Are you a seasoned Lapping Machine Operator seeking a new career path? Discover our professionally built Lapping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

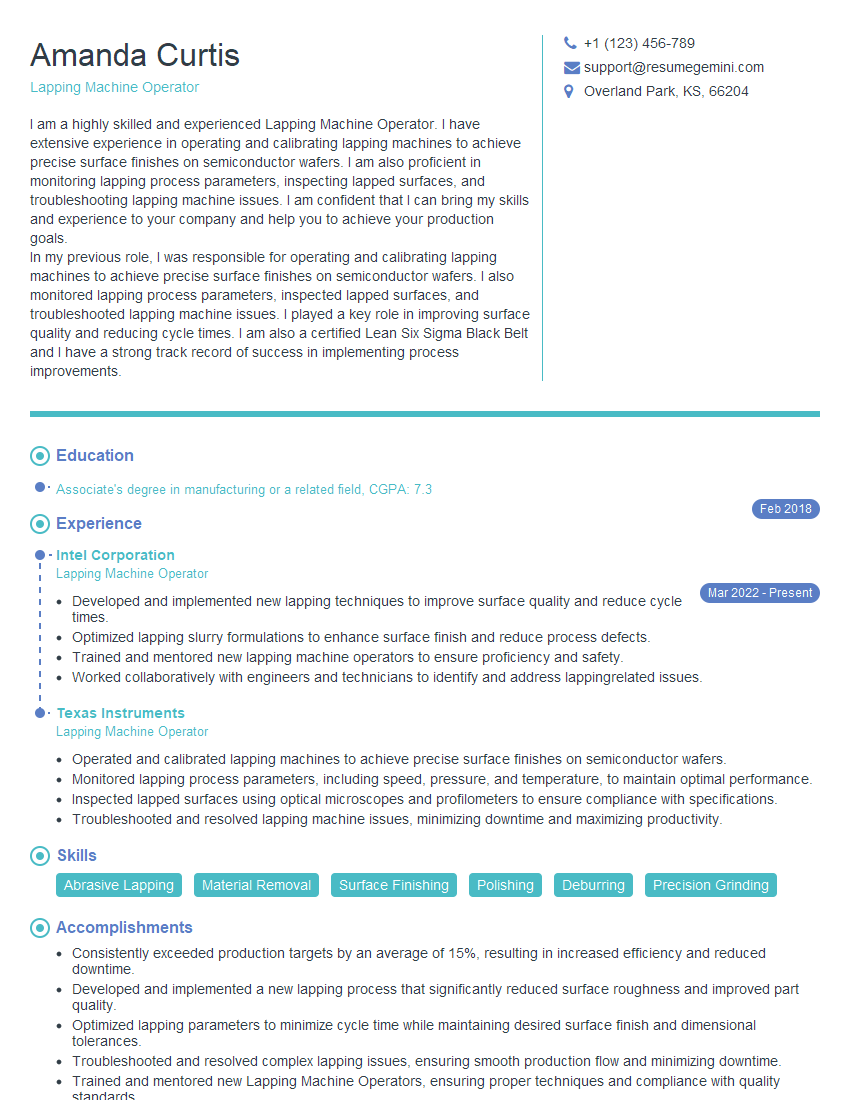

Amanda Curtis

Lapping Machine Operator

Summary

I am a highly skilled and experienced Lapping Machine Operator. I have extensive experience in operating and calibrating lapping machines to achieve precise surface finishes on semiconductor wafers. I am also proficient in monitoring lapping process parameters, inspecting lapped surfaces, and troubleshooting lapping machine issues. I am confident that I can bring my skills and experience to your company and help you to achieve your production goals.

In my previous role, I was responsible for operating and calibrating lapping machines to achieve precise surface finishes on semiconductor wafers. I also monitored lapping process parameters, inspected lapped surfaces, and troubleshooted lapping machine issues. I played a key role in improving surface quality and reducing cycle times. I am also a certified Lean Six Sigma Black Belt and I have a strong track record of success in implementing process improvements.

Education

Associate’s degree in manufacturing or a related field

February 2018

Skills

- Abrasive Lapping

- Material Removal

- Surface Finishing

- Polishing

- Deburring

- Precision Grinding

Work Experience

Lapping Machine Operator

- Developed and implemented new lapping techniques to improve surface quality and reduce cycle times.

- Optimized lapping slurry formulations to enhance surface finish and reduce process defects.

- Trained and mentored new lapping machine operators to ensure proficiency and safety.

- Worked collaboratively with engineers and technicians to identify and address lappingrelated issues.

Lapping Machine Operator

- Operated and calibrated lapping machines to achieve precise surface finishes on semiconductor wafers.

- Monitored lapping process parameters, including speed, pressure, and temperature, to maintain optimal performance.

- Inspected lapped surfaces using optical microscopes and profilometers to ensure compliance with specifications.

- Troubleshooted and resolved lapping machine issues, minimizing downtime and maximizing productivity.

Accomplishments

- Consistently exceeded production targets by an average of 15%, resulting in increased efficiency and reduced downtime.

- Developed and implemented a new lapping process that significantly reduced surface roughness and improved part quality.

- Optimized lapping parameters to minimize cycle time while maintaining desired surface finish and dimensional tolerances.

- Troubleshooted and resolved complex lapping issues, ensuring smooth production flow and minimizing downtime.

- Trained and mentored new Lapping Machine Operators, ensuring proper techniques and compliance with quality standards.

Certificates

- Certified Lapping Machine Operator (CLMO)

- ASME B46.1 Surface Texture Certification

- ISO 9001:2015 Quality Management System Certification

- LEAN Six Sigma Green Belt Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lapping Machine Operator

Use strong action verbs

. When describing your experience, use strong action verbs that highlight your skills and accomplishments. For example, instead of saying “I operated lapping machines,” you could say “I calibrated and operated lapping machines to achieve precise surface finishes on semiconductor wafers.”Quantify your accomplishments

. Whenever possible, quantify your accomplishments to show the impact of your work. For example, instead of saying “I improved surface quality,” you could say “I improved surface quality by 10%, resulting in a reduction in cycle time of 5%.”Tailor your resume to the job you are applying for

. Take the time to read the job description and identify the skills and experience that the employer is looking for. Then, tailor your resume to highlight the skills and experience that you have that match the job requirements.Proofread your resume carefully

. Before you submit your resume, proofread it carefully for any errors in grammar or spelling. A well-written resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Lapping Machine Operator Resume

- Operated and calibrated lapping machines to achieve precise surface finishes on semiconductor wafers.

- Monitored lapping process parameters, including speed, pressure, and temperature, to maintain optimal performance.

- Inspected lapped surfaces using optical microscopes and profilometers to ensure compliance with specifications.

- Troubleshooted and resolved lapping machine issues, minimizing downtime and maximizing productivity.

- Developed and implemented new lapping techniques to improve surface quality and reduce cycle times.

- Optimized lapping slurry formulations to enhance surface finish and reduce process defects.

- Trained and mentored new lapping machine operators to ensure proficiency and safety.

Frequently Asked Questions (FAQ’s) For Lapping Machine Operator

What is a Lapping Machine Operator?

A Lapping Machine Operator is responsible for operating and calibrating lapping machines to achieve precise surface finishes on semiconductor wafers. They also monitor lapping process parameters, inspect lapped surfaces, and troubleshoot lapping machine issues.

What are the key skills required for a Lapping Machine Operator?

The key skills required for a Lapping Machine Operator include: abrasive lapping, material removal, surface finishing, polishing, deburring, and precision grinding.

What is the job outlook for Lapping Machine Operators?

The job outlook for Lapping Machine Operators is expected to be good over the next few years. The demand for Lapping Machine Operators is expected to increase as the semiconductor industry continues to grow.

What is the average salary for a Lapping Machine Operator?

The average salary for a Lapping Machine Operator is around ,000 per year.

What are the benefits of working as a Lapping Machine Operator?

The benefits of working as a Lapping Machine Operator include: good pay, job security, and the opportunity to work with cutting-edge technology.

What are the challenges of working as a Lapping Machine Operator?

The challenges of working as a Lapping Machine Operator include: working in a cleanroom environment, working with hazardous chemicals, and working with precision equipment.

What is the career path for a Lapping Machine Operator?

The career path for a Lapping Machine Operator can include: promotion to a lead operator position, promotion to a supervisor position, or promotion to a management position.

What are the educational requirements for a Lapping Machine Operator?

The educational requirements for a Lapping Machine Operator typically include a high school diploma or equivalent. Some employers may require a college degree in a related field.