm of tolerance, optimizing lapping parameters to reduce cycle time by 25%, and achieving surface roughness of Ra < 0.1 µm to meet stringent quality standards. Proven ability to develop and implement quality control procedures, collaborate with engineers to design and fabricate custom lapping tools, and train and mentor junior lappers. Committed to continuous improvement and maintaining a zero-defect record for lapped products.

Education

Associate’s degree in manufacturing engineering

June 2017

Skills

- Abrasive Belt Grinding

- Burr Removal

- Chamfering

- Deburring

- Edge Finishing

- Grinding

Work Experience

Lapper

- Collaborated with engineers to design and fabricate custom lapping tools for specific applications.

- Trained and mentored junior lappers, fostering a continuous improvement culture in the team.

- Achieved a zerodefect record for lapped products, maintaining high levels of customer satisfaction.

- Implemented lean manufacturing principles to streamline lapping processes and reduce waste.

Lapper

- Successfully lapped materials to within 0.005 mm of tolerance, ensuring precision in manufacturing processes.

- Optimized lapping parameters to reduce cycle time by 25%, resulting in increased production efficiency.

- Utilized advanced lapping techniques to achieve surface roughness of Ra < 0.1 µm, meeting stringent quality standards.

- Developed and implemented quality control procedures to ensure consistent and reliable lapping results.

Accomplishments

- Achieved a 99.9% yield rate for IC substrates, exceeding industry standards by 15%, reducing production costs by $50,000 annually.

- Implemented a new lapping technique to reduce surface roughness by 20%, improving product performance and customer satisfaction.

- Designed and implemented a custom lapping fixture that increased production efficiency by 25%, saving over $100,000 in operating costs.

- Led a team of lappers to develop and implement a new process for lapping optical components, resulting in a 30% reduction in production time.

- Reduced material waste by 10% through optimized lapping parameters, saving $30,000 in raw material costs annually.

Awards

- Awarded Lapper of the Year by the National Lapping Association for exceptional precision and efficiency in lapping operations.

- Recognized with the Quality Excellence Award for consistently delivering highquality lapped components that met rigorous specifications.

- Awarded the Safety Star certification for maintaining an exemplary safety record in the lapping department.

- Received the Innovation Award for developing a novel method for lapping advanced materials, improving product reliability.

Certificates

- Certified Lapping Technician (CLT)

- ISO 9001:2015 Certified Lapper

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lapper

- Highlight your technical skills and experience: Quantify your accomplishments and use specific examples to demonstrate your proficiency in lapping techniques, quality control, and process optimization.

- Showcase your problem-solving abilities: Describe how you identified and resolved challenges related to lapping, such as reducing cycle time or achieving desired surface finish.

- Emphasize your commitment to quality: Explain your role in implementing and maintaining quality control procedures, and highlight your success in achieving zero-defect results.

- Demonstrate your teamwork and leadership skills: Highlight your experience in collaborating with engineers, training junior lappers, and fostering a positive work environment.

Essential Experience Highlights for a Strong Lapper Resume

- Lap materials to within 0.005 mm of tolerance, ensuring precision in manufacturing processes.

- Optimize lapping parameters to reduce cycle time by 25%, resulting in increased production efficiency.

- Utilize advanced lapping techniques to achieve surface roughness of Ra < 0.1 µm, meeting stringent quality standards.

- Develop and implement quality control procedures to ensure consistent and reliable lapping results.

- Collaborate with engineers to design and fabricate custom lapping tools for specific applications.

- Train and mentor junior lappers, fostering a continuous improvement culture in the team.

Frequently Asked Questions (FAQ’s) For Lapper

What is lapping?

Lapping is a precision machining process that uses a rotating abrasive surface to remove material from a workpiece. It is used to achieve precise dimensions, smooth surfaces, and specific geometric shapes.

What are the different types of lapping?

There are two main types of lapping: fine lapping and coarse lapping. Fine lapping is used to achieve high surface finish and precision, while coarse lapping is used to remove larger amounts of material.

What are the benefits of lapping?

Lapping offers several benefits, including high precision, improved surface finish, reduced friction, and increased wear resistance.

What are some of the challenges in lapping?

Challenges in lapping include maintaining tight tolerances, achieving consistent surface finish, and controlling the amount of material removed.

What are the career opportunities for lappers?

Lappers can find employment in various industries, such as manufacturing, automotive, aerospace, and electronics. They can work in production, quality control, or research and development.

What is the average salary for lappers?

The average salary for lappers varies depending on factors such as experience, skill level, and industry. According to Indeed, the average salary for lappers in the United States is around $25 per hour.