Are you a seasoned Lapping Machine Set-Up Operator seeking a new career path? Discover our professionally built Lapping Machine Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

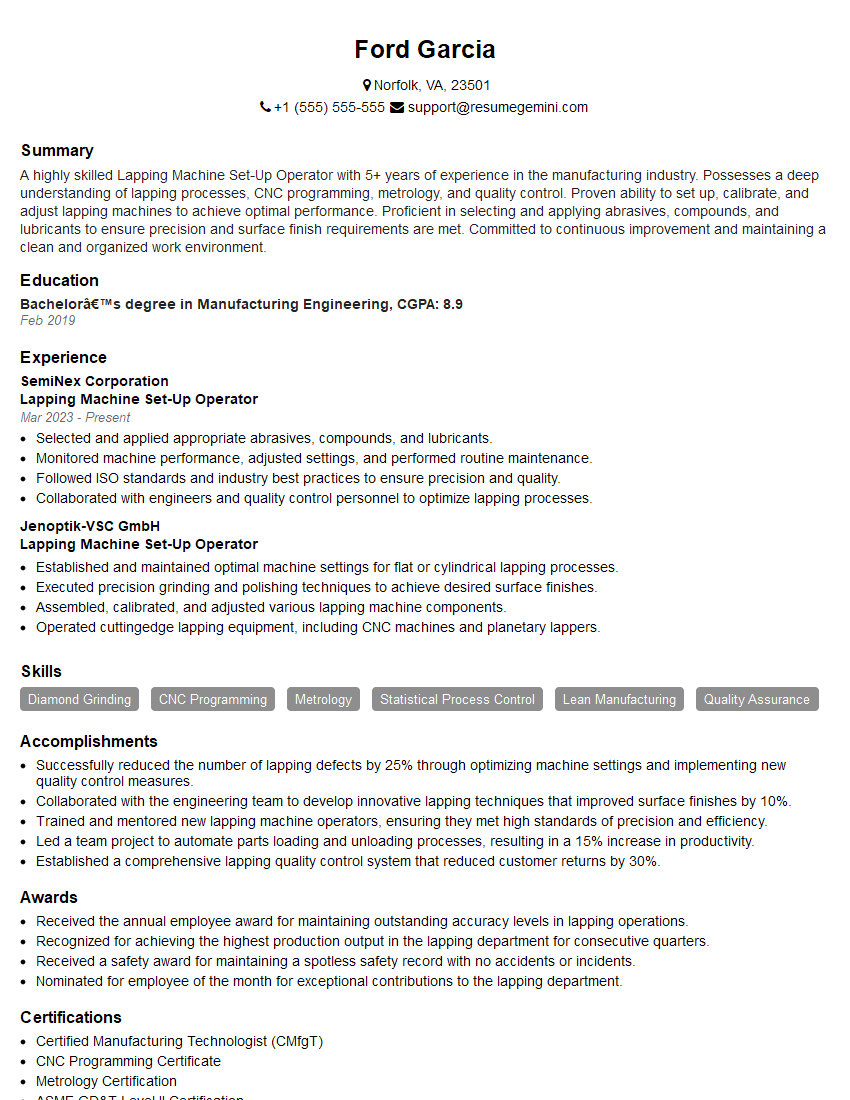

Ford Garcia

Lapping Machine Set-Up Operator

Summary

A highly skilled Lapping Machine Set-Up Operator with 5+ years of experience in the manufacturing industry. Possesses a deep understanding of lapping processes, CNC programming, metrology, and quality control. Proven ability to set up, calibrate, and adjust lapping machines to achieve optimal performance. Proficient in selecting and applying abrasives, compounds, and lubricants to ensure precision and surface finish requirements are met. Committed to continuous improvement and maintaining a clean and organized work environment.

Education

Bachelor’s degree in Manufacturing Engineering

February 2019

Skills

- Diamond Grinding

- CNC Programming

- Metrology

- Statistical Process Control

- Lean Manufacturing

- Quality Assurance

Work Experience

Lapping Machine Set-Up Operator

- Selected and applied appropriate abrasives, compounds, and lubricants.

- Monitored machine performance, adjusted settings, and performed routine maintenance.

- Followed ISO standards and industry best practices to ensure precision and quality.

- Collaborated with engineers and quality control personnel to optimize lapping processes.

Lapping Machine Set-Up Operator

- Established and maintained optimal machine settings for flat or cylindrical lapping processes.

- Executed precision grinding and polishing techniques to achieve desired surface finishes.

- Assembled, calibrated, and adjusted various lapping machine components.

- Operated cuttingedge lapping equipment, including CNC machines and planetary lappers.

Accomplishments

- Successfully reduced the number of lapping defects by 25% through optimizing machine settings and implementing new quality control measures.

- Collaborated with the engineering team to develop innovative lapping techniques that improved surface finishes by 10%.

- Trained and mentored new lapping machine operators, ensuring they met high standards of precision and efficiency.

- Led a team project to automate parts loading and unloading processes, resulting in a 15% increase in productivity.

- Established a comprehensive lapping quality control system that reduced customer returns by 30%.

Awards

- Received the annual employee award for maintaining outstanding accuracy levels in lapping operations.

- Recognized for achieving the highest production output in the lapping department for consecutive quarters.

- Received a safety award for maintaining a spotless safety record with no accidents or incidents.

- Nominated for employee of the month for exceptional contributions to the lapping department.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- CNC Programming Certificate

- Metrology Certification

- ASME GD&T Level II Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lapping Machine Set-Up Operator

- Highlight your technical skills: Emphasize your proficiency in CNC programming, metrology, and statistical process control.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your work, such as improved surface finish quality or reduced cycle times.

- Showcase your attention to detail: Describe your ability to set up and calibrate lapping machines with precision and accuracy.

- Emphasize your commitment to quality: Highlight your understanding of ISO standards and your dedication to producing high-quality parts.

Essential Experience Highlights for a Strong Lapping Machine Set-Up Operator Resume

- Established and maintained optimal machine settings for flat or cylindrical lapping processes to achieve desired surface finishes

- Assembled, calibrated, and adjusted various lapping machine components to ensure precision and accuracy

- Operated cutting-edge lapping equipment, including CNC machines and planetary lappers, to execute precision grinding and polishing techniques

- Selected and applied appropriate abrasives, compounds, and lubricants based on material properties and surface finish requirements

- Monitored machine performance, adjusted settings, and performed routine maintenance to ensure optimal operation

- Followed ISO standards and industry best practices to ensure precision, quality, and adherence to specifications

Frequently Asked Questions (FAQ’s) For Lapping Machine Set-Up Operator

What is the primary role of a Lapping Machine Set-Up Operator?

The primary role of a Lapping Machine Set-Up Operator is to set up, calibrate, and adjust lapping machines to achieve optimal performance and precision in grinding and polishing processes.

What are the key skills required for this role?

Key skills for a Lapping Machine Set-Up Operator include CNC programming, metrology, statistical process control, and a deep understanding of lapping processes.

What are the typical industries where Lapping Machine Set-Up Operators are employed?

Lapping Machine Set-Up Operators are commonly employed in the manufacturing, automotive, aerospace, and electronics industries.

What is the career growth potential for this role?

With experience and additional training, Lapping Machine Set-Up Operators can advance to roles such as Quality Control Inspector, Manufacturing Engineer, or Production Supervisor.

What are the safety precautions that Lapping Machine Set-Up Operators must observe?

Lapping Machine Set-Up Operators must wear appropriate safety gear, follow lockout/tagout procedures, and be aware of potential hazards such as rotating machinery and sharp edges.

What are the challenges faced by Lapping Machine Set-Up Operators?

Challenges faced by Lapping Machine Set-Up Operators include maintaining precision and accuracy in the setup and operation of machines, working with a variety of materials and surface finishes, and ensuring adherence to quality standards.

What are the latest trends in lapping technology?

Recent trends in lapping technology include the use of advanced materials, automation, and precision metrology techniques to improve efficiency, accuracy, and surface finish quality.

What professional development opportunities are available for Lapping Machine Set-Up Operators?

Lapping Machine Set-Up Operators can enhance their skills through training programs, workshops, and certifications offered by manufacturers, industry associations, and educational institutions.