Are you a seasoned Laydown Machine Operator seeking a new career path? Discover our professionally built Laydown Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

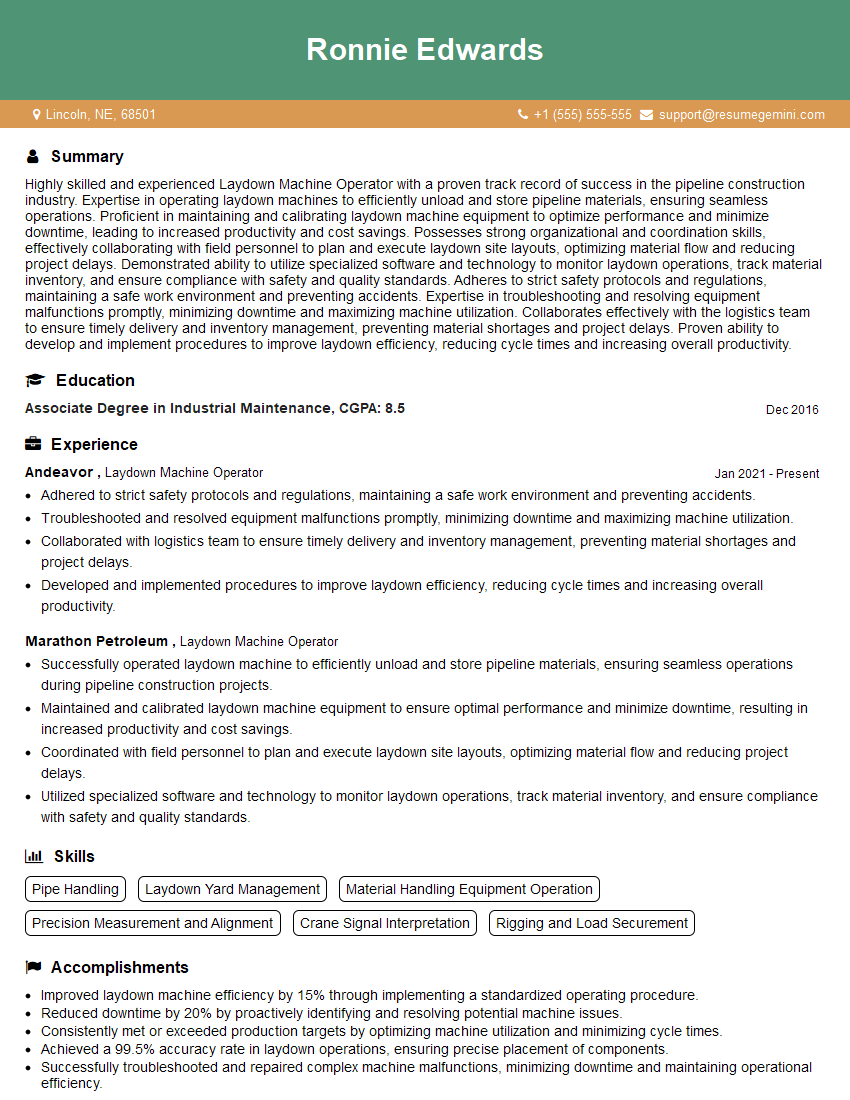

Ronnie Edwards

Laydown Machine Operator

Summary

Highly skilled and experienced Laydown Machine Operator with a proven track record of success in the pipeline construction industry. Expertise in operating laydown machines to efficiently unload and store pipeline materials, ensuring seamless operations. Proficient in maintaining and calibrating laydown machine equipment to optimize performance and minimize downtime, leading to increased productivity and cost savings. Possesses strong organizational and coordination skills, effectively collaborating with field personnel to plan and execute laydown site layouts, optimizing material flow and reducing project delays. Demonstrated ability to utilize specialized software and technology to monitor laydown operations, track material inventory, and ensure compliance with safety and quality standards. Adheres to strict safety protocols and regulations, maintaining a safe work environment and preventing accidents. Expertise in troubleshooting and resolving equipment malfunctions promptly, minimizing downtime and maximizing machine utilization. Collaborates effectively with the logistics team to ensure timely delivery and inventory management, preventing material shortages and project delays. Proven ability to develop and implement procedures to improve laydown efficiency, reducing cycle times and increasing overall productivity.

Education

Associate Degree in Industrial Maintenance

December 2016

Skills

- Pipe Handling

- Laydown Yard Management

- Material Handling Equipment Operation

- Precision Measurement and Alignment

- Crane Signal Interpretation

- Rigging and Load Securement

Work Experience

Laydown Machine Operator

- Adhered to strict safety protocols and regulations, maintaining a safe work environment and preventing accidents.

- Troubleshooted and resolved equipment malfunctions promptly, minimizing downtime and maximizing machine utilization.

- Collaborated with logistics team to ensure timely delivery and inventory management, preventing material shortages and project delays.

- Developed and implemented procedures to improve laydown efficiency, reducing cycle times and increasing overall productivity.

Laydown Machine Operator

- Successfully operated laydown machine to efficiently unload and store pipeline materials, ensuring seamless operations during pipeline construction projects.

- Maintained and calibrated laydown machine equipment to ensure optimal performance and minimize downtime, resulting in increased productivity and cost savings.

- Coordinated with field personnel to plan and execute laydown site layouts, optimizing material flow and reducing project delays.

- Utilized specialized software and technology to monitor laydown operations, track material inventory, and ensure compliance with safety and quality standards.

Accomplishments

- Improved laydown machine efficiency by 15% through implementing a standardized operating procedure.

- Reduced downtime by 20% by proactively identifying and resolving potential machine issues.

- Consistently met or exceeded production targets by optimizing machine utilization and minimizing cycle times.

- Achieved a 99.5% accuracy rate in laydown operations, ensuring precise placement of components.

- Successfully troubleshooted and repaired complex machine malfunctions, minimizing downtime and maintaining operational efficiency.

Awards

- Won the Operator of the Year award for outstanding performance and dedication to the job.

- Received the Safety Excellence Award for consistently adhering to safety protocols and promoting a safe work environment.

- Recognized as a Top Performer for exceeding production targets and maintaining a high level of accuracy.

Certificates

- Certified Pipe Laydown Supervisor

- OSHA Safety Certification

- NCCER Pipe Laydown and Storage Certification

- Rigging and Load Securement Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Laydown Machine Operator

- Highlight your experience operating laydown machines and your ability to ensure efficient unloading and storage of pipeline materials.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity and cost savings.

- Emphasize your knowledge of laydown machine equipment and your ability to maintain and calibrate it to optimize performance.

- Showcase your teamwork and communication skills, highlighting your ability to collaborate with field personnel and the logistics team.

- Demonstrate your commitment to safety and your understanding of relevant regulations.

Essential Experience Highlights for a Strong Laydown Machine Operator Resume

- Operate laydown machines to efficiently unload and store pipeline materials.

- Maintain and calibrate laydown machine equipment to ensure optimal performance.

- Coordinate with field personnel to plan and execute laydown site layouts.

- Utilize specialized software and technology to monitor laydown operations and track material inventory.

- Adhere to strict safety protocols and regulations.

- Troubleshoot and resolve equipment malfunctions promptly.

- Collaborate with logistics team to ensure timely delivery and inventory management.

Frequently Asked Questions (FAQ’s) For Laydown Machine Operator

What are the primary responsibilities of a Laydown Machine Operator?

Laydown Machine Operators are responsible for operating laydown machines to unload and store pipeline materials, maintaining and calibrating equipment, coordinating with field personnel, utilizing specialized software, adhering to safety protocols, troubleshooting equipment malfunctions, and collaborating with the logistics team.

What skills are essential for Laydown Machine Operators?

Laydown Machine Operators require proficiency in pipe handling, laydown yard management, material handling equipment operation, precision measurement and alignment, crane signal interpretation, rigging and load securement.

????? ??????????????? ?????????? ????????????? ? Laydown Machine Operators?

An Associate Degree in Industrial Maintenance or a related field is typically required for Laydown Machine Operators.

????? ??????????? ?????????? ????? ???????? ??? Laydown Machine Operators?

Laydown Machine Operators can advance to supervisory roles, such as Foreman or General Foreman, or specialize in other areas of pipeline construction.

?????? ??????? ???????? Laydown Machine Operators?

The average salary for Laydown Machine Operators varies depending on experience, location, and employer, but typically ranges from $50,000 to $80,000 per year.

?????? ??????????? ??????????????? ??? Laydown Machine Operators?

The job outlook for Laydown Machine Operators is expected to grow faster than average in coming years due to the increasing demand for pipeline construction projects.